Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

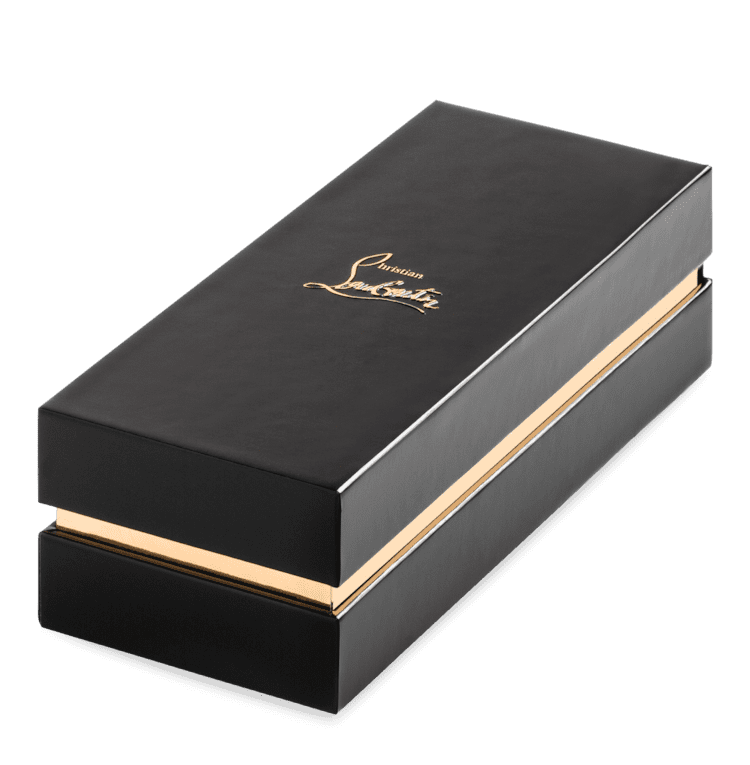

Rigid boxes, known for their durability and premium appearance, are a popular choice for packaging high-end products. However, the perception of being expensive can deter

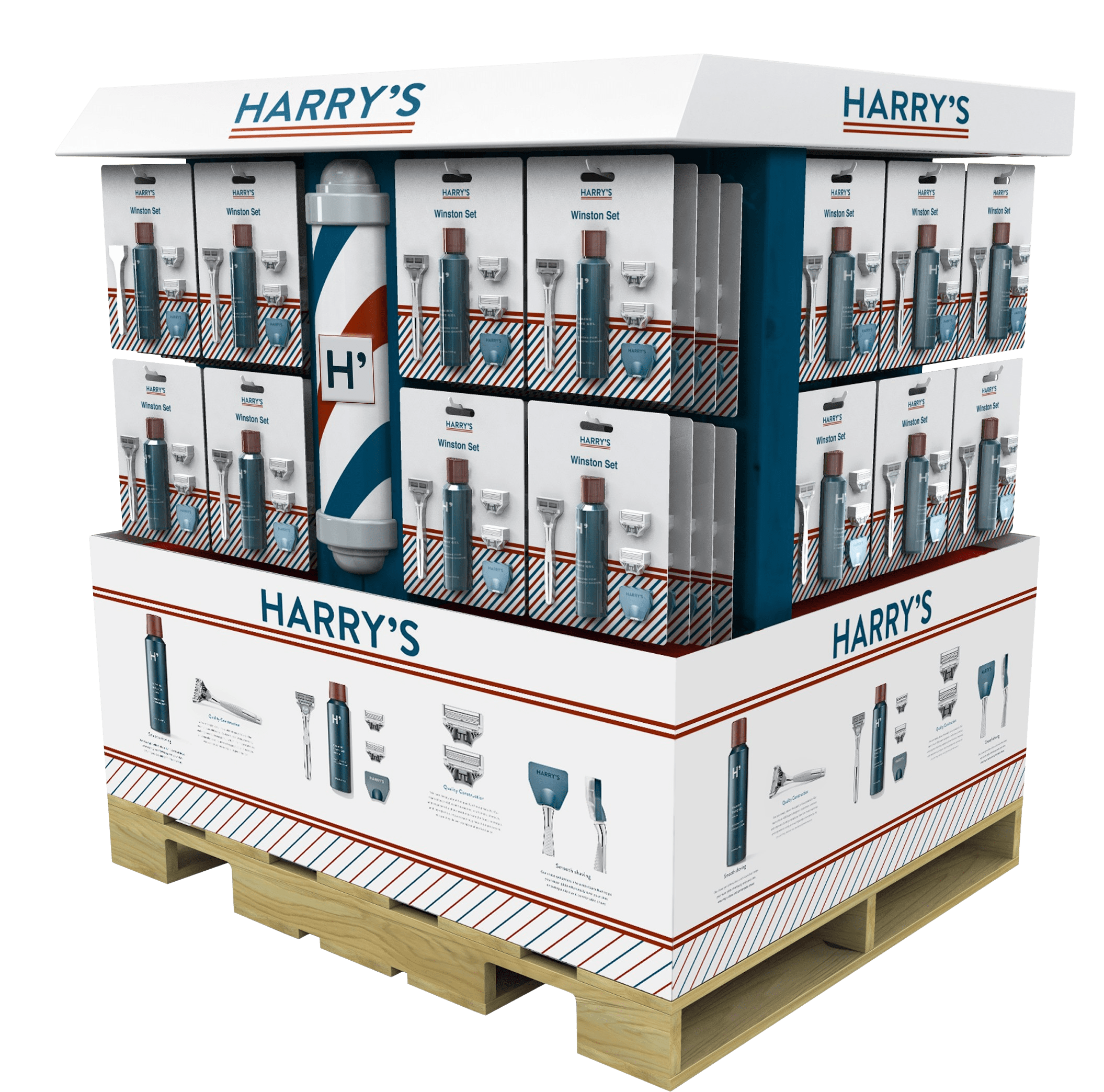

Creating a successful Point of Purchase (POP) display involves thorough research and careful planning. This crucial second step in the development of a POP display

In e-commerce, the customer experience doesn’t end with the sale—it often continues through the returns process. With many customers expecting hassle-free returns, especially during the

The holiday season is one of the busiest and most critical times for e-commerce businesses. With the influx of online shopping, it’s essential to create

For retail brands, Point of Purchase (POP) displays are crucial for maximizing product visibility and driving sales. Ensuring that these displays are retail-ready is key

In the realm of packaging solutions, roll end tuck top (RETT) boxes are hailed for their durability and versatile design. Yet, among their many attributes,

Point of Purchase (POP) displays are a key element in influencing consumer decisions at the critical moment before purchase. The effectiveness of these displays can

As environmental concerns continue to dominate consumer and regulatory conversations, the packaging industry is responding with innovative, eco-friendly solutions. In 2025, sustainable packaging will not

As we approach 2025, the packaging industry continues to evolve in response to environmental pressures, consumer demands, and technological advancements. Businesses are increasingly focusing on

In retail, the ease with which customers can interact with products directly influences their purchasing decisions. Point of Purchase (POP) displays designed with accessibility in

In the world of packaging, there’s a rising star that has gained immense popularity – the Roll End Tuck Top (RETT) box. Its versatility, durability,

Creating impactful promotional messaging for Point of Purchase (POP) displays is vital for capturing customer interest and driving sales. This guide explores essential strategies for

Bundle packaging is a versatile marketing strategy that can be applied in various ways to enhance product offerings and increase customer satisfaction. In this blog,

In an increasingly competitive marketplace, the role of packaging extends beyond the first point of sale – it’s a vital tool in fostering customer loyalty

In today’s competitive business landscape, packaging plays a crucial role in attracting customers and setting your products apart from the competition. While larger corporations often

When it comes to marketing and selling products, presentation matters. Bundle packaging is a clever and effective strategy that many businesses use to enhance their

In the world of retail and e-commerce, packaging isn’t just about protecting products; it’s an essential part of the overall customer experience. One effective strategy

Oxygen and air exposure can adversely affect the quality, shelf life, and safety of your products. To ensure the integrity of your products and packaging,

When it comes to packaging liquids and semi-liquids, two popular options are spout pouches and traditional bottle packaging. Both have their advantages and disadvantages, making

Packaging plays a crucial role in product presentation, preservation, and sustainability. While packaging regulations across the United States generally adhere to federal guidelines, California stands

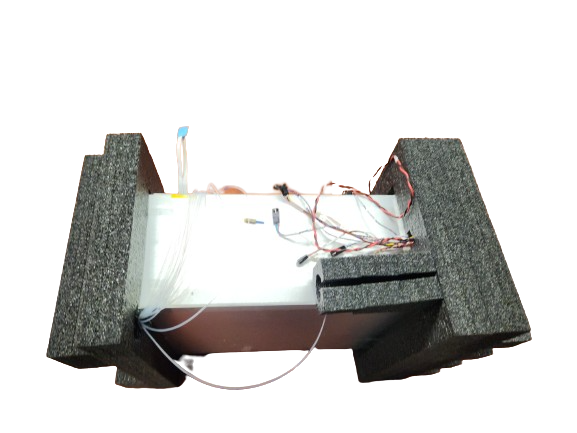

In the realm of packaging materials, the choice between polyethylene (PE) and laminated polyethylene foam can significantly impact the effectiveness and functionality of your packaging