Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In the highly competitive world of product packaging, brands are constantly seeking innovative ways to capture the attention of consumers. One such innovation that has

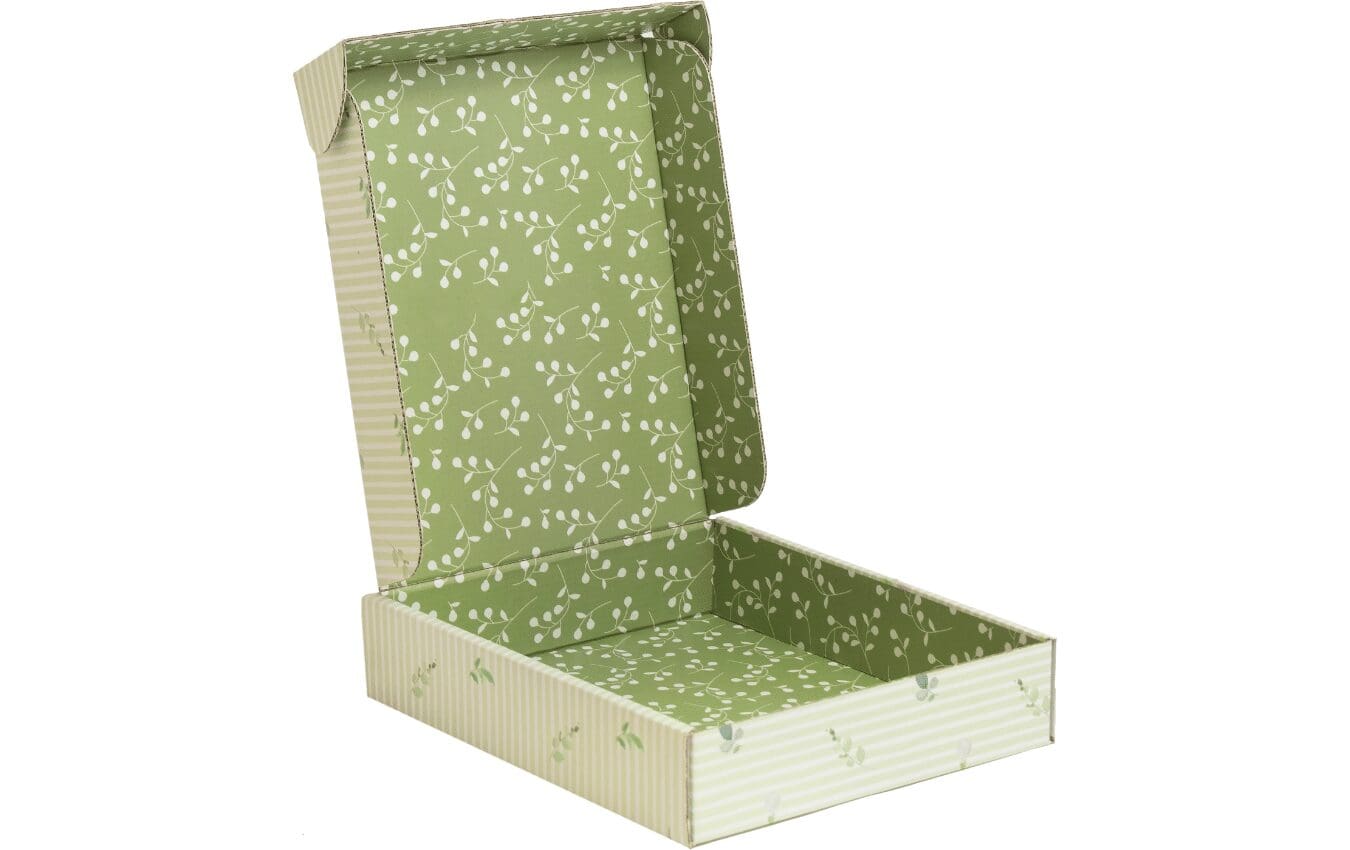

Custom packaging has become a popular trend in recent years, as businesses seek to differentiate themselves and make a lasting impression on their customers. The

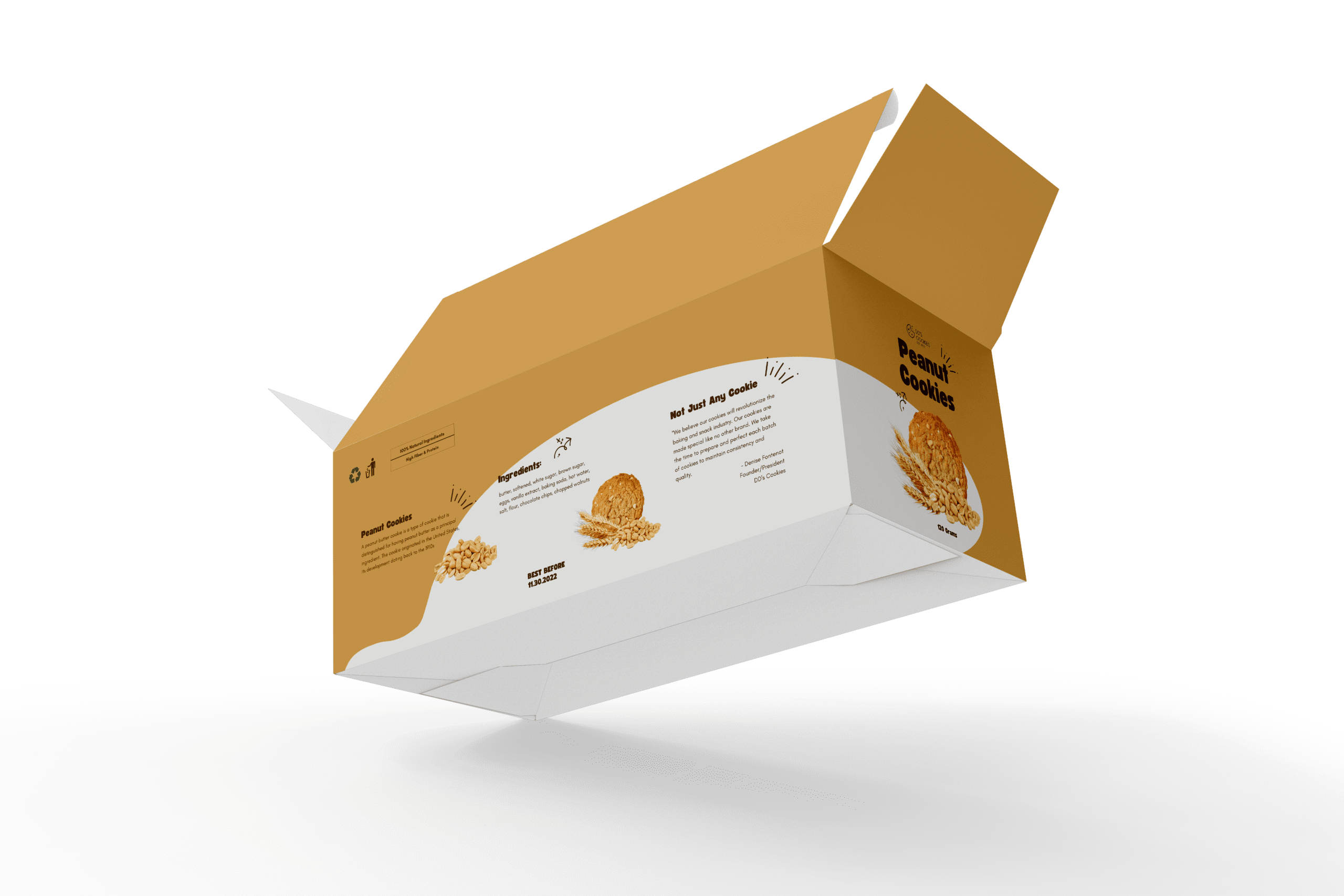

Food packaging is a critical component of the food industry, providing protection, preservation, and marketing benefits for food products. It is an essential element in

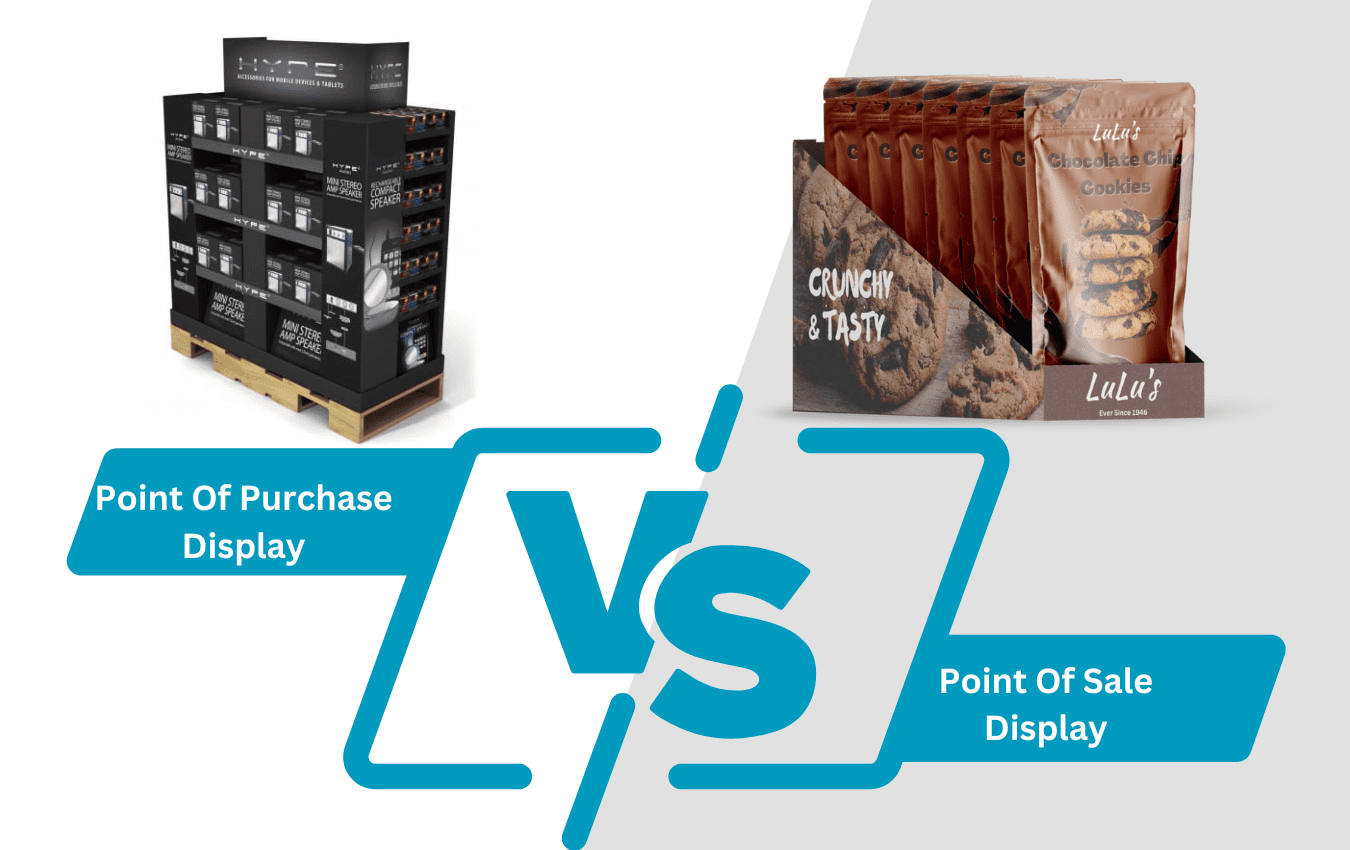

Displays play a key role in marketing and selling your product in stores. With the goal of grabbing the attention of a customer, it is

Corrugated packaging has been a popular choice for packaging and shipping goods for over a century, and for good reason. The unique structure of corrugated

3-side sealed pouches are a type of flat pouches, which consists 3 sides sealed and 1 side open for filling. These pouches are inexpensive to

Packaging is an essential aspect of product marketing, and it can play a significant role in attracting and retaining customers. Effective packaging can make a

Minimalist packaging is a design trend that has taken the packaging industry by storm in recent years. The concept of minimalism is centered around the

The packaging industry has undergone significant changes in recent years, with new technologies such as digital print revolutionizing the way packaging materials are produced. Digital

The increasing demand for consumer goods and the resulting surge in packaging waste have prompted a growing concern for the impact of packaging on the

High density polyethylene (HDPE) and low-density polyethylene (LDPE) are both types of polyethylene, a thermoplastic polymer made from petroleum. The main difference between the two

Corrugated Boxes are exposed to many different circumstances during packing, shipping and storage. Ensuring that your corrugated packaging is protecting your product fully is important.

Sustainability is growing momentum in 2023 for the packaging industry, as many businesses worldwide are looking to further limit their carbon footprint and maximize recyclability.

Point of Purchase (POP) displays are an effective way to promote products and increase sales in retail environments. The trends for POP displays in 2023

Selecting the right packaging for your business is crucial to ensure the safety of your products during transportation and storage, improve your brand image, and

When it comes to packaging and shipping, having the right type of tape can make all the difference. Not only does it ensure that your

Contract packaging, also known as co-packing or third-party packaging, is a service where a company outsources the packaging of their products to a specialized provider.

Corrugated packaging is a popular packaging option for a wide range of products due to its strength, durability, and cost-effectiveness. In 2023, several trends are

Choosing the right printing method for your packaging is very important. It is necessary to consider artwork, design, quantity, time frame and many more when

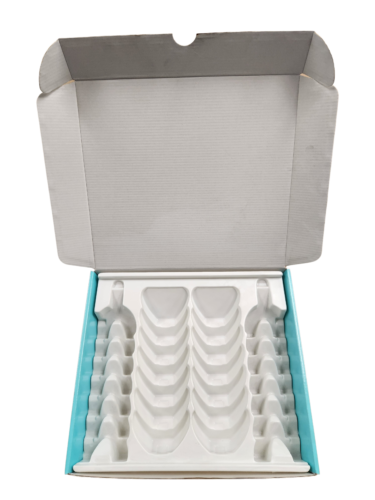

Custom box inserts are used to ensure your products are secure inside your box throughout the supply chain. They are used to keep your product

What is Chipboard? Chipboard is made from small wood particles mixed with resin, binders and other additives, which is then pressed together under high temperature