Home » Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

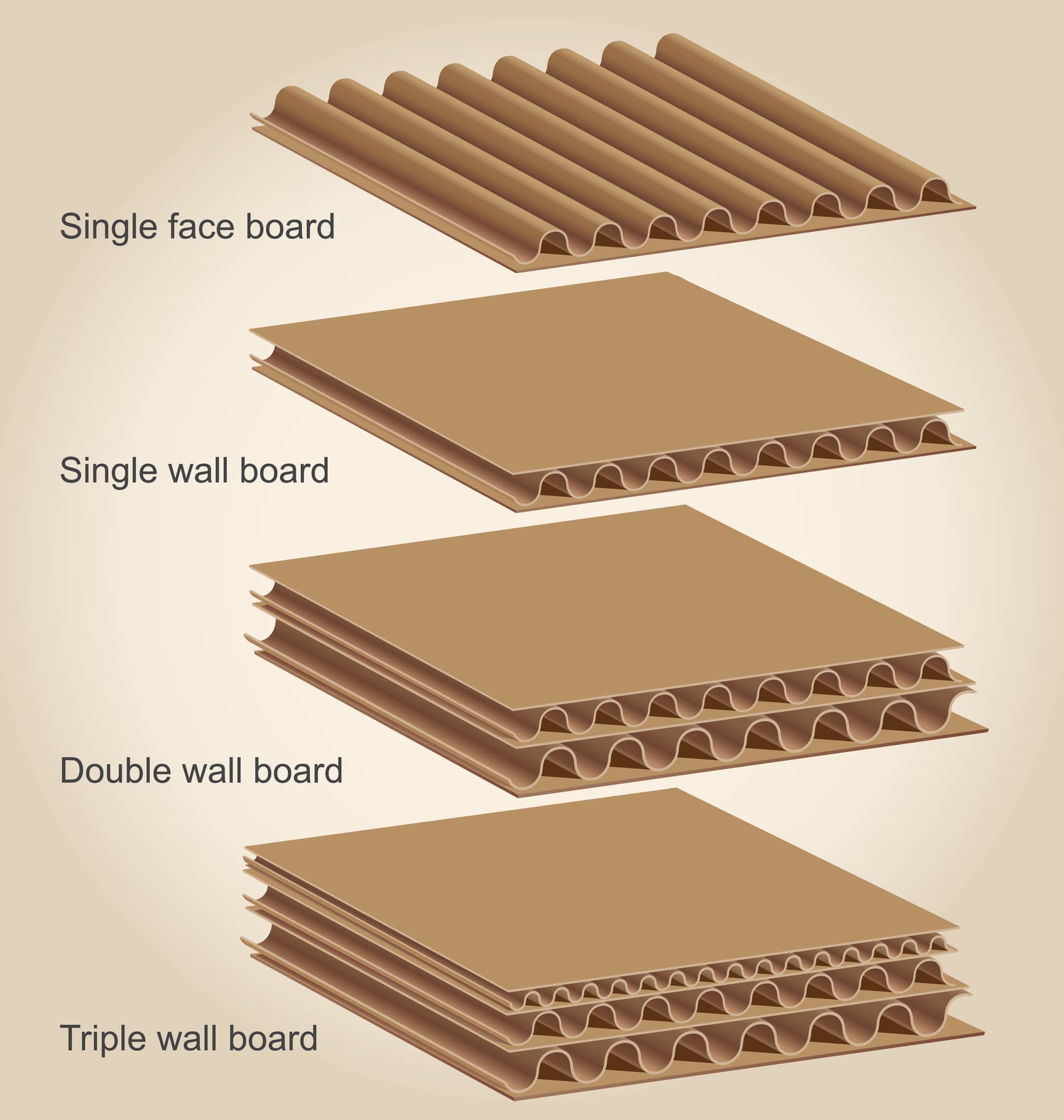

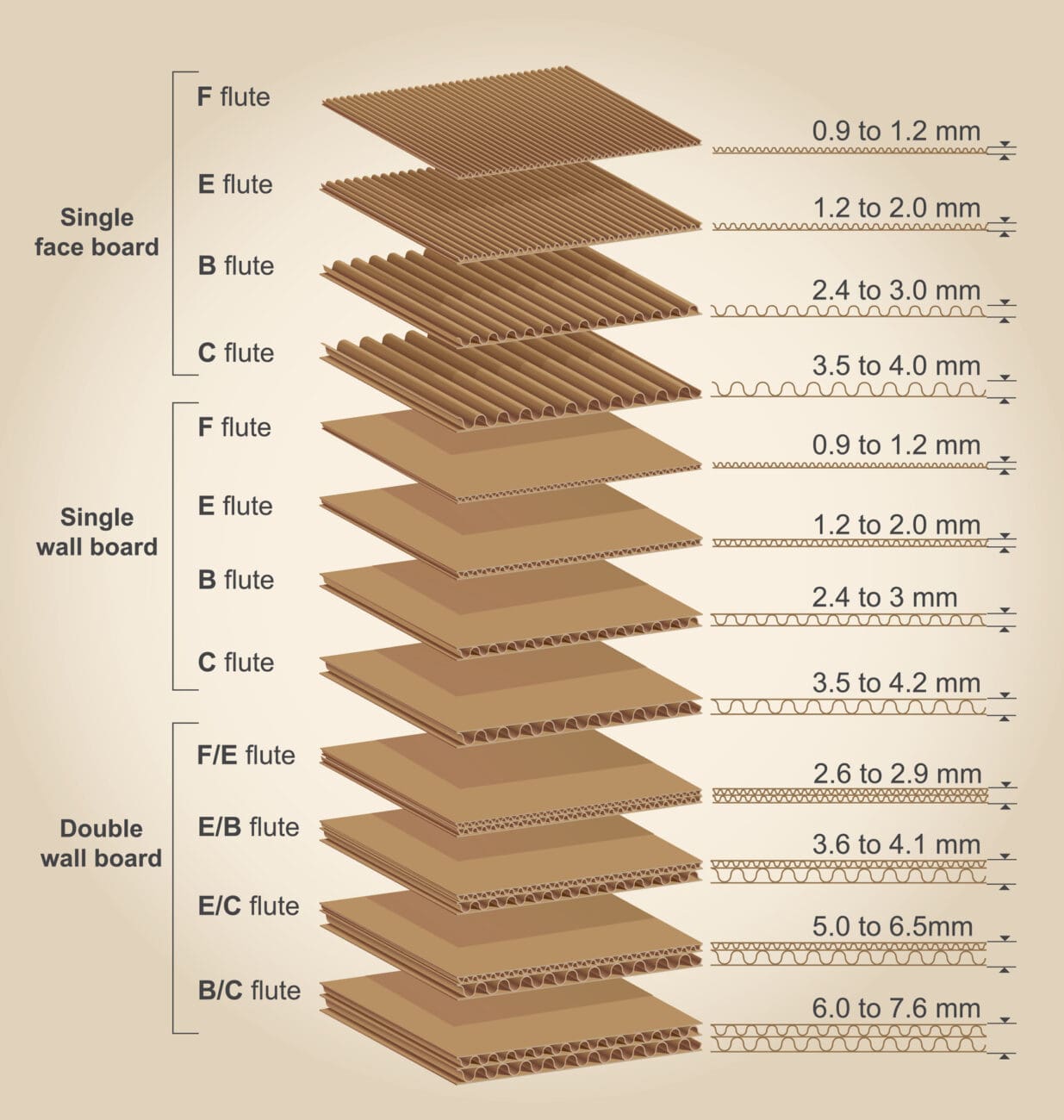

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of a fluted sheet sandwiched between two flat sheets of paperboard. This type of board is available in different grades and thicknesses, and is classified into three types: single wall, double wall, and triple wall.

Single Wall Board

Single wall board is the most basic type of corrugated board, consisting of a single layer of fluted paperboard sandwiched between two flat sheets of paperboard. Single wall board is available in different grades and thicknesses, and is ideal for packaging applications that require a lightweight and cost-effective solution. It is often used for shipping and storing small items such as books, clothing, and electronics, as well as for product displays, storage bins, and mailers.

Double Wall Board

Double wall board is made by combining two layers of fluted paperboard with three flat sheets of paperboard. This type of board is thicker and more durable than single wall board, and is ideal for packaging applications that require extra protection and strength. It is often used for shipping and storing heavier items such as appliances, furniture, and automotive parts, as well as for industrial packaging, retail displays, and point-of-purchase displays.

Triple Wall Board

Triple wall board is the thickest and strongest type of corrugated board, made by combining three layers of fluted paperboard with four flat sheets of paperboard. This type of board is ideal for packaging applications that require maximum protection and strength. It is often used for shipping and storing extremely heavy items such as machinery, equipment, and bulk products, as well as for pallet boxes, crates, and reusable containers.

Choosing the Right Type of Board

When choosing the type of board for packaging, factors such as the weight and size of the product being shipped or stored, the shipping and handling conditions, and the intended use of the packaging should be considered. Single wall board is suitable for smaller and lighter items, while double wall or triple wall board is necessary for heavier and larger items that require extra protection and strength. For products that require maximum protection against shock, vibration, and impact, triple wall board is the best choice.

Summary: Corrugated Boards Explained

In conclusion, corrugated board is a versatile packaging material that offers various options for different packaging needs. By selecting the right type of board, businesses can ensure that their products are properly protected during transportation and storage.

If you are interested in any stock or custom corrugated packaging, then partner with Brown Packaging today to get started.

Why Co-Packaging Becomes Critical During the Holidays As the holiday season approaches, packaging teams are under pressure to deliver high volumes of promotional sets, combo

Holiday demand starts long before December. So should your packaging. For B2B and D2C brands alike, Q4 is the most critical—and most chaotic—shipping window of

The Challenge of Multi-SKU Holiday Programs During the holiday season, brands often shift from selling single products to curated sets, bundled assortments, and promotional kits—each

Rigid boxes are the gold standard of premium packaging. Whether used for cosmetics, electronics, fashion, or high-end subscription kits, rigid boxes do more than protect

Understanding One-Piece FOL and Three-Piece Bike Shipping Boxes Choosing the right box style is essential when shipping bicycles—especially for brands, manufacturers, and distributors focused on

Corrugated boxes are essential to shipping, retail, and e-commerce—but when you introduce custom printing, the stakes (and the opportunities) rise. Print isn’t just about looks—it’s

Home » Understanding Corrugated Board: Single Wall, Double Wall, and Triple Wall Packaging

The world of packaging design is rich with innovative solutions that cater to various product needs. Among these, Roll End Tuck Tops (RETT), Cherry Locks,

Packaging plays a crucial role in protecting products during transportation and handling. However, not all packaging materials, such as corrugated are created equal, and choosing

A Full Overlap (FOL) box is a type of corrugated shipping box where the flaps fully overlap each other when closed, providing additional strength and