Home » Smart Packaging Decisions for a Cost-Conscious Market

Smart Packaging Decisions for a Cost-Conscious Market

Every brand is feeling the squeeze — higher raw material costs, volatile freight rates, and a consumer base more price-conscious than ever. But cutting packaging budgets blindly can lead to damaged goods, compliance issues, and eroded brand value. Smart brands aren’t chasing cheaper boxes — they’re making smarter packaging decisions that balance performance, cost, and perception.

The difference between saving money and losing value comes down to how you evaluate your packaging, not just what you pay for it.

Beyond Unit Price: Understanding Total Packaging Cost

A low unit price might look great on paper — until you factor in assembly time, damage rates, and freight efficiency. Smart packaging evaluation considers the total cost of ownership, including:

- Material yield (how efficiently sheets convert into boxes)

- Pallet and trailer utilization (freight optimization)

- Labor efficiency (ease of assembly or automation compatibility)

- Product protection (damage rates, replacements, and returns)

When buyers assess all these metrics, the lowest-cost box often isn’t the best-value box.

Material Selection That Saves in the Long Run

Switching materials isn’t just about cutting cost — it’s about reducing waste and improving performance. For instance, moving from double-wall to a high-performance single-wall with better flute structure can cut weight and shipping cost without sacrificing protection.

In folding cartons, substrate optimization — using a lighter caliper SBS or switching to coated recycled board — can yield savings that scale across production runs. And for rigid boxes, structural tweaks like thinner chipboard paired with strong wrap papers can preserve presentation while reducing material use.

Every small change adds up when you scale across thousands of units.

Design Efficiency: The Overlooked Cost Saver

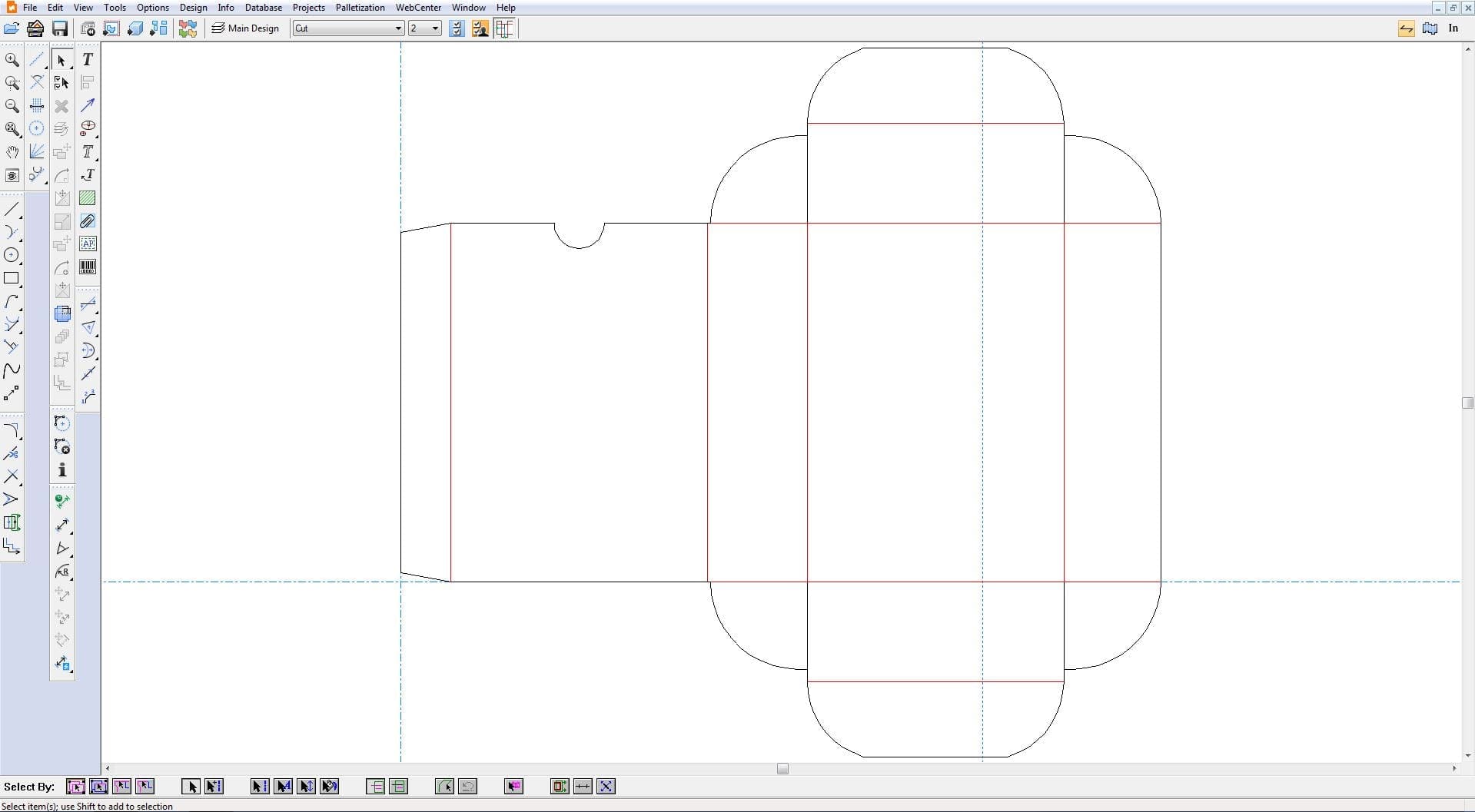

A smart structural design can eliminate cost before production even starts. Simplifying folds, reducing glue flaps, or reengineering inserts can cut assembly time and material waste.

Modern packaging engineers use CAD-based dieline analysis to optimize layouts — ensuring maximum sheet yield and minimal offcut. For e-commerce and retail brands alike, right-sizing packaging improves shipping efficiency and reduces filler materials while maintaining the brand’s polished look.

It’s not just design — it’s design that earns its keep

Printing Smart: Matching the Process to the Purpose

Not every job needs premium litho or complex spot varnishes. A good packaging partner matches print method to scale and brand intent:

- Flexo printing for high-volume, cost-efficient runs.

- Digital printing for short runs, personalization, and multi-SKU campaigns.

- Litho laminating for high-end visuals in rigid or premium retail displays.

By choosing the right print method early, brands can avoid over-engineering — saving both time and money without compromising quality.

Data-Driven Decisions: The New Standard for Packaging Buyers

Leading companies now use data to guide packaging spend. Damage rate metrics, SKU-level freight analysis, and consumer perception studies all contribute to smarter choices.

Smart buyers are no longer asking, “What’s the cheapest box?” They’re asking, “What’s the most efficient box that protects the product, ships well, and supports brand goals?”

This mindset shift is what separates cost-cutting from cost control.

The Brown Packaging Approach

At Brown Packaging, we help brands make smarter packaging decisions by combining engineering analysis, supplier network leverage, and real-world testing.

Our process aligns packaging performance with total cost goals — from box design to print selection and logistics. The result: stronger packaging, lower waste, and sustainable cost savings that scale with your business.

Because in today’s market, smart packaging isn’t just a cost center — it’s a competitive advantage.

References

- PMMI. (2025). Operational Cost Efficiency in Packaging and Logistics.

- McKinsey & Company. (2024). Total Cost of Ownership in Consumer Goods Packaging.

- Packaging World. (2025). Data-Driven Decisions in Packaging Sourcing.

- Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.).

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are learning that premium doesn’t always

Home » Smart Packaging Decisions for a Cost-Conscious Market