Wholesale Thermoform Packaging Insert Supplier

Custom Thermoform Inserts

Prevent your product from shifting and becoming damaged, and improve the accessibility and organization of your product within a package. Thermoform inserts can be customize by size, shape, and material used to best support your product. Medical, electronic, industrial and retail solutions available.

Wholesale Thermoform Packaging Insert Supplier

Custom Thermoform Inserts

Prevent your product from shifting and becoming damaged, and improve the accessibility and organization of your product within a package. Thermoform inserts can be customize by size, shape, and material used to best support your product. Medical, electronic, industrial and retail solutions available.

What is a Thermoform Packaging Insert?

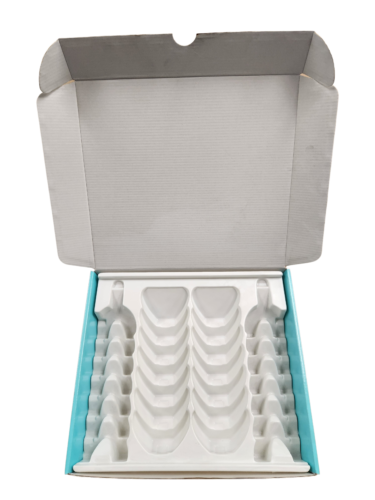

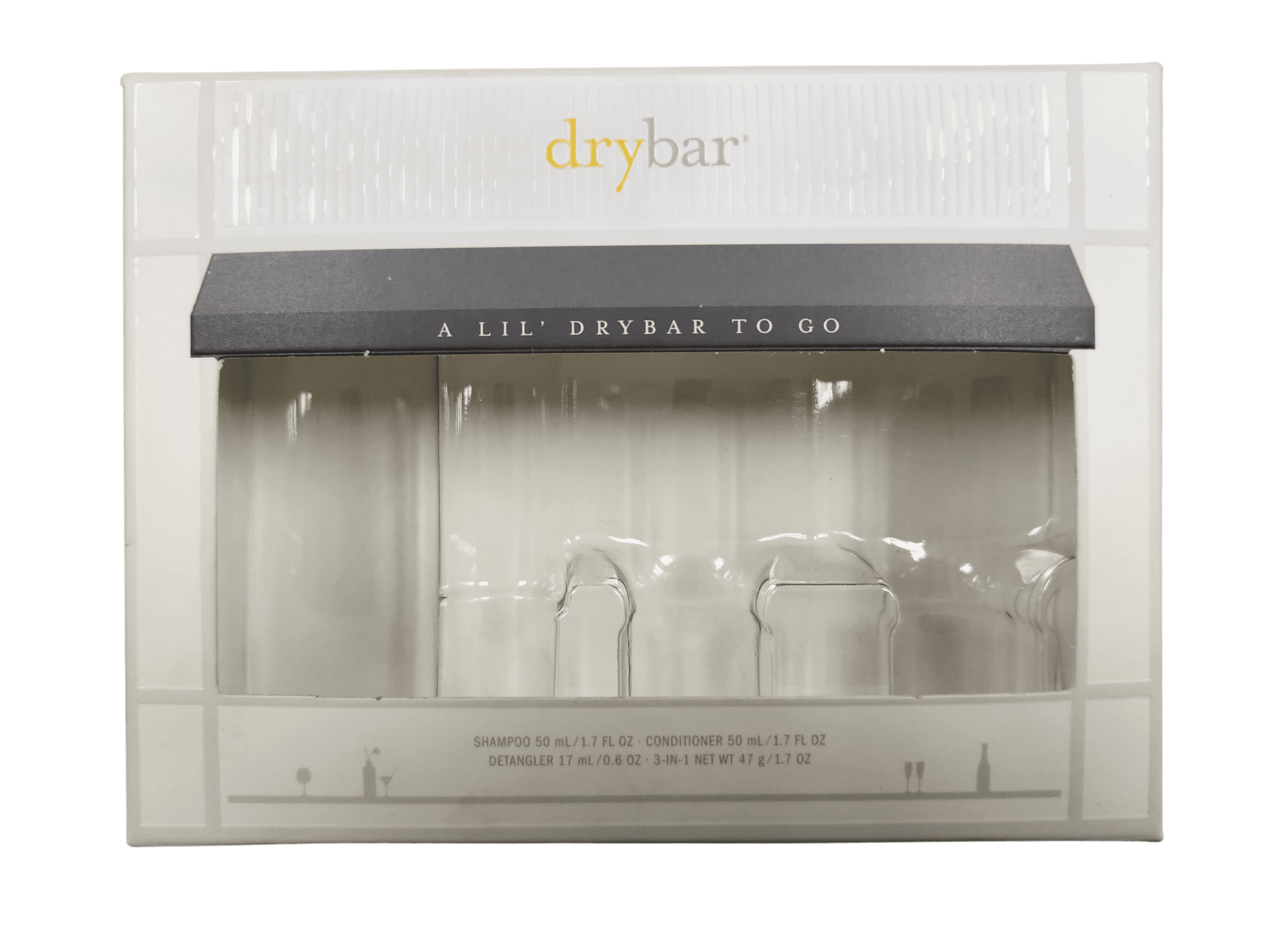

Thermoform packaging inserts are specialized components crafted from thermoplastic materials that are heated and molded into precise shapes to securely hold and protect products during shipping and presentation. These inserts are designed to fit snugly within packaging boxes, offering tailored compartments that cradle products and prevent movement, ensuring they arrive at their destination in pristine condition.

Thermoform inserts find applications across various industries, such as electronics, medical, and retail packaging, where they enhance product presentation and safeguard delicate items during transit. Their benefits include precision fit, durability, and protection against electrostatic discharge (ESD) in electronic components, offering tailored solutions for product protection and presentation.

Thermoform Insert Products

Our thermoform insert products are tailored to your exact packaging needs, with customization options extending to structural design. From precise product cavities to secure compartments, we create thermoform inserts that provide optimal protection and organization, ensuring your items are delivered safely and professionally presented.

Applications

Incorporate thermoform inserts within corrugated boxes to ensure the secure and damage-free shipping of fragile items, with the inserts expertly fitted to protect your products. See our selection of corrugated boxes.

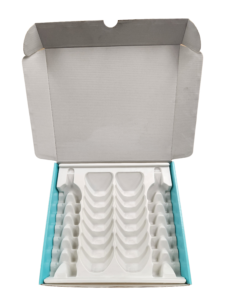

Elevate your folding carton packaging with custom thermoform inserts, providing an organized and secure environment within the box for delicate or valuable items, guaranteeing their pristine condition upon arrival. Checkout our selection of folding cartons.

Enhance the presentation and protection of luxury items within rigid box packaging by integrating thermoform inserts, tailored to cradle and safeguard your products with elegance and precision. View our rigid box styles.

Thermoform inserts play a crucial role in electronic packaging, where they provide a precise and secure fit for delicate components, protecting them from static discharge and physical damage during shipping. Their precision and durability make them a preferred choice for ensuring the safe transit of sensitive electronic devices and parts.

Transform retail packaging with inserts that create an attractive and organized presentation, enhancing the customer’s unboxing experience and safeguarding merchandise during transit. Learn more about our retail packaging.

Secure industrial equipment and tools during transport with inserts strategically placed within packaging, effectively shielding them from impacts and vibrations. Checkout our industrial packaging solutions.

Safeguard delicate medical instruments and equipment with inserts designed for precise placement within medical packaging, ensuring they arrive intact and sterile, ready for immediate use in healthcare settings. Learn more about our medical packaging.

For custom foam insert solutions tailored to your specific packaging needs and industry requirements, please don’t hesitate to reach out to our team at Brown Packaging. We’re here to assist you in optimizing your packaging with expertly designed foam inserts that ensure the safe transit and presentation of your products. Contact us today for personalized guidance and solutions.

Popular Products

Multi-layer inserts provide an extra layer of protection, especially for delicate or multiple items. These inserts feature customizable layers to secure products of various sizes or fragility levels. Tailor them to your exact specifications to ensure each product is securely cradled for safe shipping.

Product cavities are precision-designed to protect uniquely shaped items. Crafted from thermoform materials, these inserts are customized to match your product’s contours precisely. They ensure a snug fit that prevents movement and damage during shipping, making them ideal for specialty or fragile products.

Our trays offer a structured packaging solution for various products. These inserts provide stability and organization. Our trays create a reliable foundation for your items, ensuring they remain well-protected and neatly arranged.

Labels are a simple yet effective way to enhance your packaging presentation. Customize labels with your branding, product information, or handling instructions to ensure your packaging is both informative and visually appealing.

Thermoform insert printed pads offer a combination of precise product protection and branding opportunities. These customized pads are designed to securely hold items within packaging while displaying your brand logo or product information, enhancing both presentation and protection.

Thermoform Insert Materials

Selecting the right thermoform plastic material is crucial to meet your specific packaging requirements. Whether you need a clear, rigid plastic for product visibility or an anti-static material for sensitive electronics, our expertise ensures you choose the ideal material to protect and showcase your products effectively.

Polyethylene Terephthalate

Highly flexible and clear, PET is the most common thermoform packaging material. Variations include: APET, PETG, and RPET.

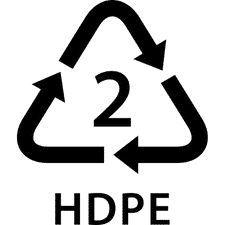

High Density Polyethylene

Resistant to cold temperatures, impacts, chemical interactions. Popular in food and beverage products.

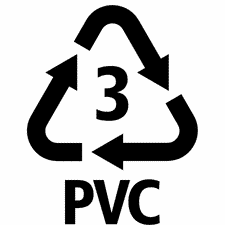

Polyvinyl Chloride

High impact resistant and rigid, PVC is often used in medical and industrial applications.

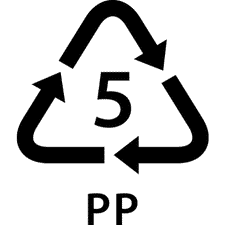

Polypropylene

Chemical resistant and flexible, PP is used to package food, electronic, and medical products.

Other Plastics

Acrylonitrile Butadiene Styrene (ABS), High Impact Polystyrene (HIPS), and more.

Interested In Thermoform Inserts?

Frequently Asked Questions

Thermoform inserts are recommended for applications that require strong, durable, and rigid inserts without having to sacrifice too much packaging space for cushioning and protecting the product as thermoform is designed very thin.

Yes, we do offer recyclable and other sustainable materials. Contact us and we can go over sustainable options with you that best fit your project.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Lead times can vary depending on your design, quantity, materials and other factors. To get an accurate lead time for your project, contact us and a packaging expert will assist you.

Alternative inserts include corrugated, chipboard and foam. Corrugated and chipboard can be manufactured at different levels of thickness and strength. Foam can be manufactured with different materials and densities.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order.