Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

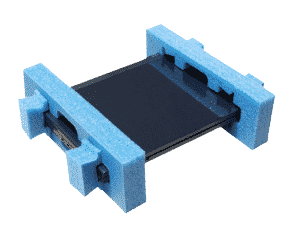

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

Ensuring that products arrive in perfect condition is a top priority for e-commerce businesses, as damaged items can lead to returns, bad reviews, and loss of customer trust. To prioritize durability and protection in your e-commerce packaging, you should focus on several key strategies: Select the Right Materials Use Protective Inserts Right-Size Your Packaging Secure Sealing Test Packaging Durability Consider the Entire Supply Chain Choose Sustainable Yet Durable Materials Select the Right Materials The foundation of durable packaging lies in using the right materials. Strong, high-quality materials can better withstand the stresses of shipping and handling. Corrugated Boxes: These are widely used for shipping because of their strength and durability. Double-wall or triple-wall corrugated boxes provide extra layers of protection, making them ideal for heavier or fragile items. Padded Mailers: For smaller or more delicate items, padded mailers (with bubble wrap or foam lining) offer extra cushioning while being compact. Rigid Mailers: For documents or flat items that need to avoid bending, rigid mailers are a good choice to protect against damage during transit. By choosing materials that are appropriate for your product’s size and fragility, you can significantly reduce the risk of damage. Use Protective Inserts Inserts provide an extra layer of protection inside the packaging. They help to secure the product in place and absorb impact from movement or drops during transit. Foam Inserts: Custom foam inserts or molded pulp inserts are ideal for protecting fragile or sensitive products like electronics, cosmetics, or glassware. Corrugated Dividers: For multiple items being shipped in the same package, corrugated dividers ensure each product is isolated and protected from collisions with other items inside the box. Air Cushions and Bubble Wrap: For products with irregular shapes, bubble wrap, paper void fillers or air pillows can help fill voids and provide cushioning. The right inserts are critical for absorbing shock and preventing products from shifting, which is one of the main causes of damage during shipping. Right-Size Your Packaging Using oversized boxes leads to excess movement of products inside the package, increasing the chances of damage. Right-sizing your packaging to fit your product snugly minimizes the need for excess filler material and ensures the product is secure. Reduce Void Space: Design packaging that minimizes empty spaces inside the box. This reduces the need for additional packing materials and keeps the product from shifting during transit. Custom Packaging: Consider using custom-fit boxes that are designed specifically for the size and shape of your product. Custom packaging not only offers better protection but also gives your product a more professional appearance. Right-sized packaging also reduces shipping costs by decreasing the dimensional weight of the package, benefiting both your bottom line and the environment. Secure Sealing Durability isn’t just about the box itself—secure sealing is essential to keep the contents safe and intact during transit. Reinforced Tape: Use heavy-duty packaging tape, especially for larger or heavier boxes. Water-activated tape (also known as gummed tape) provides a tamper-evident seal and is more durable than standard tape. Double-Sealing for Fragile Items: For extra protection, consider using multiple layers of tape or reinforcing vulnerable areas of the box, such as the corners and edges, where impacts are more likely to occur. Tamper-Evident Seals: These seals ensure that customers can identify whether the packaging has been opened or tampered with, offering an extra layer of protection and peace of mind. Test Packaging Durability Before committing to a packaging solution, conducting real-world durability tests ensures that your products are protected throughout the shipping process. Drop Tests: Simulate shipping conditions by performing drop tests from different heights to assess how well the packaging holds up to impact. Compression Testing: Test how well your packaging can withstand weight and pressure, especially for items that may be stacked during shipping or storage. Environmental Testing: For products shipped in extreme conditions (hot, cold, or humid environments), test how your packaging materials react to these conditions to ensure the product’s integrity remains intact. Testing helps you identify weak points in your packaging design and gives you the opportunity to make improvements before issues arise with customers. Consider the Entire Supply Chain Your product’s journey doesn’t end when it leaves your warehouse. To ensure durable and protective packaging, consider every step of the supply chain, from your packaging facility to the final delivery. Third-Party Logistics (3PL) Handling: Ensure that your packaging can withstand the handling practices of third-party shipping and logistics companies. This includes drops, stacking, and rough handling. Carrier Requirements: Some carriers have specific packaging guidelines for certain products (like fragile items or hazardous materials). Adhering to these guidelines reduces the risk of damage and ensures smooth shipping. By understanding how your product will be handled at each stage of the supply chain, you can better design your packaging to prevent damage and ensure safe delivery. Choose Sustainable Yet Durable Materials Sustainability and durability don’t have to be mutually exclusive. Many eco-friendly materials can offer excellent protection while reducing your environmental footprint. Recycled Corrugated Boxes: Boxes made from recycled materials are just as durable as virgin fiber boxes, but have the added benefit of being more sustainable. Biodegradable Packing Materials: Biodegradable air cushions, packing peanuts, and bubble wrap offer protective cushioning while minimizing environmental impact. By choosing sustainable materials that also prioritize durability, you meet customer expectations for eco-consciousness while ensuring their products arrive in perfect condition. Conclusion Prioritizing durability and protection in your e-commerce packaging is essential for reducing damage, improving customer satisfaction, and minimizing return rates. By selecting the right materials, using protective inserts, and optimizing your packaging design, you can create a packaging solution that not only protects your products but also enhances the overall customer experience. Regular testing and adapting your packaging to the realities of the supply chain ensure that your packaging is fit for purpose and durable enough to handle the rigors of shipping. If you’re interested in ecommerce packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design

When planning a Point of Purchase (POP) display, the first and arguably most critical step is to clearly define your objectives. Setting specific, actionable goals early in the process sets the foundation for all subsequent decisions—from design to placement, and even the materials used. This blog explores how to effectively understand and set objectives for POP displays to ensure they meet your business needs and drive desired outcomes. Importance of Clear Objectives Understanding the purpose of your POP display is essential. Without clear goals, it’s difficult to measure success or make informed decisions during the design and implementation phases. Clear objectives help align your team, streamline the design process, and ensure that every element of the POP display works towards a common end. Common Goals for POP Displays Increasing Brand Awareness For many businesses, POP displays are a tool to enhance brand visibility and recognition. If this is your goal, focus on designs that strongly feature your brand’s logos, colors, and themes. The display should be placed in high-traffic areas to maximize exposure to new and existing customers. Promoting a New Product Launching a new product with a POP display can dramatically affect its initial market performance. For new product promotions, the display should be designed to educate customers about the product features and benefits, encouraging trial and adoption. Interactive elements such as QR codes linking to product demonstrations or reviews can be highly effective. Boosting Sales of an Existing Product If the goal is to increase sales for an existing product, your POP display should focus on creating a sense of urgency or highlighting the value of the product. This might include time-limited offers, discounts, or bundling with other products. The messaging should be persuasive and direct, driving customers to make a purchase decision on the spot. Steps to Define Your Goals Analyze Your Market and Audience Start by understanding who your customers are and what drives their purchasing decisions. Market research can provide insights into customer behaviors, preferences, and trends. This information is invaluable in tailoring your POP display to appeal directly to your target audience. Identify Key Performance Indicators (KPIs) Once you’ve defined your goals, establish KPIs to measure the effectiveness of your POP display. For brand awareness, metrics might include the number of customer interactions or social media mentions. For sales promotions, track the increase in sales volume or revenue generated from the products featured in the display. Collaborate with Stakeholders Engage with various stakeholders, including marketing teams, sales staff, and even customers, to gather insights and feedback. This collaborative approach can help refine your objectives and ensure they are realistic and achievable. Be S.M.A.R.T Ensure your goals are Specific, Measurable, Achievable, Relevant, and Time-bound. This S.M.A.R.T framework helps create objectives that are not only clear but also actionable and aligned with your overall business strategy. Conclusion Defining clear objectives for your POP displays is more than a preliminary step; it’s a strategic action that influences every aspect of your campaign. By setting well-defined goals, you can design POP displays that not only attract attention but also effectively convey your message and achieve desired outcomes. Whether increasing brand awareness, introducing new products, or boosting sales, the right objectives will guide your efforts towards success in the competitive retail landscape. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to packaging, the roll-end tuck top (RETT) box is a versatile solution that seamlessly transitions between the realms of retail and e-commerce. In this blog, we will explore the dynamic ways in which RETT boxes are used in these two distinct worlds. Beyond the traditional comparisons, we’ll dive into the nuances, highlighting how design, branding, features, functions, and purpose evolve to cater to the unique demands of each sector. Designing for the Shelf or the Cart Design Considerations in Retail In the physical realm of retail, the design of RETT boxes is all about commanding attention on the shelf. The focus is on aesthetics and shelf appeal. The box becomes a piece of art, often featuring unique shapes, bold colors, and captivating graphics. Here, it’s all about capturing the customer’s gaze. Design Considerations in E-commerce In contrast, e-commerce RETT boxes are designed for functionality and durability during transit. Shape and color remain important, but the primary focus shifts towards ensuring the box safeguards the product until it reaches its final destination. Sturdiness and size are key considerations, as the box must withstand the rigors of the shipping process. Retail Ecommerce The Brand’s Silent Ambassador Branding in Retail In retail, the packaging serves as a brand ambassador. Boxes are adorned with vivid brand logos, striking taglines, and captivating imagery. Each box becomes a piece of a brand’s story, instantly recognizable and invoking a sense of trust and familiarity. Branding in E-commerce E-commerce RETT boxes extend the brand’s influence beyond the physical realm. They often include elements like QR codes for online engagement, creating a seamless transition from the box to the digital world. The unboxing experience becomes a powerful opportunity to reinforce the brand’s identity and values. Features: From Windows to Locks Features in Retail Retail RETT boxes are not just containers; they’re showcases. Many incorporate window panels or die-cut shapes that allow customers to peek at the product inside. Magnetic closures, embossed logos, and intricate detailing add an air of luxury and exclusivity. Features in E-commerce E-commerce RETT boxes prioritize secure closures and easy access. Tuck flaps, cherry locks, or dust flaps are often integrated to ensure the product arrives intact. These features enhance the unboxing experience, turning a simple delivery into a moment of anticipation and excitement. Functionality: Protecting and Presenting Functionality in Retail In the retail environment, RETT boxes provide both protection and presentation. They keep products safe on shelves while captivating customers with their attractive exteriors. These boxes serve not only as packaging but also as storage and gift wrapping. Functionality in E-commerce E-commerce RETT boxes play a dual role. Their primary function is to ensure the product’s safety during transit, reducing the risk of damage. Simultaneously, they serve as the initial layer of presentation upon arrival at the customer’s doorstep, offering a sneak peek of what’s inside. Purpose: From Shelves to Doorsteps Purpose in Retail In retail, RETT boxes facilitate the purchase decision. They capture attention, convey essential product information, and ultimately drive sales. These boxes are a vital part of the in-store experience, influencing buying choices. Purpose in E-commerce In e-commerce, RETT boxes have a dual purpose. They protect the product during shipping, reducing the chances of damage or breakage. Furthermore, they enhance the unboxing experience, transforming a mere delivery into a memorable and shareable moment. Embracing Sustainability Both retail and e-commerce sectors are increasingly focusing on sustainable packaging practices. RETT boxes are no exception. In both settings, they are evolving towards eco-friendly materials and designs, aligning with the global commitment to reducing environmental impact. Conclusion: Adaptable Ambassadors Roll End Tuck Top (RETT) boxes prove their adaptability as versatile packaging solutions that seamlessly transition between the domains of retail and e-commerce. Beyond their physical attributes, these boxes carry the brand’s identity and message, whether on a store shelf or within the confines of a customer’s home. In the end, RETT boxes are ambassadors that reflect the essence of the brand, ensuring that products make a lasting impression, whether they are showcased in a physical store or unboxed in the comfort of a customer’s home. If you are interested in RETT boxes for either retail or ecommerce, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Roll End Tuck Top Facebook Twitter LinkedIn Pinterest Relevant Posts

Creating custom packaging is a detailed process that requires careful planning and collaboration to ensure the final product meets your needs and expectations. Understanding the timeline for each phase—from design and sampling to delivery—helps manage expectations, streamline communication, and avoid delays. This guide outlines the key stages in the custom packaging process, providing an estimated timeline for each step to help you plan effectively. Phase 1: Design & Sampling Estimated Time: 1–3 Weeks This initial phase is where ideas are transformed into tangible concepts. It involves collaborating with a packaging design team to create a packaging solution that fits your product’s specifications, branding, and functional requirements. Key Steps: Concept Development Discuss your product, budget, branding, and functional needs with the design team. Develop initial concepts and sketches. Prototyping & Sampling Create physical or digital prototypes based on approved designs. Test samples to ensure they meet quality, durability, and aesthetic standards. Potential Delays: Changes in design direction. Delays in providing product dimensions or artwork files. Phase 2: Art Approvals Estimated Time: 1–2 Weeks Once the design is finalized, it moves to the artwork stage. This is where all visual elements, including logos, colors, and text, are finalized and approved for production. Key Steps: Artwork Preparation Designers prepare print-ready files based on your approved design. Mockups are reviewed to ensure all elements align with brand guidelines. Approval Process Review proofs and request any necessary changes. Provide final approval to move forward with production. Tips for Efficiency: Provide high-resolution logos and branding assets upfront. Assign a dedicated point of contact for approvals to avoid delays Phase 3: Tool Manufacturing Estimated Time: 2–4 Weeks For custom packaging, tooling may be required to create the unique shapes, cuts, and designs specified in your order. This involves producing molds, dies, or plates to prepare for production. Key Steps: Tool Design Engineers design custom tools based on approved specifications. Tool Production Manufacturing the tools required for cutting, printing, or shaping packaging materials. Potential Delays: Revisions to specifications after tooling has started. Complexity of tooling for intricate designs. Phase 4: Production Estimated Time: 3–6 Weeks With designs approved and tools ready, production begins. The timeline for this phase depends on the complexity of your packaging, the materials used, and the order quantity. Key Steps: Material Procurement Sourcing of materials like cardboard, plastics, or printing inks. Printing & Assembly Printing artwork onto materials. Assembling packaging components, such as folding cartons or rigid boxes. Quality Control Inspecting samples from the production line to ensure consistency and quality. Tips for Managing Production Time: Confirm order quantities and specifications before production begins. Choose materials that are readily available to avoid sourcing delays. Phase 5: Delivery Estimated Time: 1–3 Weeks Once production is complete, your packaging is packed and shipped to your designated location. Delivery times depend on shipping methods and distances. Key Steps: Packaging & Logistics Packaging your order for safe transit. Coordinating with logistics partners for shipping. Final Delivery Track shipments to ensure timely delivery. Receive and inspect the order for any damage or discrepancies. Potential Challenges: Shipping delays due to weather or logistical issues. Customs clearance for international deliveries. Estimated Total Timeline Phase Estimated Time Design & Sampling 1–3 weeks Art Approvals 1–2 weeks Tool Manufacturing 2–4 weeks Production 3–6 weeks Delivery 1–3 weeks Total Time 8–18 weeks Tips to Keep Your Project on Schedule Communicate Clearly Provide detailed specifications and feedback promptly at every stage. Plan Ahead Start the custom packaging process early to account for unexpected delays. Work with Trusted Partners Choose a reliable packaging supplier with a proven track record for meeting deadlines. Avoid Last-Minute Changes Finalize designs, quantities, and materials before production begins. Conclusion Creating custom packaging is a multi-step process that requires time and collaboration. By understanding the timeline and potential challenges at each phase, you can plan your project effectively and ensure a smooth transition from design to delivery. Ready to start your custom packaging project? Contact us today to discuss your needs and get started on a timeline tailored to your business! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In today’s competitive market, luxury packaging isn’t just about presenting a product; it’s about crafting an experience. The most successful luxury brands understand that their packaging is an extension of their identity—an immersive, sensory journey that reflects exclusivity, sophistication, and quality. If you want your packaging to resonate with high-end appeal, these seven strategies will help you achieve that goal. Turn Packaging into a Journey Incorporate Sensory Elements Opt for Minimalist Elegance Prioritize Durability and Practicality Choose Premium Materials Add Interactive Features Be Selective with Color Turn Packaging into a Journey Luxury packaging is synonymous with exclusivity and anticipation. Instead of displaying the product outright, create layers of intrigue. Use elements like: Ribbon closures and magnetic flaps to heighten the unboxing experience. Custom inserts and tissue paper for an elegant reveal. Hidden compartments that encourage discovery. Pro Tip: Balance intrigue with ease of access. The process should feel rewarding, not frustrating. Incorporate Sensory Elements Luxury packaging is a multisensory experience. Beyond its appearance, consider how it feels, sounds, and even smells: Texture: Use premium materials like velvet-touch coatings, embossed patterns, or soft-touch finishes to evoke luxury. Sound: Choose materials that produce satisfying, low-pitched sounds—like the subtle creak of a rigid box or the soft rustle of tissue paper. Scent: Infuse your packaging with subtle, complementary fragrances to enhance the overall experience. For example, a hint of leather for luxury goods or floral notes for skincare products. Pro Tip: Align the sensory elements with your brand identity for a cohesive impression. Opt for Minimalist Elegance When it comes to luxury, less is often more. Avoid overwhelming designs and focus on clean, understated aesthetics: Use a single block color with subtle embellishments. Feature a small, elegant logo rather than a bold, oversized one. Experiment with metallic accents (gold, silver, or rose gold) for added sophistication. Pro Tip: Simplicity speaks volumes. Let the quality of your packaging materials do the talking. Prioritize Durability and Practicality Luxury packaging must balance beauty with function. It should: Protect the product during storage and transit. Resist environmental stressors like humidity or temperature changes. Be designed with precision, ensuring components like lids, flaps, and inserts work seamlessly. Pro Tip: Test your packaging under real-world conditions to ensure it maintains its integrity throughout the supply chain. Choose Premium Materials Material selection is critical for creating a high-end look and feel. Consider: Rigid boxes: Known for their durability and premium finish. Recycled kraft paper: A sustainable yet elegant choice. Specialty coatings: Add luxury finishes like gloss, matte, or velvet touch. Pro Tip: Don’t overlook sustainability. Eco-conscious luxury packaging is increasingly appealing to high-end consumers. Add Interactive Features Enhance customer engagement with interactive elements that elevate the unboxing experience: QR codes: Link to exclusive content or personalized thank-you messages. Augmented Reality (AR): Integrate AR features to tell your brand story or showcase product details. Personalized notes: Include hand-signed or printed messages to add a human touch. Pro Tip: Interactive features make customers feel valued, increasing loyalty and word-of-mouth referrals. Be Selective with Color Color conveys a strong emotional message. In luxury packaging, the right palette is crucial: Stick to neutral tones like black, white, or beige for timeless sophistication. Incorporate metallic accents sparingly to enhance the design. Avoid using too many bright colors, which can appear less refined. Pro Tip: Choose colors that align with your brand’s story and the emotions you want to evoke. Why Luxury Packaging Matters Luxury packaging isn’t just an expense—it’s a marketing tool that: Reinforces your brand’s premium positioning. Enhances the perceived value of your product. Creates memorable experiences that drive customer loyalty and advocacy. When done right, your packaging becomes a silent ambassador for your brand, leaving a lasting impression even before the product is used. Ready to elevate your packaging? Contact us today to design packaging that exudes luxury and aligns with your brand’s vision. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts