Home » Packaging That Improves Retail Compliance

Packaging That Improves Retail Compliance

Retailers place strict requirements on packaging to ensure products move efficiently through distribution centers, arrive safely, and look consistent on shelves. Non-compliance can lead to costly chargebacks, rejected shipments, and damaged retailer relationships. Buyers must design packaging that meets performance, labeling, and sustainability standards to avoid disruptions.

Why Retail Compliance Matters

- Financial impact: Chargebacks and penalties cut into margins.

- Operational delays: Non-compliant packaging can hold up entire shipments.

- Retailer trust: Consistent compliance builds long-term partnerships.

- Shelf presence: Packaging that aligns with planograms avoids disruptions at store level.

Key Compliance Requirements

- Structural standards: Packaging must meet durability and palletization guidelines.

- Labeling accuracy: GS1-compliant barcodes and proper product details.

- Sustainability mandates: FSC certification or recyclability requirements from major retailers.

- Testing protocols: ISTA or ASTM performance tests to validate protection.

Common Causes of Non-Compliance

- Incorrect pallet sizes or overhang.

- Weak corrugated grades that collapse under stacking.

- Missing or unreadable barcodes.

- Excess packaging waste conflicting with retailer eco goals.

How to Improve Retail Compliance

- Standardize box sizes to match retailer pallet and shelf guidelines.

- Validate packaging with ISTA or ASTM testing before rollout.

- Collaborate with suppliers who understand retailer-specific requirements.

- Audit packaging regularly to stay aligned with updated standards.

Packaging Solutions with Brown Packaging

Brown Packaging partners with companies to design packaging that meets retailer requirements. From GS1 labeling to FSC-certified materials and ISTA-tested corrugated, we help buyers reduce chargebacks and protect retail relationships. Contact us to improve your retail compliance program.

References

GS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org

International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org

Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.org

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » Packaging That Improves Retail Compliance

Retailers place strict requirements on packaging to ensure products move efficiently through distribution centers, arrive safely, and look consistent on shelves. Non-compliance can lead to costly chargebacks, rejected shipments, and damaged retailer relationships. Buyers must design packaging that meets performance, labeling, and sustainability standards to avoid disruptions. Why Retail Compliance Matters Financial impact: Chargebacks and penalties cut into margins. Operational delays: Non-compliant packaging can hold up entire shipments. Retailer trust: Consistent compliance builds long-term partnerships. Shelf presence: Packaging that aligns with planograms avoids disruptions at store level. Key Compliance Requirements Structural standards: Packaging must meet durability and palletization guidelines. Labeling accuracy: GS1-compliant barcodes and proper product details. Sustainability mandates: FSC certification or recyclability requirements from major retailers. Testing protocols: ISTA or ASTM performance tests to validate protection. Common Causes of Non-Compliance Incorrect pallet sizes or overhang. Weak corrugated grades that collapse under stacking. Missing or unreadable barcodes. Excess packaging waste conflicting with retailer eco goals. How to Improve Retail Compliance Standardize box sizes to match retailer pallet and shelf guidelines. Validate packaging with ISTA or ASTM testing before rollout. Collaborate with suppliers who understand retailer-specific requirements. Audit packaging regularly to stay aligned with updated standards. Packaging Solutions with Brown Packaging Brown Packaging partners with companies to design packaging that meets retailer requirements. From GS1 labeling to FSC-certified materials and ISTA-tested corrugated, we help buyers reduce chargebacks and protect retail relationships. Contact us to improve your retail compliance program. References GS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgForest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Retail Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

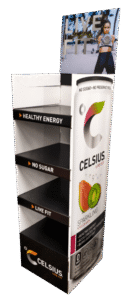

POP displays must balance eye-catching branding with structural integrity. Inadequate load-bearing design can result in product sagging, leaning, or complete collapse, which not only risks product loss but also damages retailer confidence. By applying engineering principles, testing protocols, and correct material selection, brands can maximize display stability without unnecessary cost. Understanding Load-Bearing Capacity Static Load vs. Dynamic Load: Static load refers to the total weight a display can hold without movement. Dynamic load accounts for forces during handling, stocking, and customer interaction. Failure Modes: Panel buckling, shelf deflection, joint separation, and base collapse are the most common failure points. Material Selection Corrugated Board Strength: Flute profile (B, C, E, or BC) impacts stiffness and stacking strength. Higher ECT boards increase vertical load capacity but also affect cost and weight. Coatings and Laminates: Water-resistant coatings prevent fiber weakening in humid environments. Laminates can increase rigidity but may impact recyclability. Structural Reinforcements Double-Wall Shelving: For heavier products such as beverages or canned goods. Internal Braces: Die-cut supports hidden behind the graphic panels for increased stability. Base Skids: Distributes load more evenly to prevent floor contact wear and pallet jack damage. Design and Geometry Weight Distribution: Heavier SKUs should be placed at lower tiers to reduce tipping risk. Joint Engineering: Lock tabs, glue flaps, and interlocking slots improve structural stability. Shear Resistance: Cross-bracing and panel alignment reduce the risk of diagonal collapse. Testing Protocols ASTM D642: Measures compression strength to determine safe stacking loads. ISTA 3A & 6-Series: Simulates real-world handling, vibration, and impact. Shelf Deflection Tests: Measures how much a shelf bends under load over time. Best Practices Always design for at least 25% higher load capacity than the expected maximum product weight. Validate prototypes under realistic load and environmental conditions before production. Balance cost-to-performance ratio — over-engineering increases cost without visible retail benefit. References ASTM International. (2015). ASTM D642-15: Standard test method for determining compressive resistance of shipping containers. ASTM International. https://www.astm.org/d0642-15.htmlInternational Safe Transit Association. (2018). ISTA 3A general simulation performance test for packaged-products for parcel delivery system shipment. ISTA. https://ista.org/International Safe Transit Association. (2018). ISTA 6-Series transit tests. ISTA. https://ista.org/ (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

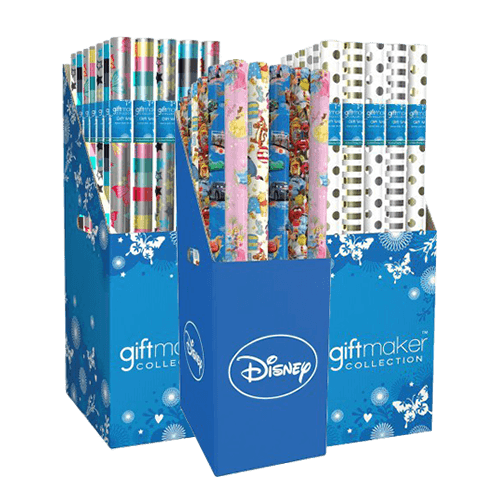

Point of Purchase (POP) displays are a crucial element in the world of retail marketing. They play a significant role in catching the eye of shoppers and encouraging impulse purchases. One specific type of POP display that’s widely used is the “Dump Bin.” In this blog, we will delve into what POP display dump bins are, their benefits, how they work, and why they are essential for retailers and brands alike. What are POP Display Dump Bins? Definition and Purpose POP display dump bins, often simply referred to as “dump bins,” are open-top containers or bins used in retail environments to display a variety of products. These bins are strategically placed throughout the store, typically near checkout counters, entrances, or high-traffic areas, to capture shoppers’ attention and promote spontaneous buying decisions. Construction and Design Dump bins come in various shapes, sizes, and materials, but they share a few common features. They are open at the top, allowing easy access to products, and they often have slanted sides for better visibility. Dump bins can be made from cardboard, plastic, wire, or even wood, depending on the retailer’s branding and the intended use. How Do Dump Bins Work? Product Placement Retailers carefully select the products they want to promote using dump bins. These products are typically smaller or lower-priced items that are ideal for impulse purchases, such as candies, small toys, or seasonal items. Strategic Placement Dump bins are strategically placed at key locations within the store. For example, near the checkout counter, customers waiting in line are more likely to make additional purchases when they see enticing items in the bin. Visual Appeal Dump bins are designed to be eye-catching. The open, inviting design allows shoppers to see the products easily. Retailers often use colorful signage, branding, and graphics to draw attention to the bin. Accessibility Dump bins are designed for convenience. Shoppers can easily reach in and grab the products they desire without the need for a shopping cart or basket. This accessibility encourages quick, spontaneous purchases. Benefits of Using Dump Bins Increased Sales Dump bins can significantly boost sales, especially for impulse-driven products. Customers who may not have originally intended to purchase these items are more likely to do so when they see them prominently displayed. Enhanced Brand Visibility Dump bins offer an excellent opportunity for brand exposure. Retailers can use these bins to showcase their branding, logos, and taglines, reinforcing their presence in the customer’s mind. Efficient Inventory Management Dump bins can help retailers move excess inventory or promote seasonal items effectively. They create a designated space for these products, preventing them from cluttering the store shelves. Customer Engagement Dump bins engage customers on a sensory level. Shoppers can touch, pick up, and examine the products in a hands-on manner, which can lead to a stronger connection with the brand. Why are Dump Bins Essential? Adaptability Dump bins are versatile and can be used across various industries and retail settings, from grocery stores to clothing boutiques. Their adaptability makes them a valuable tool for marketers. Cost-Effective Dump bins are a cost-effective way to increase sales and brand visibility without significant investments in store redesign or advertising campaigns. Encourage Impulse Buying In the world of retail, impulse purchases can make a significant impact on a business’s bottom line. Dump bins are designed to tap into this consumer behavior effectively. Enhanced Shopping Experience By providing customers with an enjoyable and interactive shopping experience, dump bins contribute to overall customer satisfaction and loyalty. If you are interested in POP display dump bins, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts