Home » Reducing Freight Costs with POP Displays

Reducing Freight Costs with POP Displays

Freight is one of the largest cost drivers in retail packaging programs. Point-of-purchase (POP) displays that look impressive on the floor may be inefficient to ship, leading to wasted space, higher freight charges, and reduced margins. By designing POP displays with logistics in mind, brands can reduce transportation costs without sacrificing retail impact.

Why Freight Costs Matter in POP Programs

Shipping inefficiency adds up quickly across high-volume campaigns. Displays that do not cube out effectively—or require excessive protective packaging—cost more to move and handle. In some cases, freight expenses outweigh the cost of the displays themselves.

Designing POP Displays for Shipping Efficiency

- Flat-pack design: Displays that ship knocked down reduce cubic volume.

- Right-size engineering: Minimize excess corrugated or void space.

- Lightweight materials: Reduce overall shipping weight.

- Stacking strength: Displays must withstand compression during pallet transport.

Balancing Shipping and Retail Needs

Designers must ensure that cost savings on freight do not compromise in-store performance. Best practices include:

- Testing displays for stability after flat-pack assembly.

- Using reinforced corrugated grades where stacking is required.

- Designing displays that integrate seamlessly with pallets.

- Coordinating with logistics teams early in the design process.

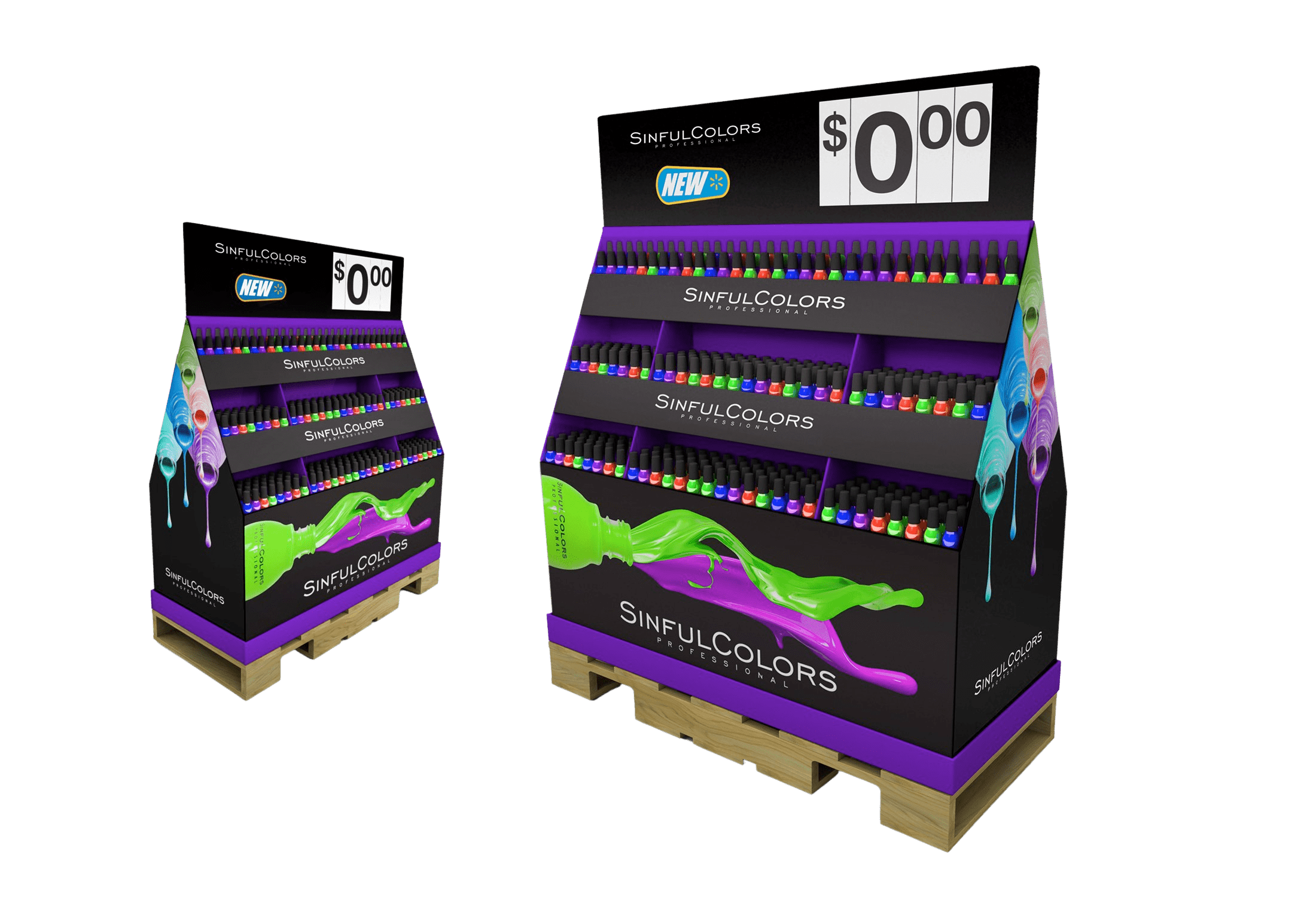

Examples of Freight-Efficient POP Displays

- Club store pallet displays: Engineered for direct-to-floor placement.

- Seasonal promotions: Lightweight designs shipped compactly in bulk.

- Floor stands: Collapsible displays that expand on-site without excess packaging.

POP Display Solutions with Brown Packaging

Brown Packaging designs POP displays that balance retail impact with freight efficiency. Our solutions reduce logistics costs while ensuring displays perform as intended in-store. Contact us to explore freight-efficient POP display options.

References

Shop! Association. (2021). Best Practices for In-Store Marketing and POP Displays. Retrieved from https://www.shopassociation.org

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Reducing Freight Costs with POP Displays