Home » The Role of Board Grade in Supply Chain Resilience

The Role of Board Grade in Supply Chain Resilience

Why Board Grade Selection Matters

In today’s volatile supply chain environment, packaging failures aren’t just a nuisance—they’re a liability. Damage in transit, product returns, and load instability all lead back to one foundational element: board grade. Whether you’re shipping across the country or staging products for long-term storage, the right corrugated board strength directly impacts product integrity, compliance, and bottom-line efficiency.

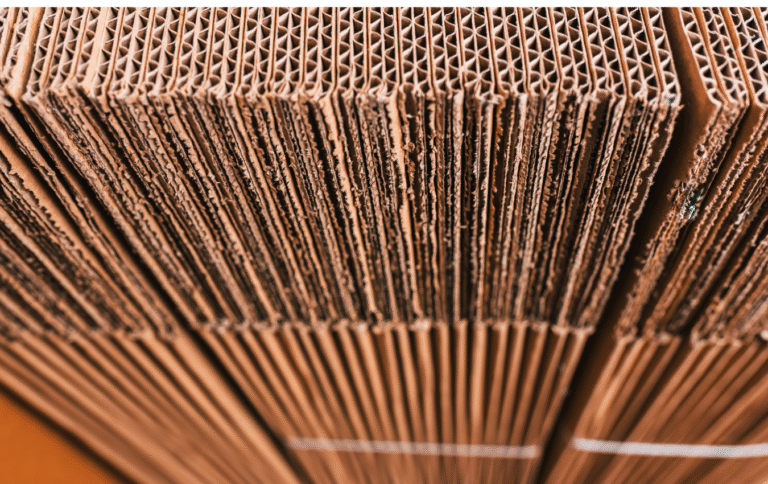

Understanding Board Grade Classifications

Corrugated board grade is defined by its burst strength (measured in pounds), edge crush test (ECT) rating, or basis weight in pounds per 1,000 square feet. The two most common standards:

- Mullen Test (Burst Strength): Measures resistance to puncture or rupture under pressure (e.g., 200#).

- Edge Crush Test (ECT): Measures stacking strength and compression resistance along the edge (e.g., 32 ECT).

Higher board grades offer greater durability but come at a cost—so matching board performance to supply chain risk is key.

How Board Grade Supports Supply Chain Resilience

✔ Reduces Transit Damage

Heavier board grades (like 44 ECT or 275#) are essential for heavier items or mixed-pallet shipping. They prevent crushing under load and protect high-value products from collapse or impact.

✔ Improves Stacking Stability

If your supply chain includes warehousing, transloading, or racking, poor stacking strength leads to bottom-box failures. ECT-rated boxes offer predictable stacking loads, enabling more reliable palletization strategies.

✔ Adapts to Environmental Stressors

In humid or high-temperature zones, lower-quality board can warp or delaminate. Upgrading to moisture-resistant coatings or wax-treated grades extends package integrity in unpredictable conditions.

✔ Meets Carrier and Retailer Compliance

Major carriers and retailers (e.g., Amazon, Walmart) often require packaging that meets minimum board grade thresholds for specific product categories. Failing to comply can result in chargebacks or denied loads.

Matching Board Grade to Application

- Lightweight Goods (<30 lbs): 32 ECT or 200# is often sufficient for controlled distribution.

- Midweight/Stacked Goods (30–65 lbs): 44 ECT or 275# single-wall offers better stability.

- Heavy or Fragile Items: 48 ECT+, 350# double-wall, or even triple-wall is standard for machinery, appliances, or multi-SKU master packs.

- Export Shipments: Double-wall with moisture resistance is critical for sea containers and extended transit.

Why Resilience Now Means Cost Efficiency Later

Skimping on board grade may reduce material costs short-term, but it increases risks throughout the supply chain:

- Higher damage rates

- Increased return logistics

- More manual rework at DCs

- Lower pallet efficiency

By engineering packaging with the right board spec, brands can build flexibility into distribution—whether absorbing shock during LTL shipping or maintaining load stability during storage.

Final Thoughts

Your corrugated board grade isn’t just a spec—it’s a strategic decision that drives supply chain resilience. From minimizing product loss to meeting compliance and stacking standards, choosing the right board means fewer disruptions and greater operational continuity. At Brown Packaging, we help businesses select, test, and implement the right corrugated materials based on real-world demands.

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Home » The Role of Board Grade in Supply Chain Resilience