Wholesale Shrink and Skin Film Supplier

Shrink and Skin Film Packaging

We are a one stop packaging supplier for businesses in need of plastic packaging. Checkout our selection of shrink and skin film products that are available in all standard sizes, thickness, and material.

Wholesale Shrink and Skin Film Supplier

Shrink and Skin Film Packaging

We are a one stop packaging supplier for businesses in need of plastic packaging. Checkout our selection of shrink and skin film products that are available in all standard sizes, thickness, and material.

Our Shrink and Skin Film Products

Shrink film, plastic shrink wrap, bundling film, and skin film protect, secure and keep your product clean while maintaining the professional appearance you desire. We have an extensive selection of shrink and skin film ideal for any packaging need you may have.

Select The Right Film Shrink, Skin, and Vacuum Film

Shrink Film

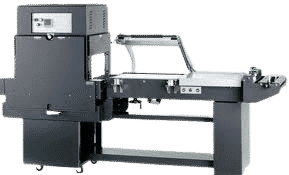

Shrink Film, also known as shrink wrap, is made up of polymer plastic material that shrinks when heat is applied. To apply shrink wrap you must first wrap the pallet or product first, then apply heat. Heat can be applied by a heat tunnel on a conveyor or by a handheld heat gun. Once shrunk, the covered merchandise or pallet will be tightly held by the wrap.

- High resistance to impact. tears and punctures

- Strong holding force

- High gloss surface and great transparency for reverse printing

- Protects products during storage, shipment, and in display

- Extends the shelf-life and presentation of products

- Cost efficient compared to alternative solutions

Typically, shrink wrap is used to protect and package a single product or multiple products bundled together. Here are common packaging applications for shrink film:

- Bottle beverage bundles such as soda, water, juice, and sports drinks

- Used to hold pallet loads together for transport or storage

- Big and small appliances (residential and commercial)

- Electronics equipment and devices

- Sporting goods

- Toys

Skin Film

Skin film is heated film (Surlyn or Polyethylene plastic) that is used to seal products tightly against a corrugated, plastic and paperboard materials. A machine vacuum pulls the film into the backing, which creates a highly visible and tamper-evident package.

- Significantly improves shelf-life and reduces waste by preserving food products.

- Board material can be customized with graphics and print.

- Vacuum sealed products are restricted in movement during storage and transit, allowing product to maintain original presentation.

- Easy user accessibility and convenience when unsealing a product.

- Improved product visibility on shelves.

Skin film is widely used among a variety of products such as:

- Electronic parts and devices

- Auto parts

- Medical devices, equipment, and utensils

- Retail products

Vacuum Film

Vacuum film, also referred to as vacuum packaging film, is a type of packaging material used in vacuum packaging processes. Vacuum packaging involves removing air from the packaging around a product before sealing it. This process helps extend the shelf life of perishable goods by reducing oxygen levels, which slows down the growth of spoilage-causing microorganisms.

Extended Shelf Life: Vacuum packaging with vacuum film significantly extends the shelf life of products, particularly perishable foods, by reducing oxygen levels and inhibiting the growth of spoilage-causing microorganisms.

Preservation of Freshness: By removing air and minimizing exposure to oxygen, vacuum packaging helps preserve the natural freshness, flavors, colors, and textures of products.

Prevention of Freezer Burn: Vacuum-sealed products are protected from freezer burn, which occurs when moisture in frozen items evaporates and re-condenses, leading to a deterioration in quality.

Enhanced Product Presentation: Vacuum packaging with transparent vacuum film allows customers to see the product’s appearance and quality, promoting consumer trust and satisfaction.

Reduced Food Waste: Vacuum packaging helps reduce food waste by maintaining product quality for longer periods, allowing products to be stored without deteriorating rapidly.

Food Preservation: Vacuum film is extensively used to package a wide range of perishable foods, including meats, poultry, fish, dairy products, fruits, and vegetables, to extend their shelf life and maintain freshness.

Cheese and Deli Products: Vacuum-sealed packaging helps preserve the flavor, texture, and aroma of cheese and deli products, ensuring they stay appetizing for longer periods.

Prepared Meals: Vacuum packaging is used for ready-to-eat meals, allowing for extended shelf life without the need for excessive preservatives.

Bakery Items: Baked goods like bread, pastries, and cakes are vacuum-sealed to maintain their moisture and prevent staleness.

Coffee and Tea: Vacuum film helps keep coffee and tea fresh by preventing the loss of flavor and aroma due to exposure to air.

Nuts and Snacks: Vacuum-sealed packaging prevents nuts and snack items from becoming stale and helps maintain their crunchiness.

Processed Meats: Processed meats like sausages, bacon, and jerky are vacuum-sealed to extend their shelf life while retaining their quality.