Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

In today’s fast-paced world, the logistics industry plays a crucial role in ensuring that products are delivered to customers in a timely and cost-effective manner.

Packaging is an essential aspect of any product, and it is vital for the success of small businesses. Effective packaging not only protects the product

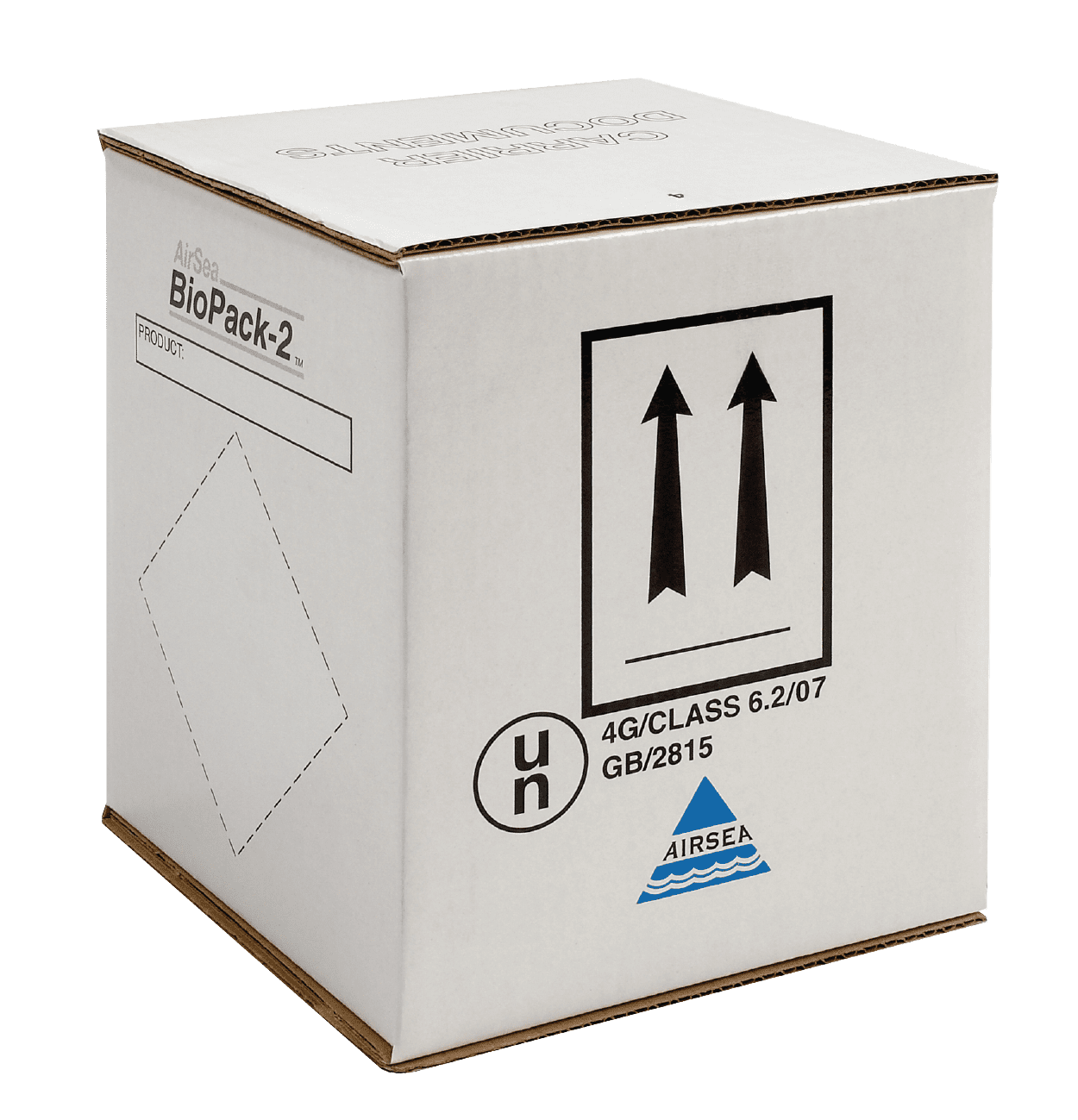

Packaging plays a crucial role in ensuring that products reach their intended destination safely and securely. Without proper packaging, products are likely to suffer damage

In today’s market, packaging plays a crucial role in product sales and branding. It is one of the most critical aspects of a product’s marketing

Lithography in packaging is a process used to print high-quality graphics and text on various substrates, such as plastics and paper. This technique is used

Pressure-sensitive adhesive tapes have been a popular choice for businesses due to their versatile and reliable adhesive solutions. They are used in various industries, including

Packaging plays a crucial role in the success of a product. It not only protects the product from damage but also serves as a medium

Color plays a vital role in brand recognition, and it is especially important when it comes to packaging materials. The color of your packaging can

The packaging of your product is the first impression your customers will have of your brand. It needs to grab their attention, communicate your product’s

Packaging is an essential aspect of any product’s marketing strategy. It is often the first point of contact with the consumer and can greatly influence

Corrugated boxes are an essential part of the shipping and storage process for businesses worldwide. They are made of corrugated paperboard, which comprises three layers:

Packaging plays a crucial role in attracting customers and promoting brand recognition. Companies often spend a lot of time and money designing the perfect package

In today’s world of e-commerce, businesses are constantly searching for ways to differentiate themselves from their competitors. One often overlooked aspect of the customer experience

Summer is a season of warm weather and outdoor activities that brings joy to many people. However, for businesses that rely on packaging to transport

The cold chain is a temperature-controlled supply chain that plays a critical role in ensuring that certain products, such as pharmaceuticals, vaccines, and food, maintain

In recent years, the world has seen a rapid growth in the e-commerce industry. With the convenience of online shopping and the ability to purchase

The importance of packaging in our daily lives cannot be overstated. Packaging protects, preserves, and transports the products we use and consume every day, ensuring

ISTA (International Safe Transit Association) certification is an essential component of the packaging industry. It involves testing and certifying packaging materials and products to ensure

In today’s highly competitive marketplace, the packaging of a product plays a crucial role in determining a brand’s success. It is the first point of

Digital printing has revolutionized the packaging industry in recent years. It has brought a lot of flexibility, creativity, and efficiency to the packaging process. It

Packaging is an essential aspect of product design, as it helps to protect the contents and enhance their shelf life. One of the most versatile