Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In the world of packaging, ensuring the safety and integrity of products during transit is paramount. This is where the corrugated box drop test comes

Ultraviolet (UV) rays can have detrimental effects on product packaging, leading to faded colors, weakened materials, and compromised product integrity. In industries where products are

Secondary packaging plays a vital role in the supply chain, influencing marketing, protection, and logistics. It’s an integral component for businesses in various industries. In

Launching a product in a retail chain or club store is a significant milestone for any brand. However, this process can come with challenges, particularly

Millennials, born roughly between 1981 and 1996, have become a dominant force in the consumer market. Their unique preferences and values significantly influence packaging trends.

Magnetic rigid boxes have become a hallmark of luxury packaging, offering a blend of functionality, elegance, and durability. These boxes are a popular choice for

Point of Purchase (POP) displays are a crucial element in the world of retail marketing. They play a significant role in catching the eye of

In the competitive retail landscape, the clarity and legibility of pouch packaging play a pivotal role in customer engagement and brand communication. A well-designed package

In the world of product manufacturing and retail, packaging plays a crucial role in protecting products, attracting consumers, and conveying brand messages. Among the various

In the competitive and dynamic field of packaging, buyers are continually seeking ways to enhance their packaging strategies. From increasing efficiency and sustainability to reducing

Corrugated boxes, commonly referred to as cardboard boxes, are a ubiquitous presence in our day-to-day lives. From moving houses to shipping products, these boxes are

In the dynamic world of packaging, embossing stands out as a distinguished technique that adds depth and texture to product packaging, elevating the consumer experience.

When you think about dental care, your mind might immediately go to toothbrushes, floss, and toothpaste. But behind the scenes, a critical aspect of the

Gift-giving is a timeless tradition, and the packaging plays a crucial role in making the gesture even more special. When it comes to choosing the

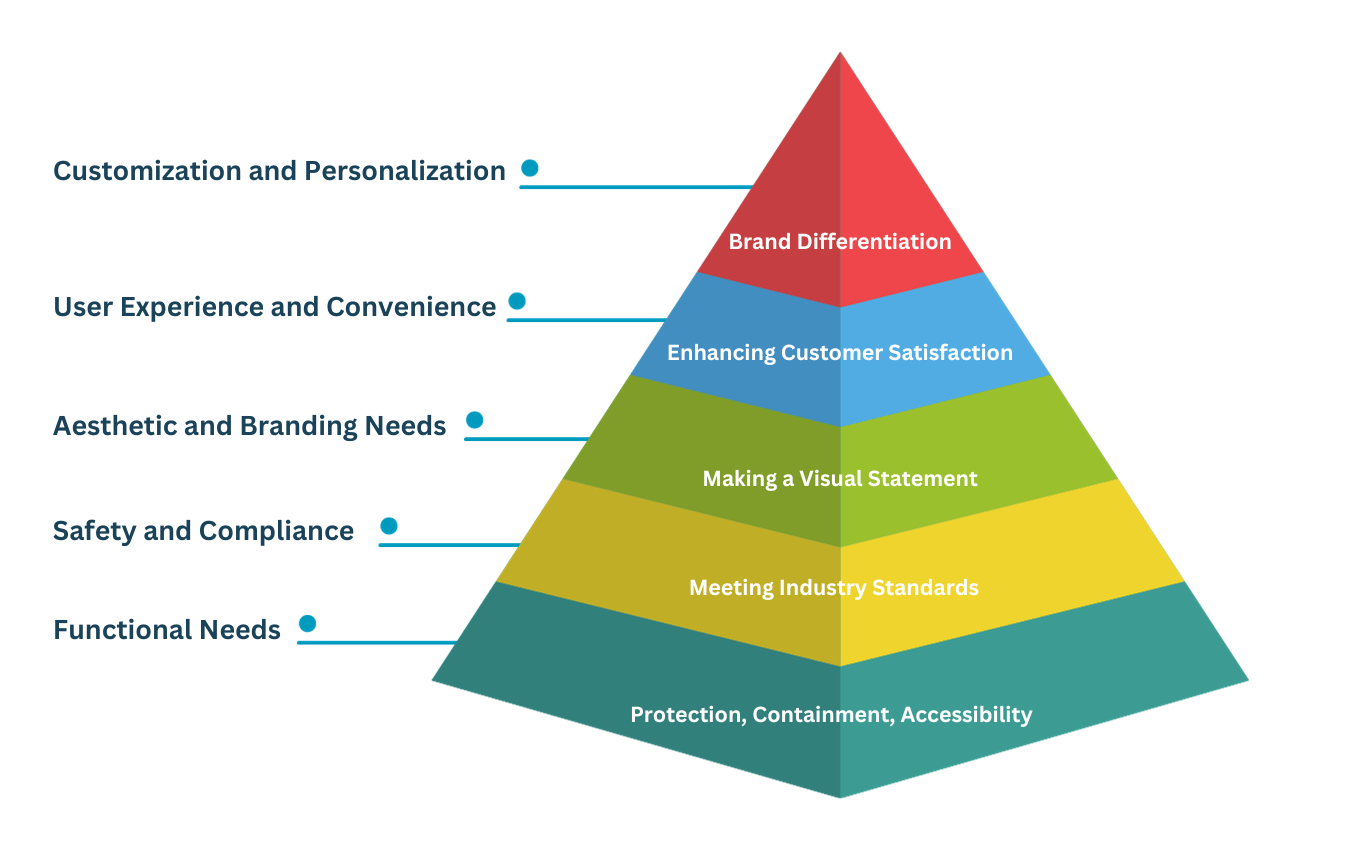

When it comes to packaging, it’s easy to dismiss it as merely a wrapper for the product. However, packaging serves a crucial role in not

Packaging is not merely a practical aspect of shipping; it’s also a statement about your brand’s commitment to quality and protection. When it comes to

In the realm of product management, the relationship between packaging and storage is often overlooked, yet it is a critical aspect of operational efficiency and

The fascinating world of protective packaging has seen considerable evolution over the decades. These advancements have been driven by the needs of various industries, emerging

Transitioning from off-the-shelf packaging to custom solutions is a significant milestone for many businesses. This shift not only aligns packaging more closely with brand identity

Packaging for toddler toys is a unique segment that requires a thoughtful approach, balancing safety, engagement, and often, an educational aspect. This blog post explores

Packaging plays a pivotal role in the world of snacks, influencing everything from freshness and shelf life to branding and consumer appeal. With a multitude