Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In the world of packaging, making a memorable impression is crucial. Packaging not only protects and delivers products but also serves as a powerful branding

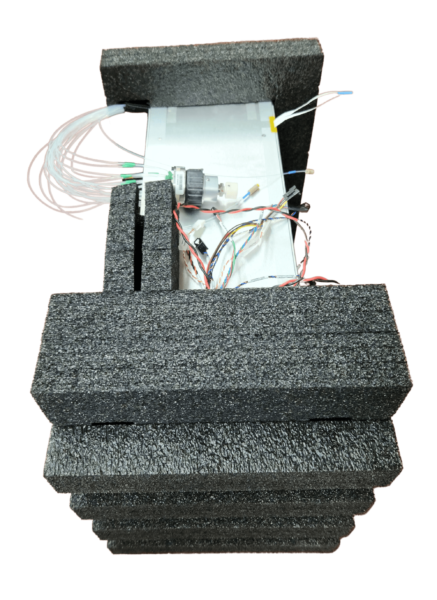

Packaging plays a crucial role in protecting products during transit and storage. Among the various materials used for packaging, polyethylene foam stands out as an

Polypropylene, often referred to as PP plastic, is the second most widely used plastic globally, praised for its remarkable durability, strength, and resistance to various

Packaging is a crucial component of product safety and marketing. Over the years, innovative materials have surfaced to enhance packaging capabilities, with one of the

High Impact Polystyrene, commonly known as HIPS, is a versatile and widely used thermoplastic renowned for its unique blend of properties. This material is crucial

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression.

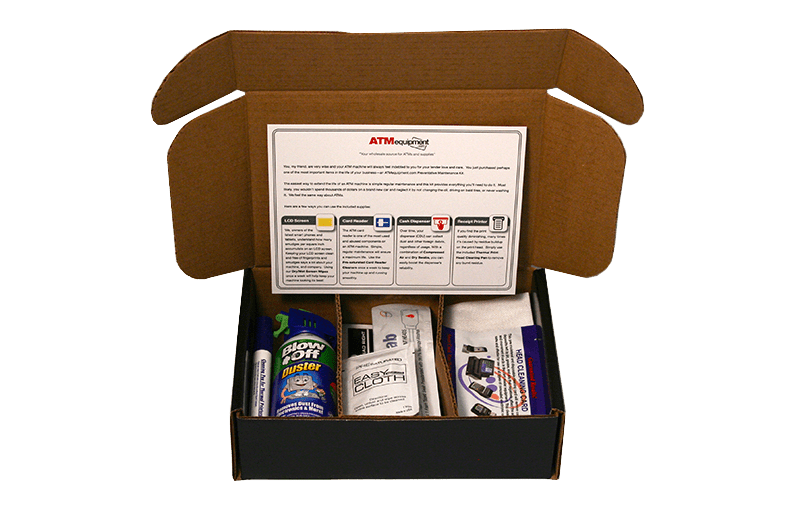

Creating an effective Point of Purchase (POP) display can be a game changer for any retail business, influencing buying decisions and enhancing product visibility. For

The final steps in deploying a permanent and semi-permanent Point of Purchase (POP) display involve the logistics of distribution and the specifics of installation. Effective

Food packaging waste is a pressing environmental issue that demands our attention. Excessive packaging, single-use plastics, limited recycling facilities, and consumer habits all contribute to

Reverse Tuck End (RTE) cartons are a popular packaging solution known for their unique design and versatility. In this blog, we will delve into the

In a diverse consumer market, the effectiveness of your packaging strategy can hinge on how well it resonates with specific customer segments. Customization for different

The selection of materials and the production process are critical aspects of creating a Point of Purchase (POP) display that not only captures attention but

When it comes to retail marketing, Point of Purchase (POP) displays are essential for capturing customer attention and promoting your products effectively. The size and

In the world of packaging, there’s a constant tug-of-war between two critical factors: extending the shelf life of products and controlling costs. This delicate balancing

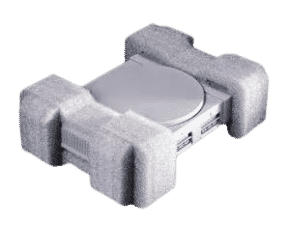

When it comes to packaging, especially for delicate and fragile items, foam materials play a crucial role in ensuring the safety and protection of the

For those well-versed in the basics of packaging, a deeper dive into the technicalities of custom folding cartons can reveal a world of intricate details

In the packaging industry, the design of a carton can significantly impact both the presentation and functionality of a product. Among the various styles available,

Corrugated boxes are more than mere containers; they’re the culmination of engineering, design, and environmental consideration. This advanced guide delves into the nuances of corrugated

The world of packaging design is rich with innovative solutions that cater to various product needs. Among these, Roll End Tuck Tops (RETT), Cherry Locks,

In today’s competitive market, understanding and optimizing the cost of your packaging is crucial for maintaining profitability and enhancing overall business performance. A thorough cost

In the dynamic world of packaging, two materials often stand at the forefront: traditional corrugated cardboard and its modern counterpart, plastic corrugated. While both have