Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In the world of packaging and delivery, corrugated boxes have long been the workhorse of choice. Known for their durability, flexibility, and affordability, these boxes

Lithography and digital print are two of the most commonly used methods in packaging printing. They both have unique advantages and disadvantages, and understanding these

Packaging is a crucial aspect of any business that deals with physical products. Custom die-cut foam is a popular packaging material that offers excellent cushioning

Effective packaging can play a critical role in the success of any business. The right type of packaging can make all the difference when it

In today’s fast-paced world, protective packaging plays a crucial role in safeguarding products during transportation, handling, and storage. It acts as a shield against various

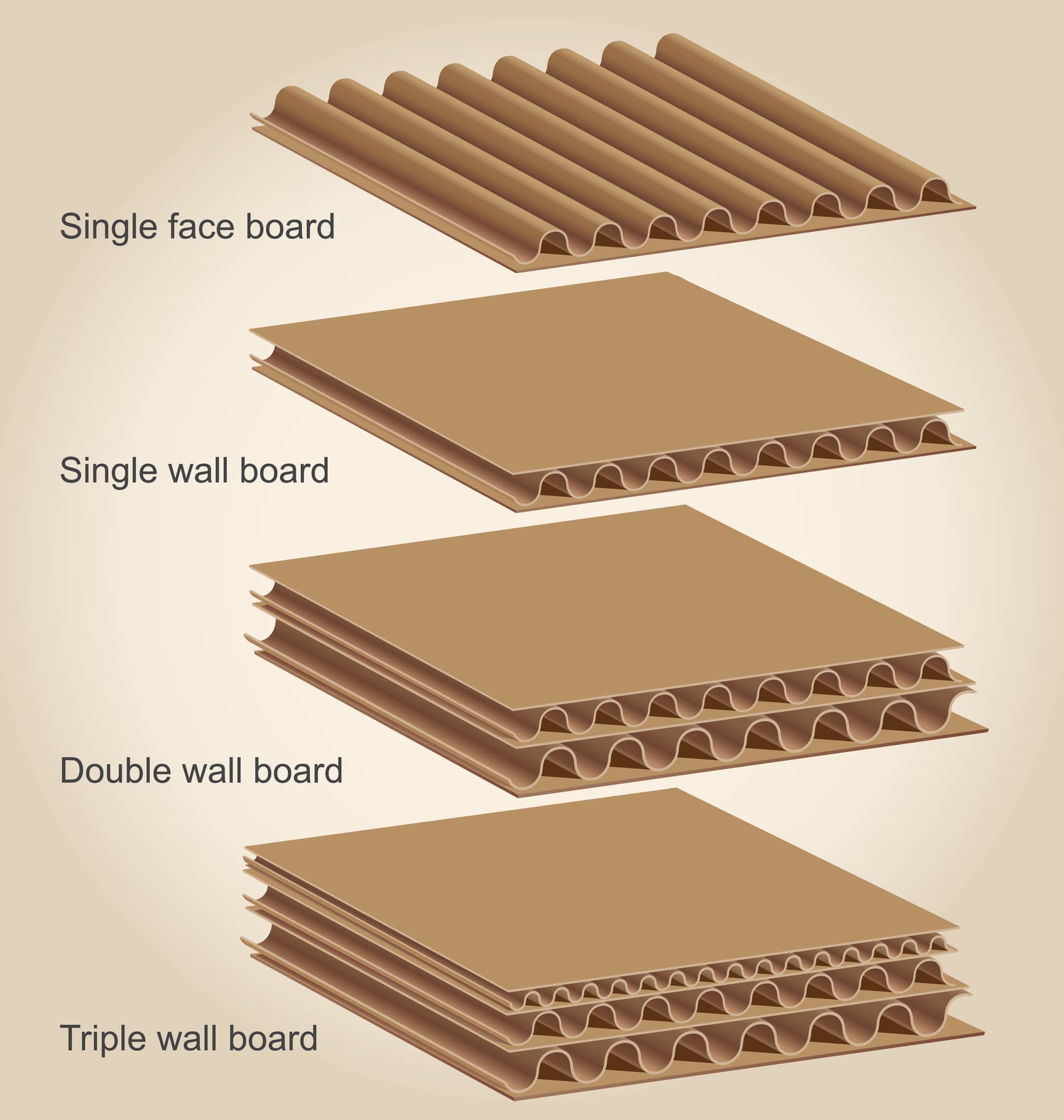

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of

As the world becomes more environmentally conscious, companies are looking for ways to reduce their impact on the planet. One of the ways that they

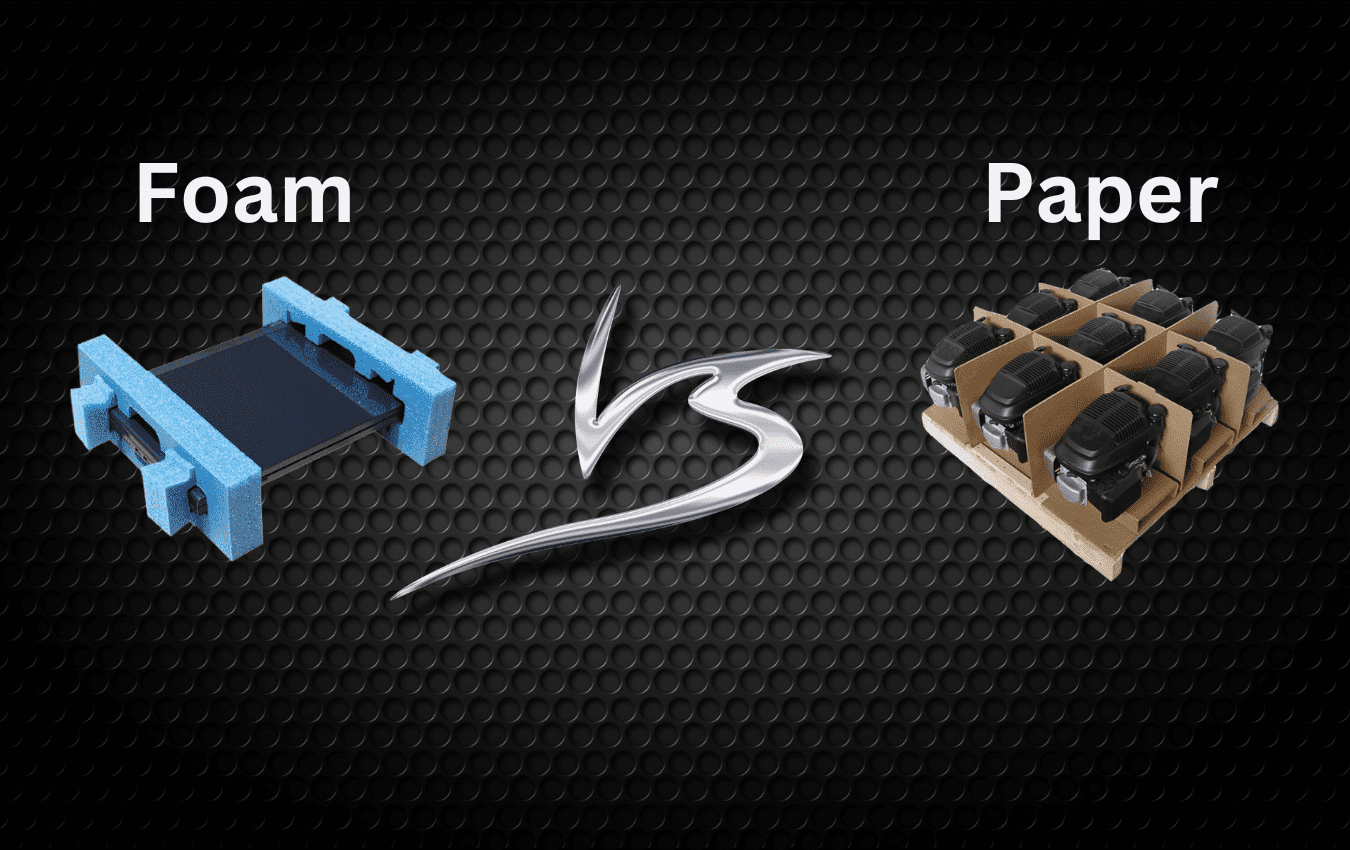

In the world of e-commerce and supply chain management, the need for reliable packaging materials cannot be overstated. From the careful encasing of fragile items

In today’s competitive business landscape, every company needs to utilize all potential avenues to get its brand and products noticed. One such avenue that often

When it comes to presenting your products, every detail matters. One aspect that often goes unnoticed but holds considerable significance is the packaging of the

In the rapidly expanding global marketplace, companies constantly strive to distinguish their products and safeguard them during transit. Custom packaging plays an essential role in

In today’s competitive market, businesses need to constantly look for ways to cut costs and increase efficiency to remain profitable. One area where businesses can

In our daily lives, we come across a plethora of pharmaceutical products, either in our personal capacity or via someone close to us. In this

Flexographic printing is a widely used printing method in the packaging industry that offers several advantages, including high efficiency, versatility, and cost-effectiveness. However, the sustainability

When it comes to shipping or storing fragile items, ensuring their safe arrival without any damage is of utmost importance. Fragile items such as glassware,

In the ever-competitive business world, effective product packaging has evolved beyond mere containers used to secure goods for transit. Today, it serves as a powerful

Corrugated box inserts are a key player in the world of packaging solutions. Not only do they secure and protect the products during transit, but

Point of purchase displays, also known as POP displays, are an essential marketing tool for businesses to showcase their products and attract customers. However, creating

Packaging plays a crucial role in marketing a product. The packaging material and design not only protect the product but also influence the customer’s purchasing

Custom packaging is the process of creating unique and personalized packaging materials tailored to the specific requirements of a product, brand, or business. In today’s

Flexible packaging is a dynamic and growing market that has revolutionized the packaging industry. From snack foods to pharmaceuticals, flexible packaging offers lightweight, cost-effective, and