Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In the highly competitive world of physical retail, every tiny detail counts when it comes to attracting customers and encouraging them to purchase your products.

Understanding consumer psychology is paramount to creating effective point of purchase (POP) displays. These strategically placed displays can significantly influence a customer’s decision to make

In the bustling world of retail, where competition is fierce and every inch of shelf space matters, staying ahead requires innovation. You’ve cultivated an exceptional

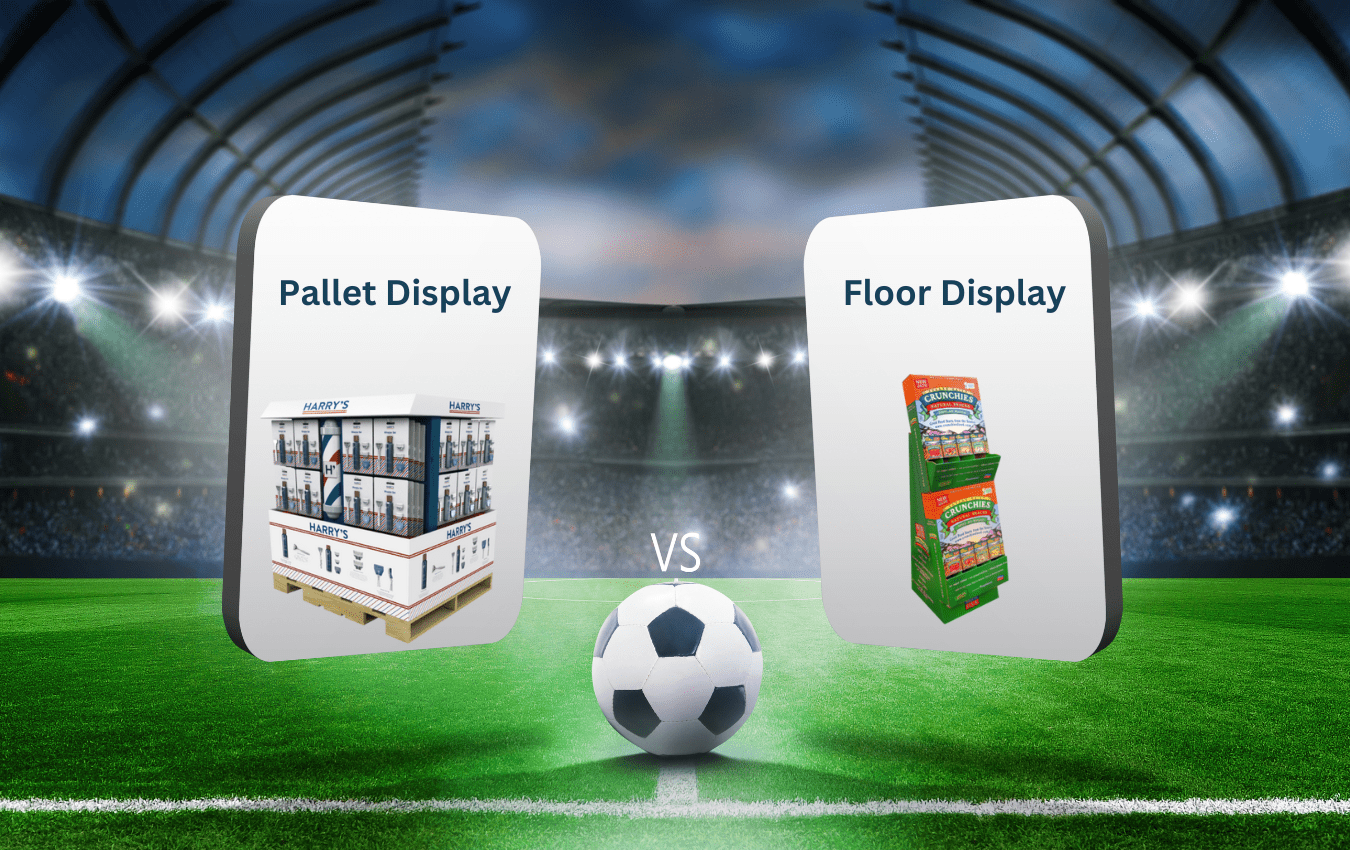

In the ever-evolving landscape of retail marketing, the art of product presentation plays a pivotal role in captivating consumers and driving sales. Two popular options

Sustainability has become a crucial issue in recent years, and more and more businesses are adopting sustainable practices to reduce their environmental impact. One area

Corrugated boxes, often seen as an ordinary tool for storage and transportation, possess versatility that goes beyond their humble reputation. From industries like e-commerce and

As the global food industry continues to expand and evolve, one factor remains constant: the importance of effective, efficient, and safe packaging. At the intersection

In the fiercely competitive world of retail, brand recognition is the key to success. Standing out amidst a sea of choices requires a strategic approach,

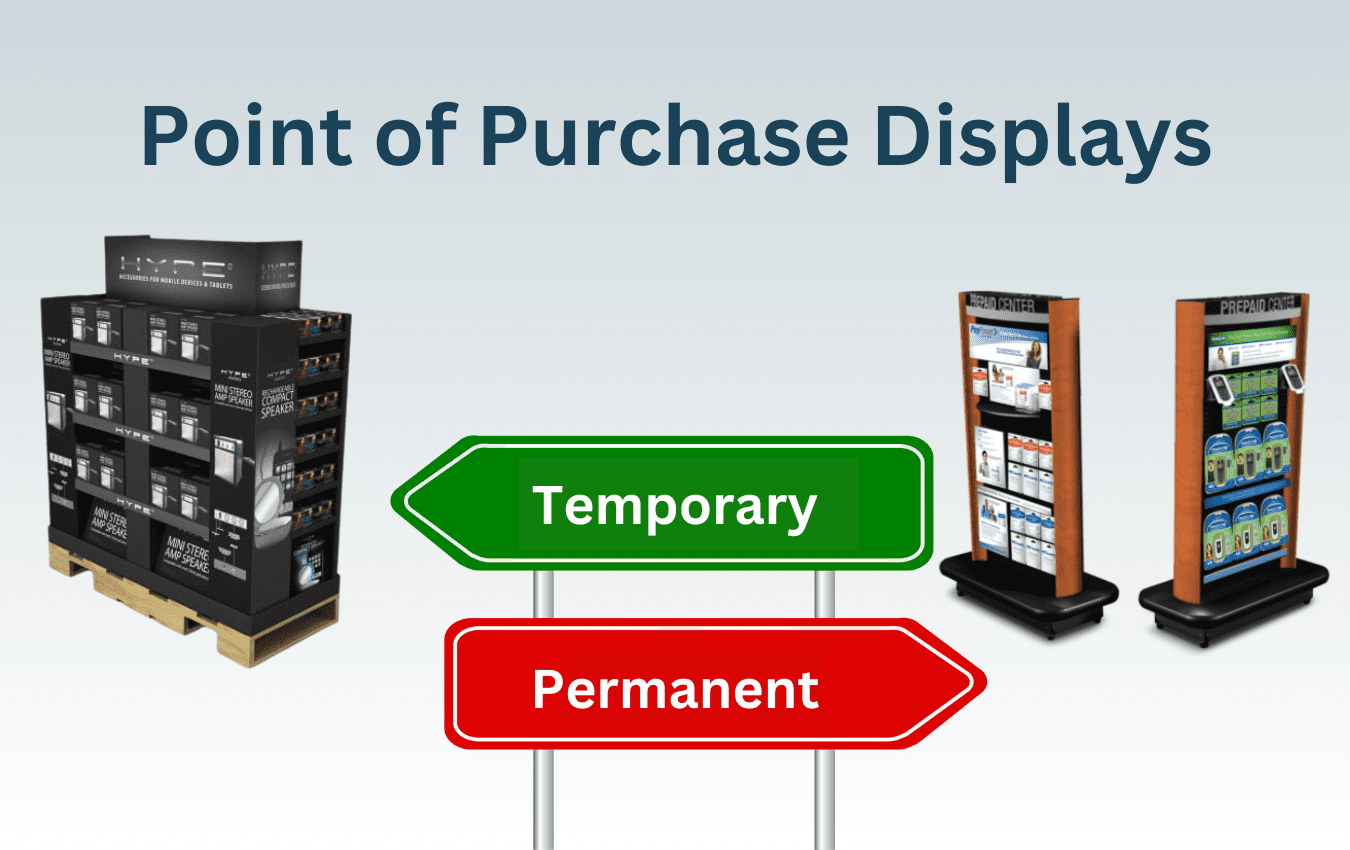

In the fast-paced world of retail, every moment counts when it comes to capturing the attention of customers and driving sales. This is where Point

In our increasingly eco-conscious society, it is becoming crucial for businesses to strive for sustainability in every possible area. One often-overlooked sector with considerable potential

In an increasingly competitive and environmentally conscious world, protective packaging has become an essential component of product manufacturing and delivery. The demand for efficient and

Packaging plays a crucial role in protecting products during transportation and handling. However, not all packaging materials, such as corrugated are created equal, and choosing

In the dynamic realm of retail, crafting the perfect display goes beyond just showcasing products – it’s about sparking customer interest, driving sales, and making

In the intricate world of retail, Point-of-Purchase (POP) displays play a critical role in influencing consumer decisions and driving sales. When it comes to choosing

Rigid boxes, also known as set-up boxes, are high-quality packaging boxes that offer an unmatched level of durability and sturdiness. They are often used for

In today’s fast-paced world, protecting fragile and valuable items during transportation is of utmost importance. Whether it’s delicate electronics, intricate machinery, or even perishable goods,

A pouch is a flexible packaging product which is made up of layers of plastic film, metalized, barrier film and other materials. Typically they are

In recent years, sustainability has become a key focus in various industries, including packaging. As companies strive to minimize their environmental footprint, innovative solutions are

The world of packaging design has undergone a remarkable transformation in recent years, with new and innovative designs emerging to meet the ever-changing needs of

Corrugated boxes are one of the most popular packaging materials used by businesses worldwide to ship and store their products. They are made of corrugated

As a packaging buyer, it is important to understand the regulations and requirements surrounding food labels to ensure that the packaging you purchase complies with