Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

Why Board Grade Selection Matters In today’s volatile supply chain environment, packaging failures aren’t just a nuisance—they’re a liability. Damage in transit, product returns, and

Why Holiday Fulfillment Demands Precision The holiday season introduces a unique set of pressures across the packaging and supply chain landscape—especially for businesses managing kitting,

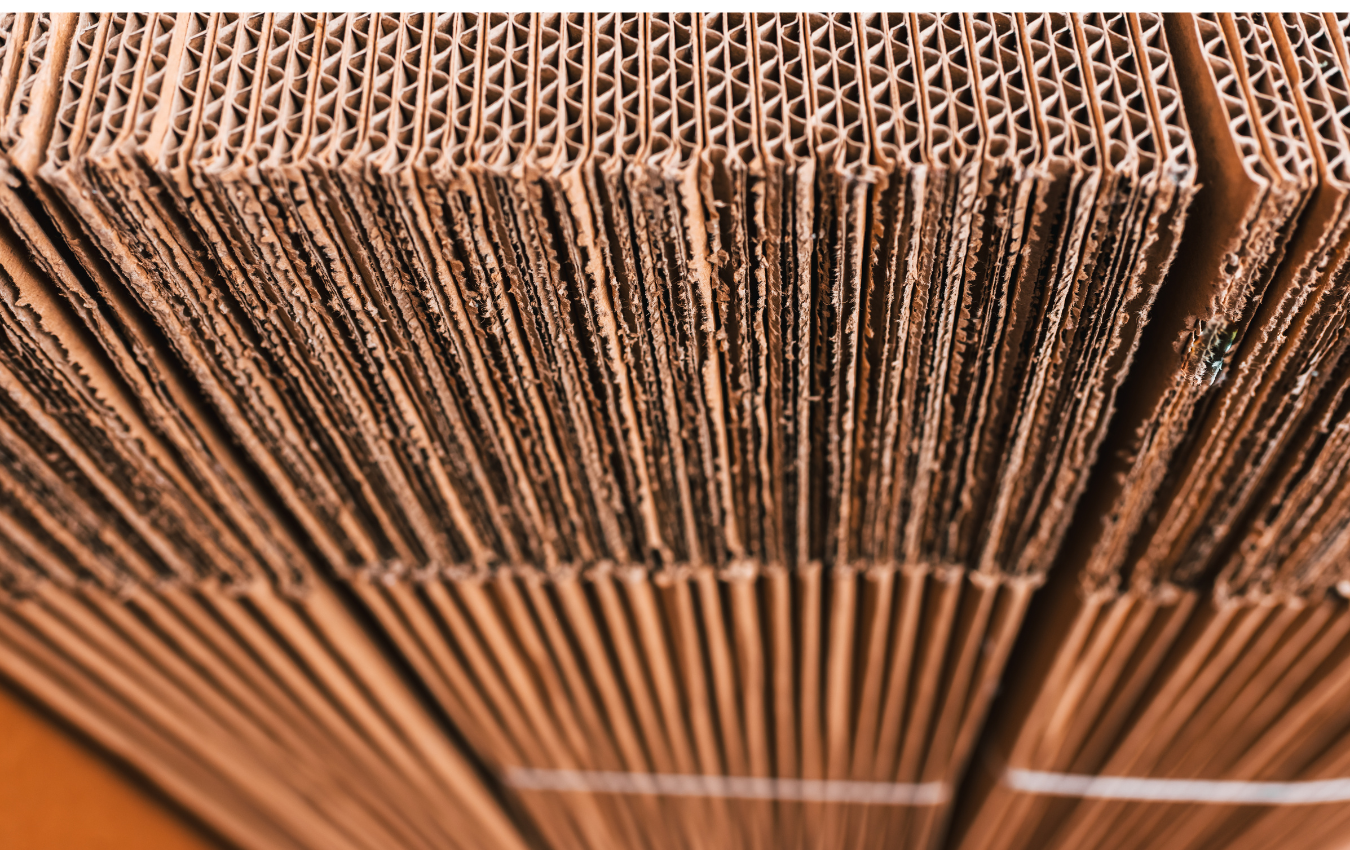

Why Custom Corrugated Boxes Remain a 2026 Essential Custom corrugated boxes continue to be the most relied-on packaging solution for industries ranging from industrial manufacturing

Why Co-Packaging Becomes Critical During the Holidays As the holiday season approaches, packaging teams are under pressure to deliver high volumes of promotional sets, combo

Holiday demand starts long before December. So should your packaging. For B2B and D2C brands alike, Q4 is the most critical—and most chaotic—shipping window of

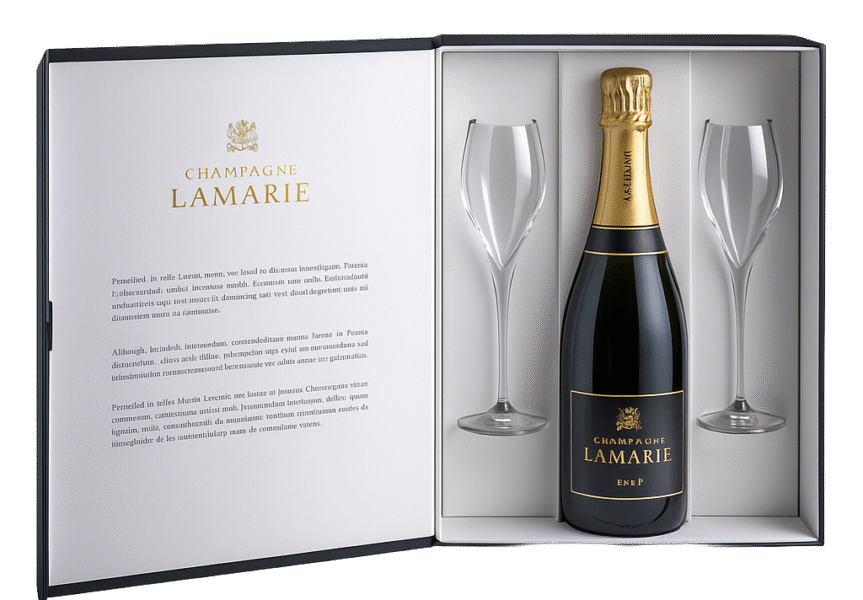

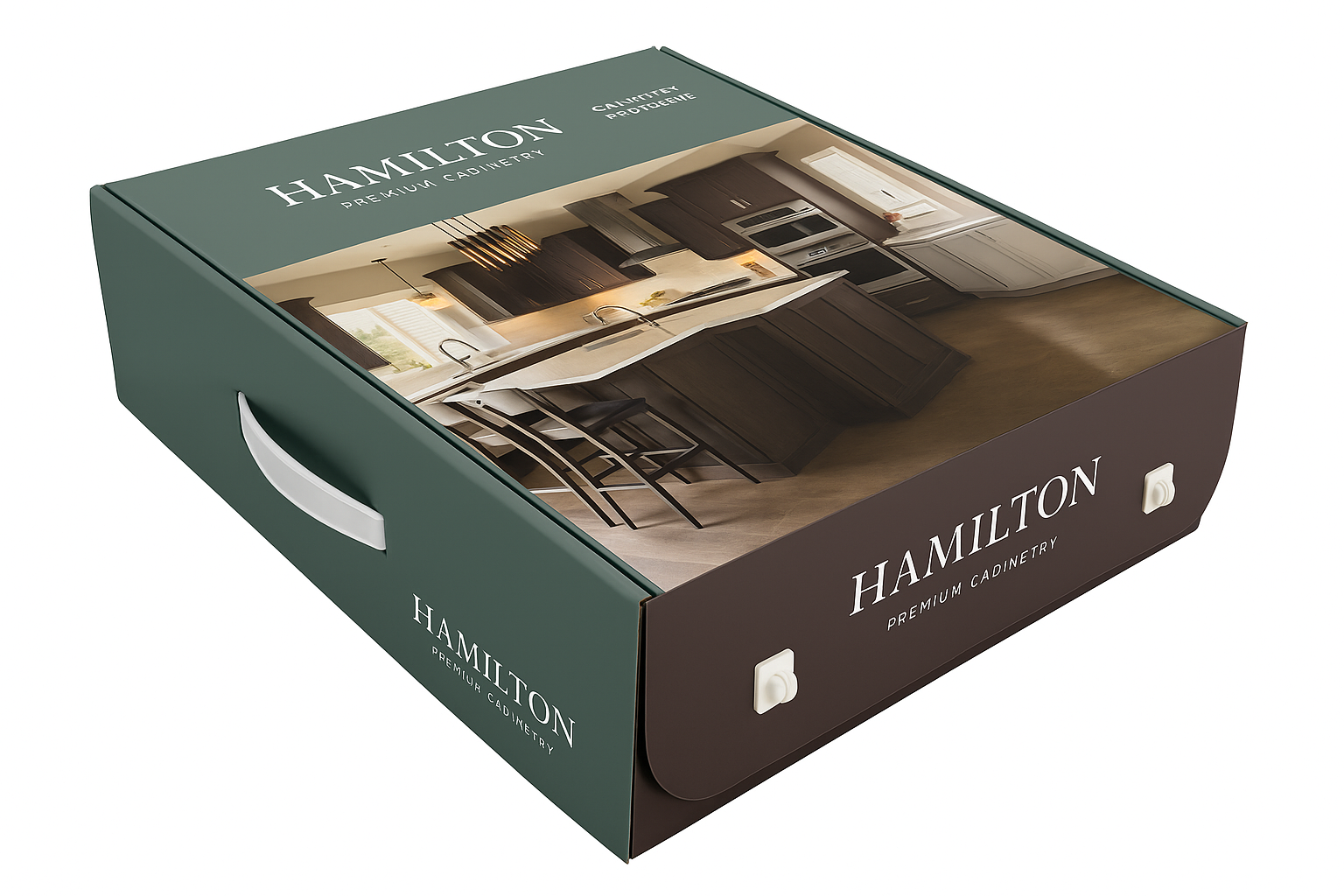

The Challenge of Multi-SKU Holiday Programs During the holiday season, brands often shift from selling single products to curated sets, bundled assortments, and promotional kits—each

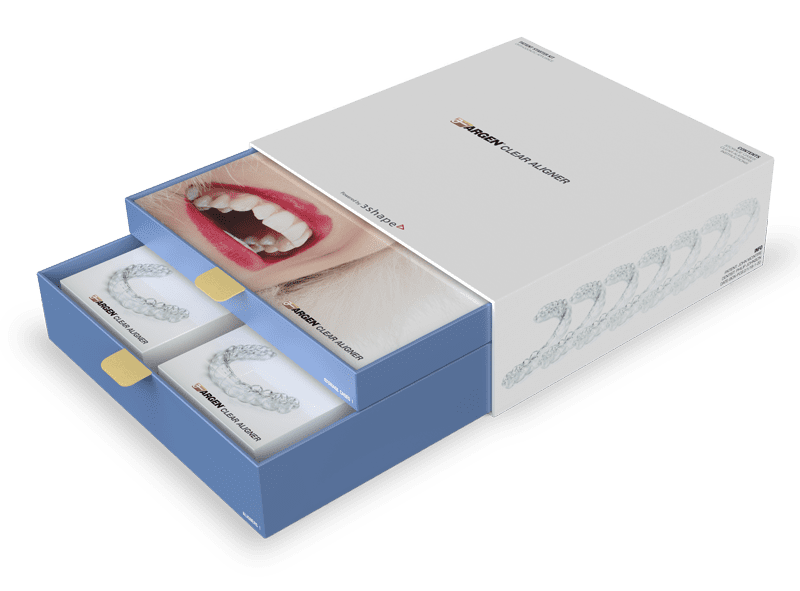

Rigid boxes are the gold standard of premium packaging. Whether used for cosmetics, electronics, fashion, or high-end subscription kits, rigid boxes do more than protect

Understanding One-Piece FOL and Three-Piece Bike Shipping Boxes Choosing the right box style is essential when shipping bicycles—especially for brands, manufacturers, and distributors focused on

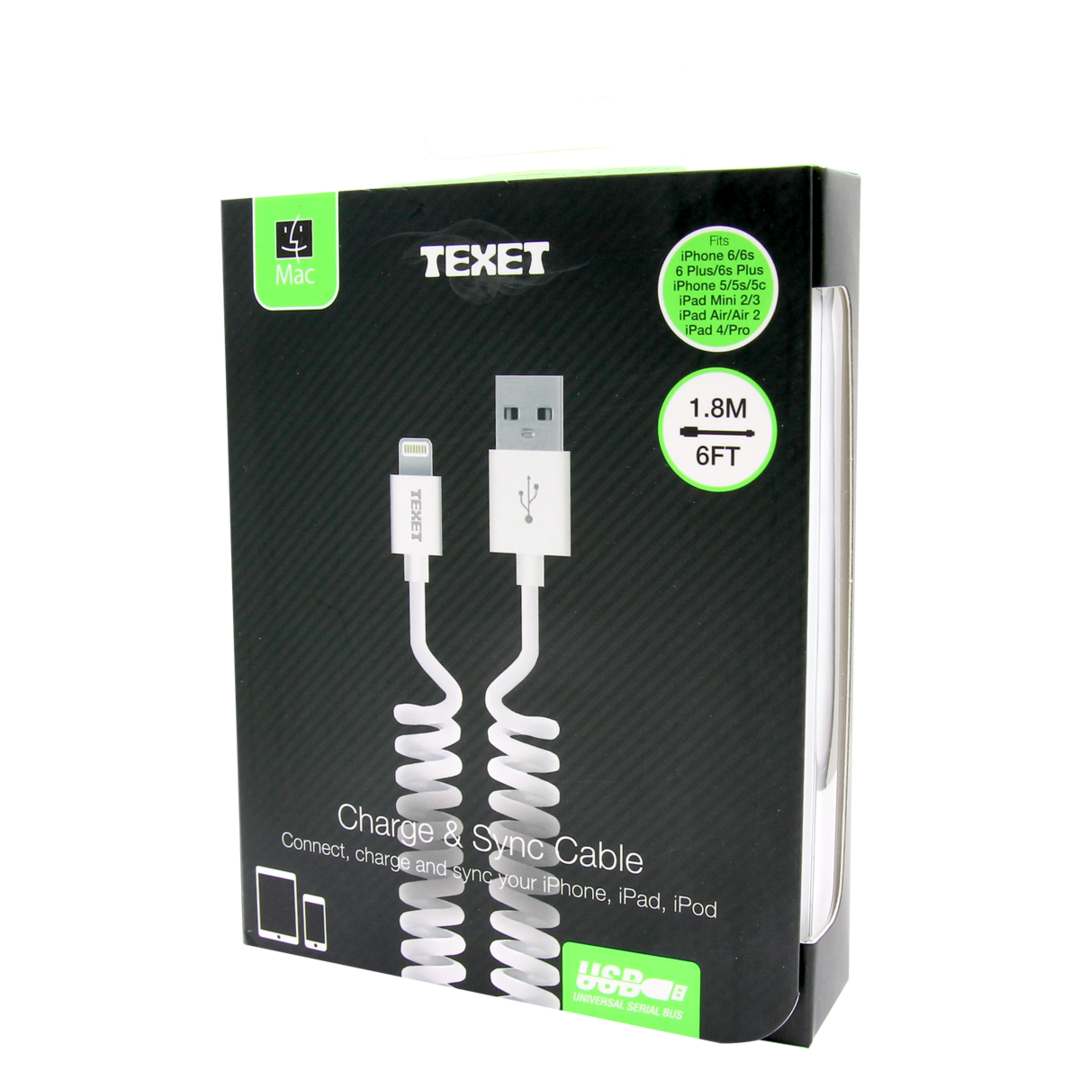

Corrugated boxes are essential to shipping, retail, and e-commerce—but when you introduce custom printing, the stakes (and the opportunities) rise. Print isn’t just about looks—it’s

When it comes to shipping bikes, selecting the right type of corrugated box is essential to ensure product protection, ease of handling, and cost efficiency.

Before committing to a full production run, businesses often receive packaging samples to evaluate fit, functionality, print quality, and overall design. Whether it’s a digital

Choosing the right corrugated box size is crucial for product protection, shipping efficiency, and cost savings. Whether you’re packing a single item or multiple products,

Medical device packaging plays a crucial role in protecting products, ensuring sterility, and enhancing user confidence. Beyond just functionality, packaging influences customer perception, which can

In 2025, small businesses must be more strategic than ever when it comes to packaging. With rising eCommerce competition, increasing material costs, and evolving consumer

For large businesses and corporations, packaging is more than just a protective shell—it’s an integral part of brand identity, supply chain efficiency, and consumer experience.

Folding cartons are a retail packaging staple—used across food, cosmetics, health, and consumer goods for their lightweight, customizable, and cost-effective structure. But not all folding

If you’re in the auto parts industry, you already know how critical packaging is—not just for protection during transit, but for branding, compliance, and supply

The industrial sector depends heavily on efficient, scalable, and cost-effective packaging—whether it’s for machinery parts, building materials, electronics, or bulk components. But with ongoing tariff

In today’s fast-paced market, packaging needs to be more than just protective—it needs to be agile, customizable, and visually compelling. That’s where digital printing steps

Folding cartons are one of the most versatile forms of retail packaging—and how you print on them can make the difference between a product that

Printed packaging plays a crucial role in brand perception, shelf appeal, and the overall customer experience—but the work doesn’t stop once the ink hits the