Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

High-speed automated packaging lines can run hundreds of cartons per minute, but only if the carton’s design and material are optimized for smooth feeding, folding,

Foam-in-corrugated hybrid inserts combine the cushioning properties of foam with the structural rigidity of corrugated board, creating a packaging solution that is both protective and

Board caliper—the thickness of paperboard—directly influences carton strength, folding behavior, print quality, and cost. Selecting the right caliper is a balancing act between performance requirements

Point-of-purchase (POP) displays come in two primary formats: reusable and disposable. Each option offers advantages depending on campaign goals, budget, and retail environment. Choosing the

Cross-merchandising is one of the most effective ways to increase basket size in retail. By pairing complementary products in a single point-of-purchase (POP) display, brands

POP displays must balance eye-catching branding with structural integrity. Inadequate load-bearing design can result in product sagging, leaning, or complete collapse, which not only risks

Folding carton style selection directly impacts packaging line efficiency, end-user experience, and the overall cost-to-deliver. Each design offers unique advantages in terms of assembly speed,

Choosing a folding carton isn’t just about the graphics or the style—it’s about how the structural design and substrate work in tandem. The right combination

Seasonal promotions are among the most powerful opportunities for brands to capture attention in retail environments. From holidays to back-to-school campaigns, point-of-purchase (POP) displays serve

Freight is one of the largest cost drivers in retail packaging programs. Point-of-purchase (POP) displays that look impressive on the floor may be inefficient to

Incorporating recycled fiber into corrugated board is essential for sustainability goals, but it directly affects the mechanical properties of packaging. Understanding how fiber composition influences

Score cracking—visible fiber breakage along a fold—can ruin a carton’s appearance, weaken its structure, and cause failures on automated lines. Understanding the causes and engineering

E-commerce packaging for pet products must endure far more stress than traditional retail packaging. Shipments face repeated drops, vibration, compression, and environmental fluctuations. Structural design,

Corrugated boxes lose a significant portion of their original compression strength during prolonged storage, especially under load. Understanding the mechanics of compression creep and the

E-commerce exposes folding cartons to more handling points, longer transit times, and harsher mechanical stresses than traditional retail distribution. Designing for these conditions requires careful

The Edge Crush Test (ECT) is a critical performance metric for corrugated boxes, directly correlating to stacking strength and load-bearing capacity. In the high-stress world

RSC boxes are widely used because they balance strength with cost efficiency. But not all RSC boxes are created equal. Buyers have to weigh board

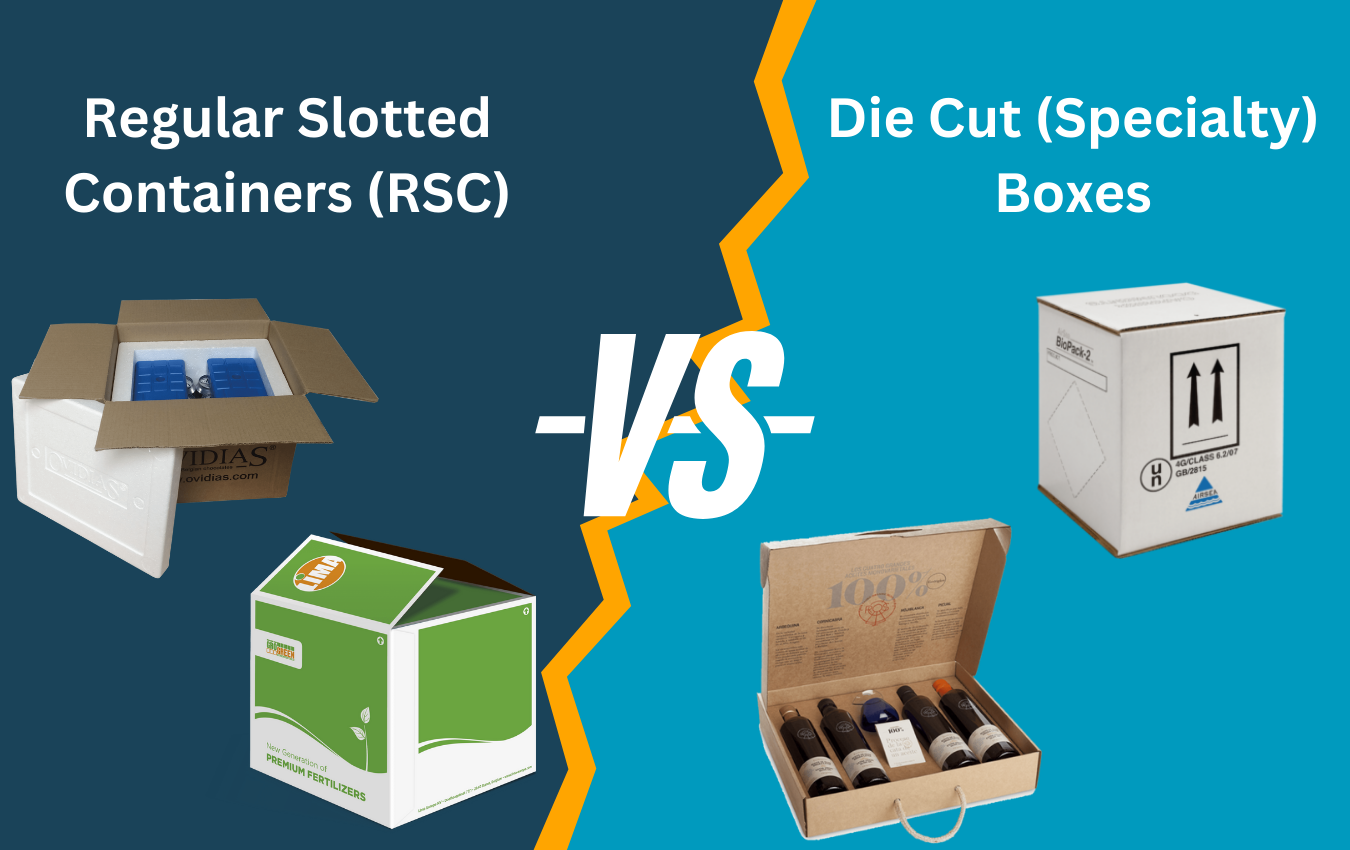

RSC boxes dominate corrugated packaging, but they aren’t always the best fit. Specialty box styles like Full Overlap (FOL), RETT mailers, and die-cut formats offer

In the competitive pet care industry, packaging graphics can be as influential as product quality when it comes to driving sales. For pet food, treats,

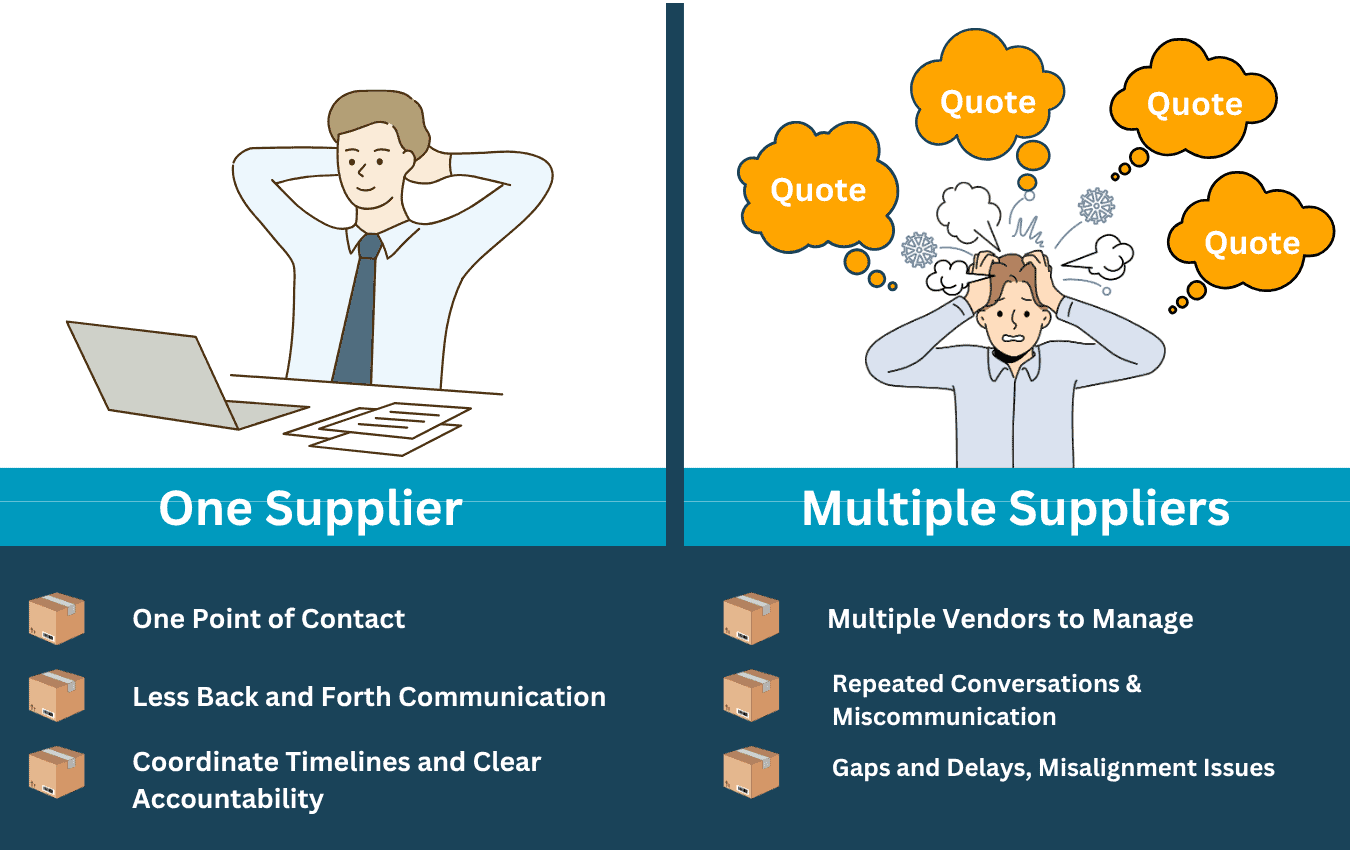

Managing packaging for your business is more than just ordering boxes and labels—it’s about sourcing the right materials, coordinating timelines, ensuring quality, and staying aligned

When it comes to packaging, cutting costs doesn’t mean cutting corners. The most cost-effective packaging solutions are those that balance performance, simplicity, and scalability. Whether