Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

Packaging for toddler toys is a unique segment that requires a thoughtful approach, balancing safety, engagement, and often, an educational aspect. This blog post explores

Packaging plays a pivotal role in the world of snacks, influencing everything from freshness and shelf life to branding and consumer appeal. With a multitude

In the packaging industry, achieving the perfect balance between ensuring product safety and optimizing space is a complex yet vital goal. This blog post explores

For industries seeking efficient solutions for material storage and transportation, corrugated gaylord boxes have emerged as a viable alternative to plastic totes and super sacks.

Packaging is a critical component of our daily lives, serving a dual purpose of protecting products and conveying vital information to consumers. In the wake

Shipping goods can be a stressful experience, especially when you’re worried about their safety during transit. Corrugated boxes, due to their durable and versatile nature,

In the world of packaging, roll stock, also referred to as candy wrappers or snack wrappers, is a versatile and essential component. It refers to

Packaging design is a crucial aspect of any product’s marketing strategy. It serves as a visual ambassador for your brand and plays a pivotal role

Packaging is an essential aspect of the modern supply chain, serving as a protective shield for products, preserving their quality, and enhancing their marketability. Among

In the world of logistics and supply chain management, the cost of shipping plays a pivotal role in determining a company’s profitability. While factors like

For those uninitiated in the finer points of storage and organization, corrugated bin boxes might sound like an odd focal point. However, for hardware stores,

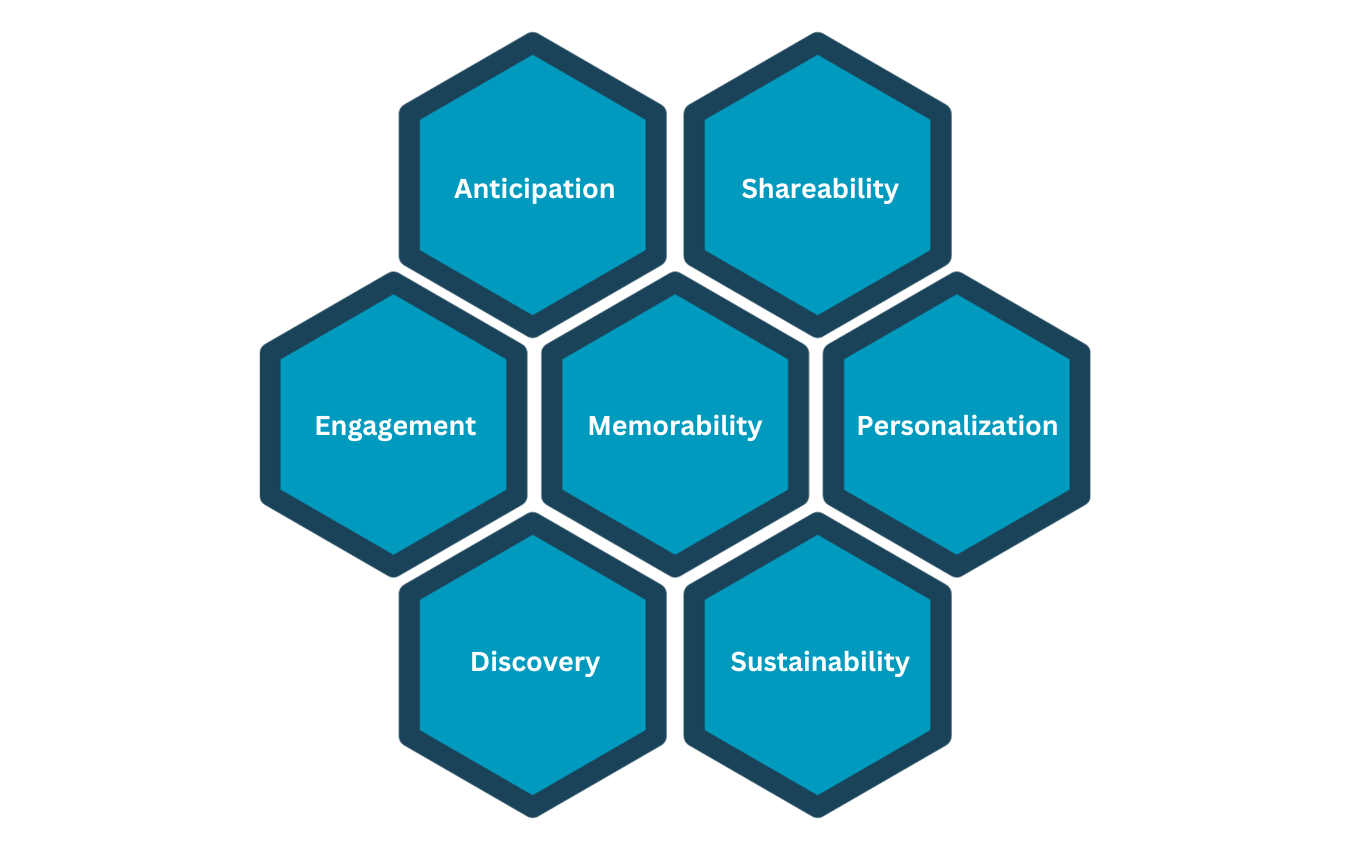

In today’s competitive marketplace, it’s not enough for a product to be high-quality; it must also provide an exceptional experience from the moment it arrives

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But

For retailers and suppliers in the cycling industry, your bicycles are more than just products—they represent a passion for cycling and a commitment to quality.

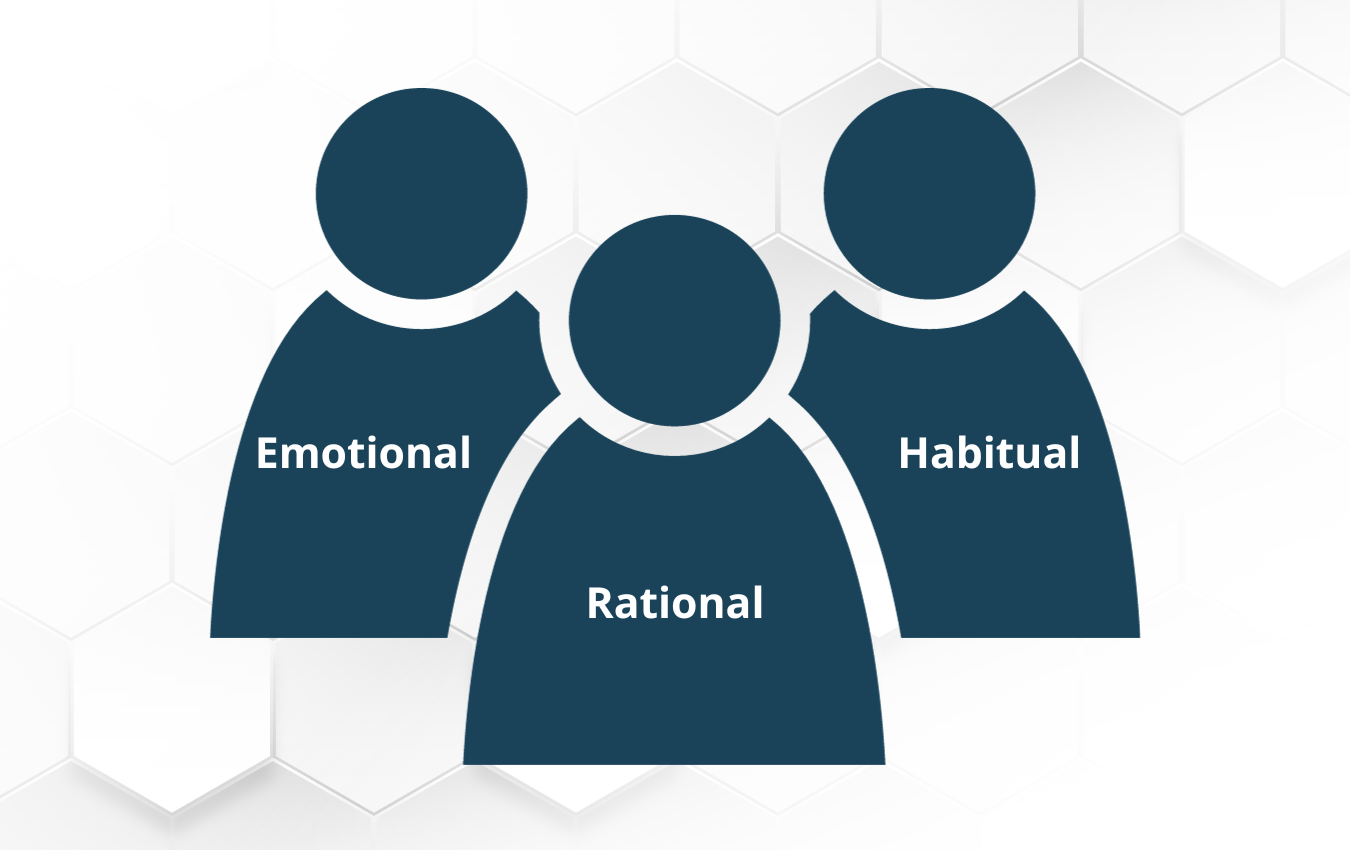

In a fiercely competitive retail landscape, brands strive to ensure their products stand out on the shelves. And one powerful tool they leverage is packaging.

In the dynamic world of marketing, packaging plays a central role in shaping consumer perceptions and influencing purchasing decisions. Custom packaging offers a unique opportunity

In the realm of marketing, storytelling has evolved into a potent tool for brands to forge meaningful connections with consumers. Beyond the mere sale of

When it comes to delivering the beloved and delicious treat that is pizza, the packaging plays a crucial role. The right pizza box not only

In the dynamic world of marketing, packaging isn’t just a protective shell for your product; it’s a powerful tool for capturing the hearts and minds

The flexible packaging industry is experiencing a significant evolution as it leans into more sustainable practices. Amid growing environmental concerns, there’s a strong movement within

In the competitive business landscape of today, custom packaging has emerged as a powerful tool to not only protect products but also make a lasting