Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In today’s competitive market, luxury packaging isn’t just about presenting a product; it’s about crafting an experience. The most successful luxury brands understand that their

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and

Launching a product or redesigning packaging can be a significant investment. To minimize risk and gather actionable insights, small packaging runs are a smart way

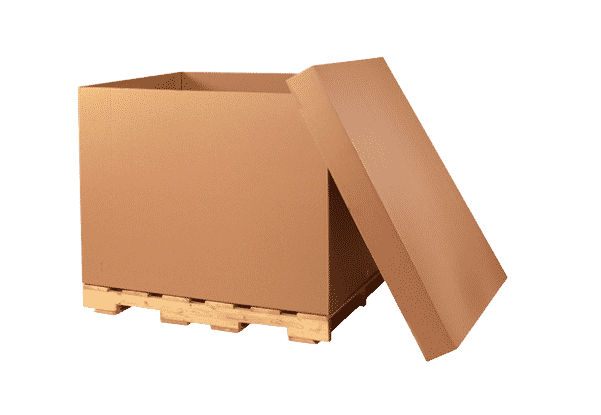

Gaylord containers are large, sturdy boxes used primarily for shipping, storing, and handling bulk materials. Often utilized in industries like manufacturing, agriculture, and retail, these

When choosing corrugated board for packaging, print quality is often a critical consideration. Two common board types—ECT (Edge Crush Test) board and Bursting Test board,

Why Packaging Strategy Matters Packaging is more than just a protective layer—it plays a vital role in branding, marketing, and customer experience. One of the

When selecting foam materials for packaging, polyethylene foam (PE) and polyurethane foam (PU) are two popular choices. While both offer protection and cushioning, their properties,

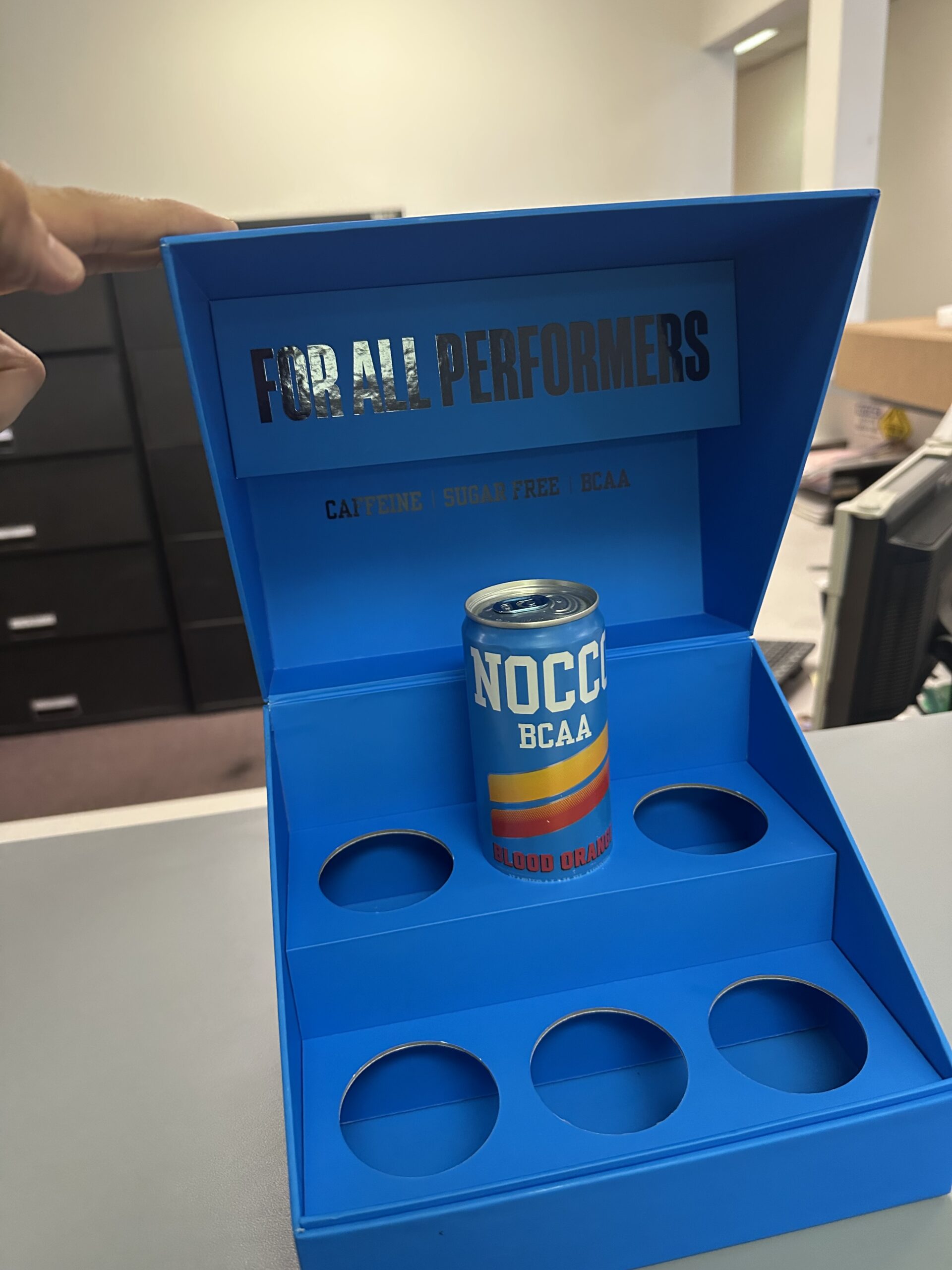

When NOCCO needed a high-end packaging solution for their influencer and investor campaign, they faced a major challenge—tight deadlines, no initial design, and the need

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized

A study published in September 2024 in Frontiers in Toxicology has identified 189 chemicals present in food packaging materials that are potential or confirmed mammary carcinogens,

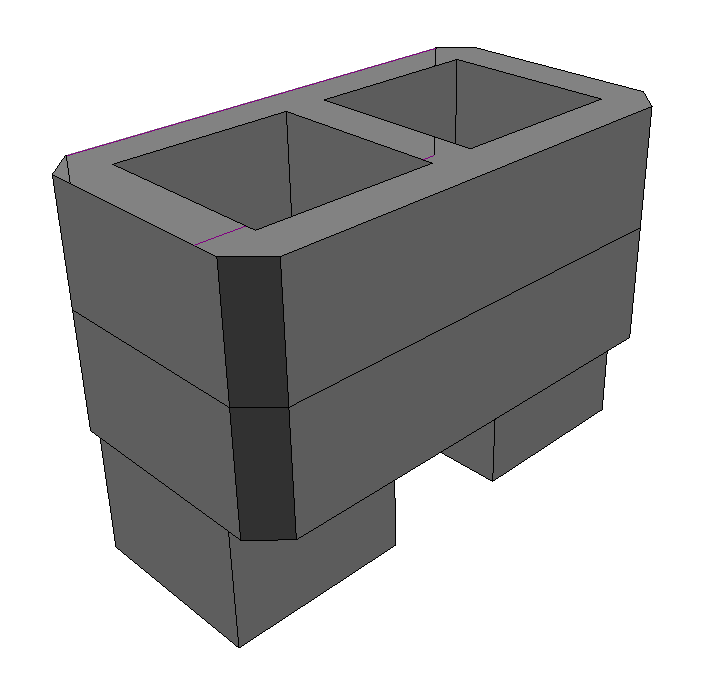

When working with thick foam materials in the packaging industry, it’s important to be aware of the natural outcomes of the die-cutting process—one of the

Mailing tubes have long been a popular choice for shipping and storing various items, from posters and blueprints to documents and delicate artworks. While they

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression.

Corrugated boxes are strong because of their unique construction, which features a fluted corrugated sheet sandwiched between two flat linerboards. This design creates a robust

Corrugated boxes are highly effective for a wide range of packaging needs, providing superior protection, durability, and versatility. Their unique construction allows them to withstand

Point of Purchase (POP) displays are a dynamic marketing tool used to engage customers and boost sales at the point of decision-making. Whether you’re a

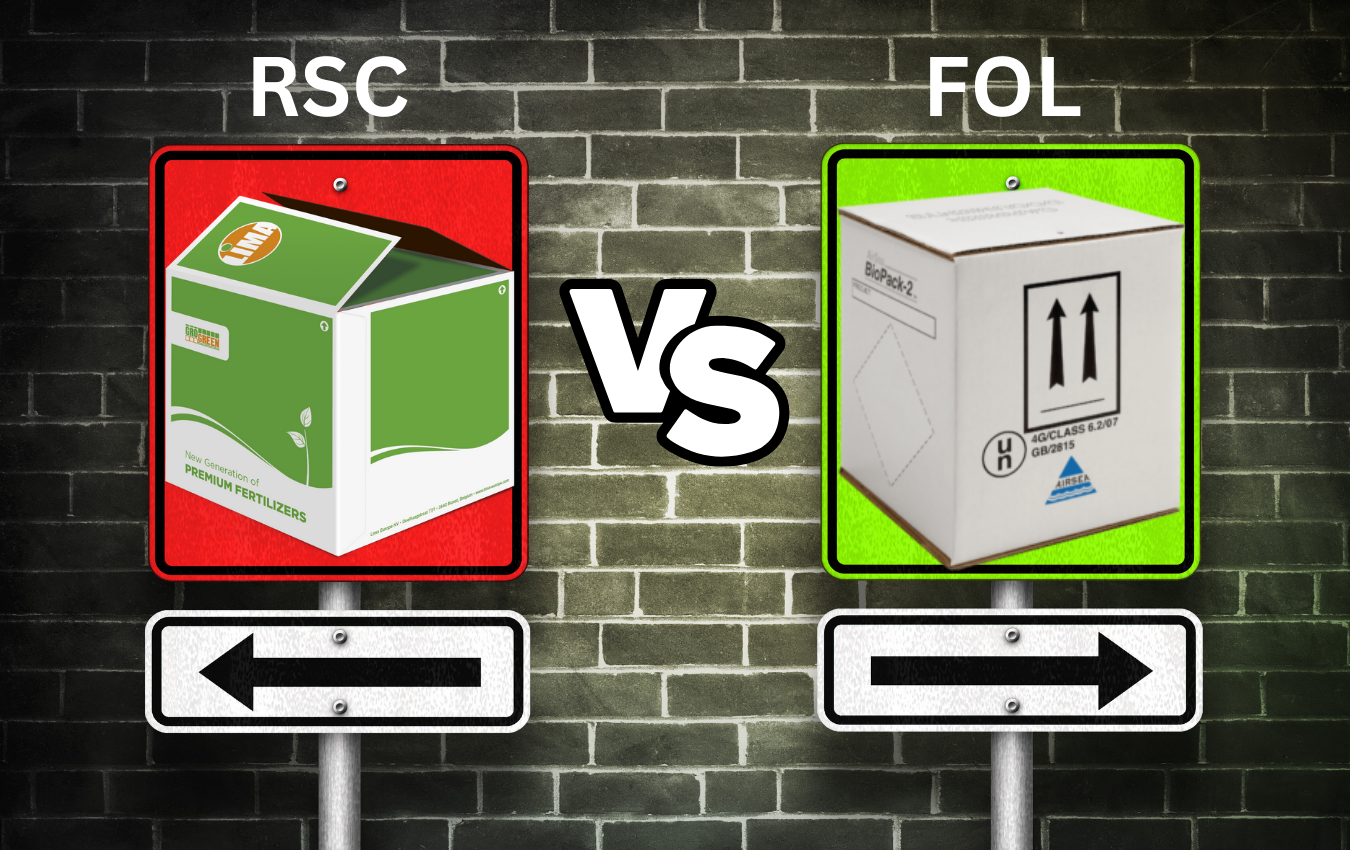

Full-Overlap (FOL) boxes are renowned for their structural integrity and robust design, making them a popular choice for packaging products that require extra protection during

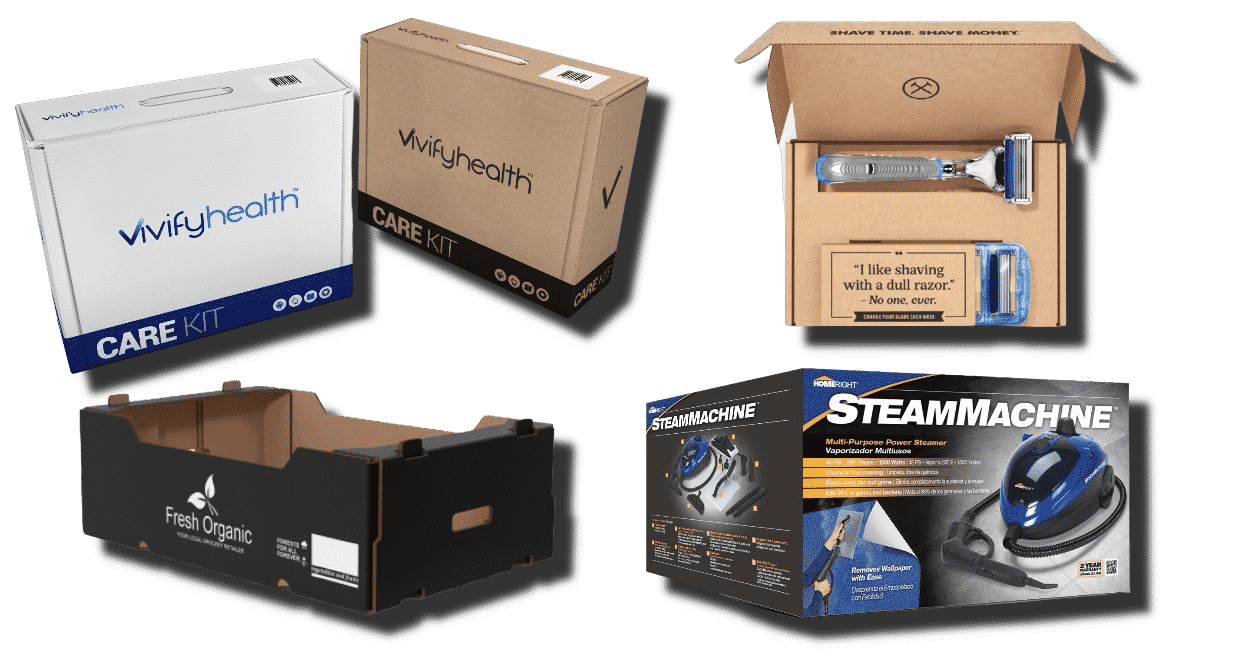

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box

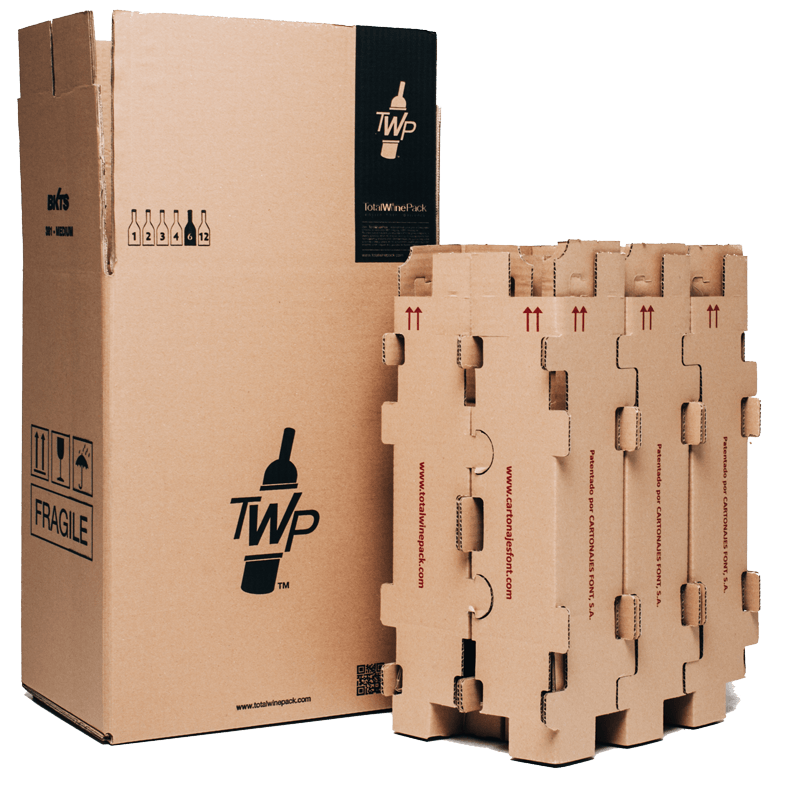

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to

As a small business owner, bringing your product to retail is a significant milestone, and the packaging plays a crucial role in making a lasting

In the competitive world of retail, effective packaging can make all the difference. If your product finds itself on the bottom shelf, it’s essential to