Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

Your customers are constantly giving you clues—through reviews, support tickets, returns, and even social media posts. If you’re listening closely, you’ll find that consumer feedback

A great packaging supplier can do more than just deliver boxes or pouches—they can become a valuable partner in your product’s success. When you build

Packaging prices don’t always stay still. Whether due to raw material costs, tariffs, labor increases, or supply chain shifts, price hikes can hit unexpectedly—and impact

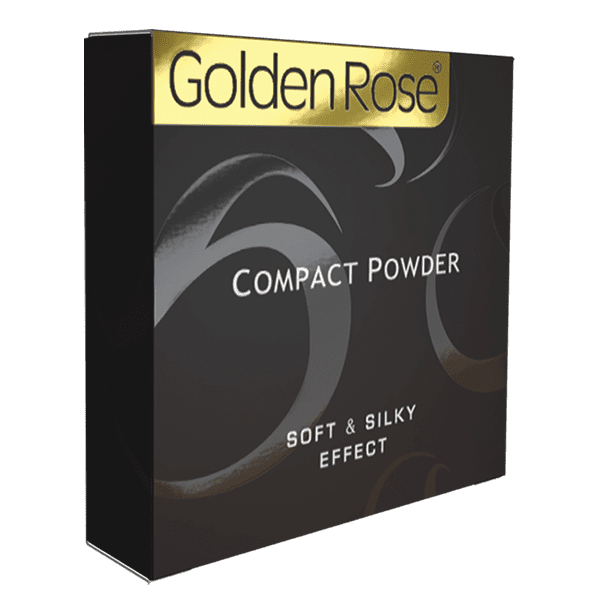

When most buyers think of packaging design, they picture logos, colors, and graphics—but what’s often overlooked is structural design: the way your box is shaped,

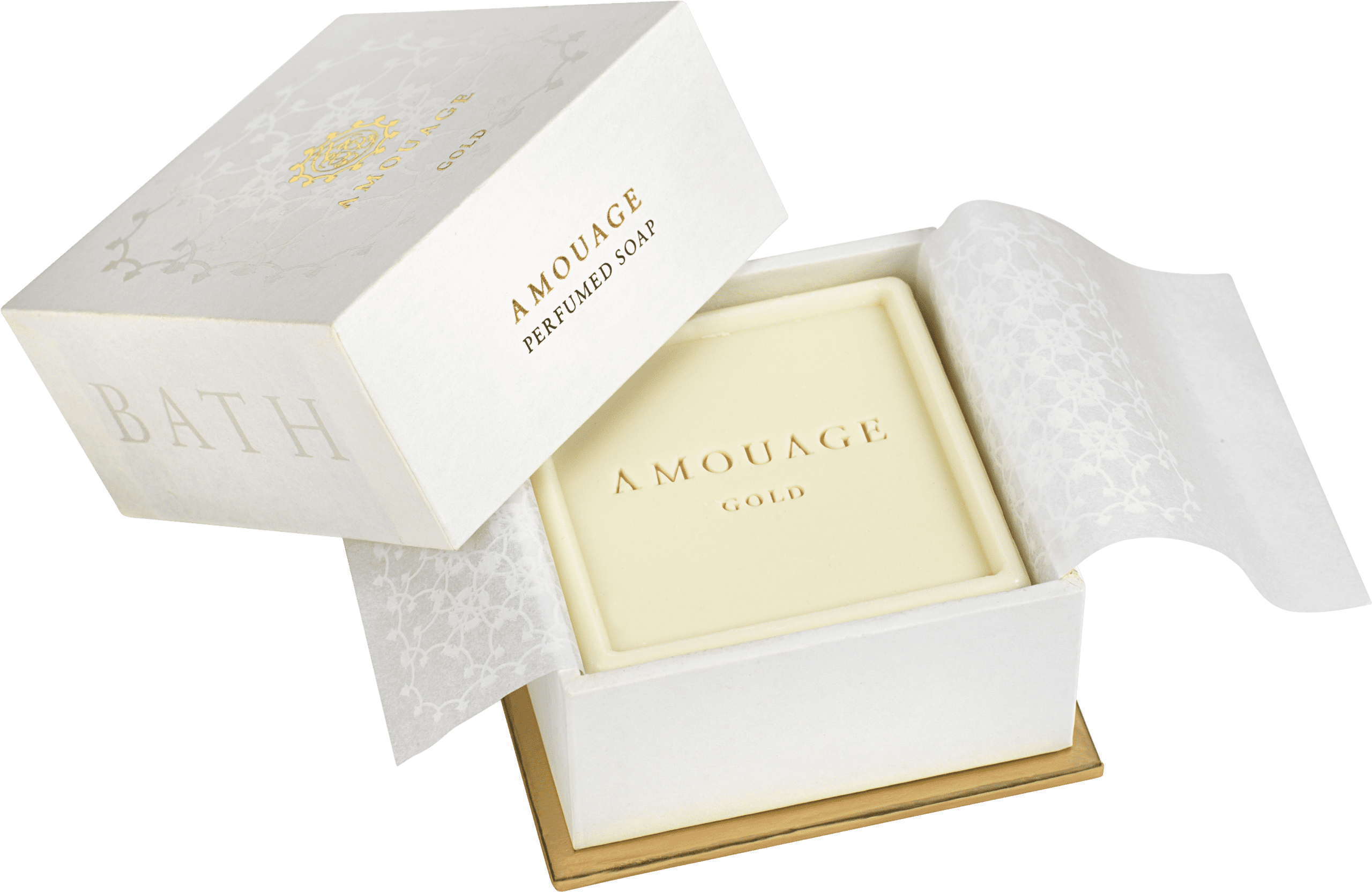

Rigid boxes are the premium standard in packaging—perfect for luxury products, high-end electronics, skincare, and gift sets. But creating a beautiful rigid box is only

Rigid boxes are known for their durability, structure, and high-end feel—but what truly gives them their luxury appeal is the finish. That polished, vibrant exterior

When it comes to maximizing shelf space and capturing buyer attention, few pairings are more effective than folding cartons and POP displays. Whether it’s a

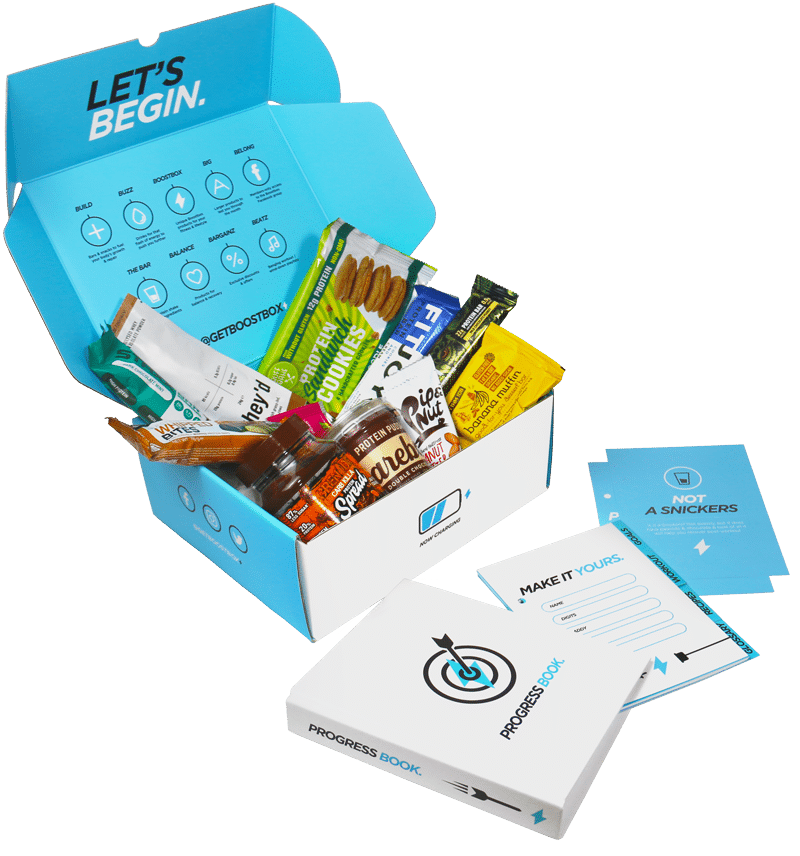

Multi-SKU product lines offer variety, but when it comes to packaging, they also create complexity. Whether you’re offering different flavors, sizes, formulas, or bundle combinations,

Custom pouch packaging is one of the most flexible, lightweight, and brand-forward packaging formats on the market today. From snacks and supplements to beauty and

Packaging isn’t just a box or a bag—it’s a line item on your budget, a touchpoint with your customer, and a critical part of your

Before a customer ever opens your product, they’ve already formed an opinion—based on the packaging. Whether you’re in retail, e-commerce, or B2B, packaging is more

High-end products deserve more than protection—they require packaging that conveys value, craftsmanship, and prestige from the moment it’s seen or touched. Whether you’re selling luxury

Not every product calls for ultra-premium packaging—but that doesn’t mean you have to settle for generic or low-quality. For many brands, the sweet spot lies

With rising tariffs, unpredictable freight costs, and ongoing supply chain delays, more companies are pulling away from overseas packaging and turning to U.S.-based corrugated box

Rigid boxes are known for their premium feel, durability, and high-end presentation, making them the go-to choice for luxury goods, cosmetics, electronics, and gift packaging.

As the retail landscape continues to evolve, staying ahead of the latest trends is crucial, especially during the competitive holiday season. In 2025, Point of

As the 2025 holiday season approaches, retailers are gearing up for what promises to be another bustling period of consumer activity. For brands looking to

For pharmaceutical companies, sourcing packaging has become more complex in recent years. Tariffs on imported materials and printed components are creating pricing pressure, disrupting long-term

Your packaging budget isn’t just about cost—it’s about timing, opportunity, and alignment with your business goals. Sticking with the same spend year after year might

Why Packaging Automation Compatibility Matters As more fulfillment centers, contract packagers, and manufacturers turn to automation, packaging that isn’t compatible with machinery becomes a costly

Evolving Demands, Smarter Decisions As 2026 approaches, packaging decision-makers across sectors—from retail and ecommerce to industrial and medical—face a landscape shaped less by buzzwords and