Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

Effective packaging plays a crucial role in product presentation and protection across various industries. Among the many packaging options available, blister packaging stands out as

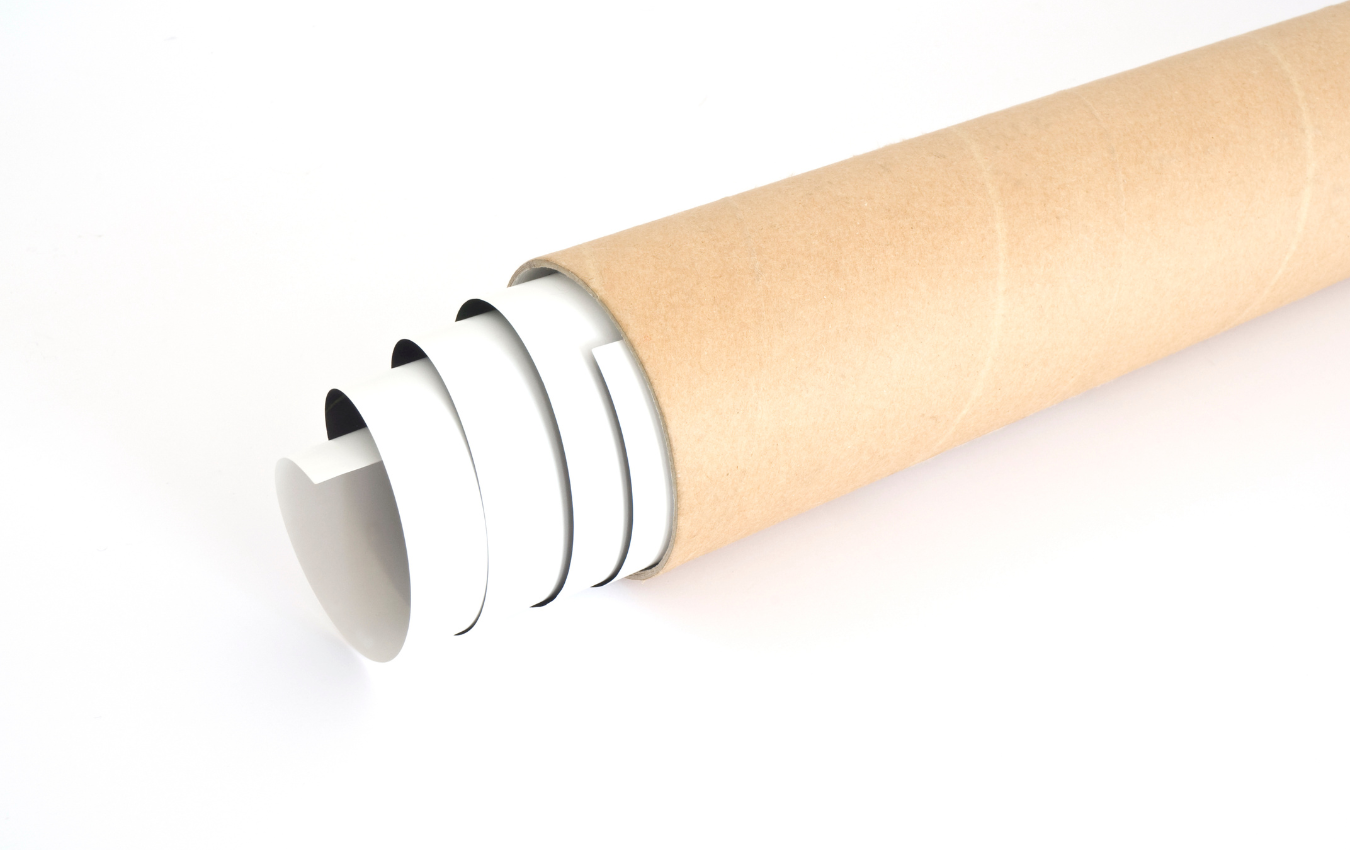

Mailing tubes are a popular choice for safely shipping and storing various items, such as posters, blueprints, and documents. While these tubes offer excellent protection

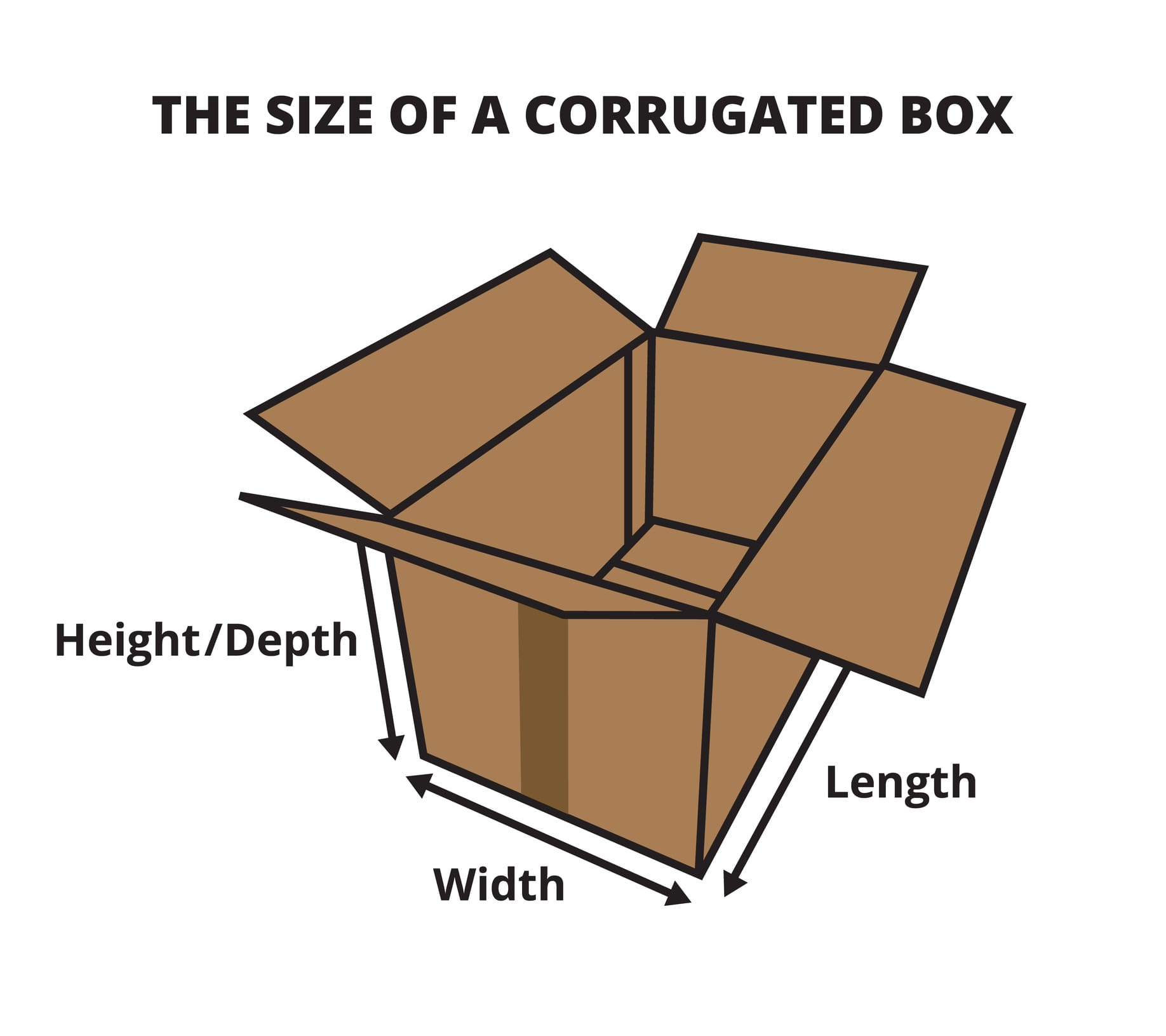

Whether storing household items, packing for a move, or packaging products for shipping, we often take corrugated boxes for granted. They offer strength, durability, and

Straight Tuck End (STE) folding cartons are a popular and widely used type of packaging for consumer goods such as food, beverage, cosmetics, and household

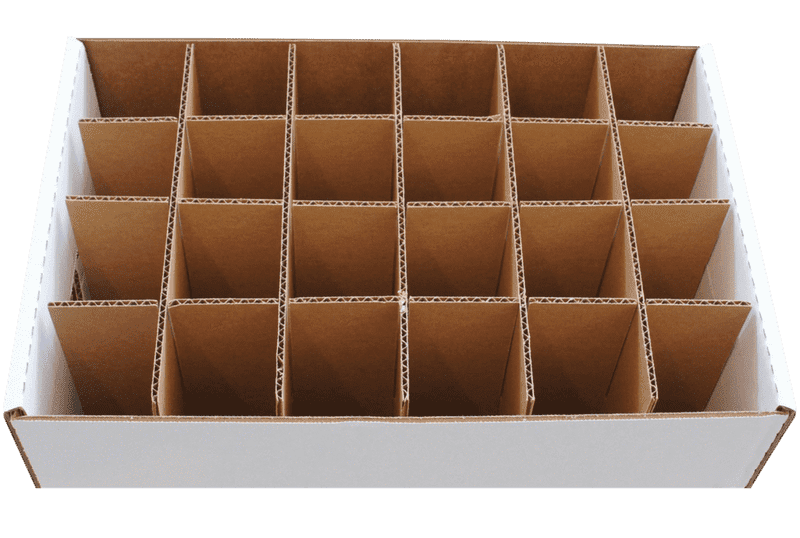

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard,

In today’s digital age, online packaging companies offer the convenience of DIY packaging solutions. However, the allure of DIY packaging can mask significant challenges. In

In the world of e-commerce, packaging is much more than just protection for your products. It has evolved into a vital marketing asset that helps

The longevity of corrugated boxes, a question frequently asked by businesses and consumers alike, hinges on several key factors, including their construction, material quality, and

A Point of Purchase (POP) display is a powerful marketing tool used by retailers and brands to attract customers’ attention, showcase products, and boost sales

Yes, a corrugated box is an excellent choice for shipping due to its strong, durable nature and its ability to protect contents from damage during

Saving on the purchase of corrugated boxes involves strategic planning and smart sourcing to ensure you get the best value without compromising on quality. By

In October 2024, California made a groundbreaking move by banning “sell by” dates on food products. This legislation aims to reduce consumer confusion, minimize food

The weight a corrugated box can hold depends on factors such as box construction, material grade, flute size, and box dimensions. Corrugated boxes are designed

Structurally designing your corrugated box involves understanding the specific requirements of your product and applying principles of material science and engineering to ensure optimal protection,

Roll stock flow wrap packaging is a versatile and efficient method used in the food and packaging industry to package a wide variety of products.

As businesses prepare for a new fiscal year, evaluating packaging needs becomes a crucial part of the planning process. Effective packaging not only protects your

Effective packaging serves multiple purposes, including protecting products from dust, moisture, and tampering. These elements can compromise product quality, safety, and integrity during storage and

There’s a common saying in the marketing world: “It’s not what you sell that matters as much as how you sell it.” While the quality

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right

Tariffs can create significant challenges for packaging buyers, affecting costs, supply chains, and sourcing strategies. While tariffs are designed to promote domestic production, they often