Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

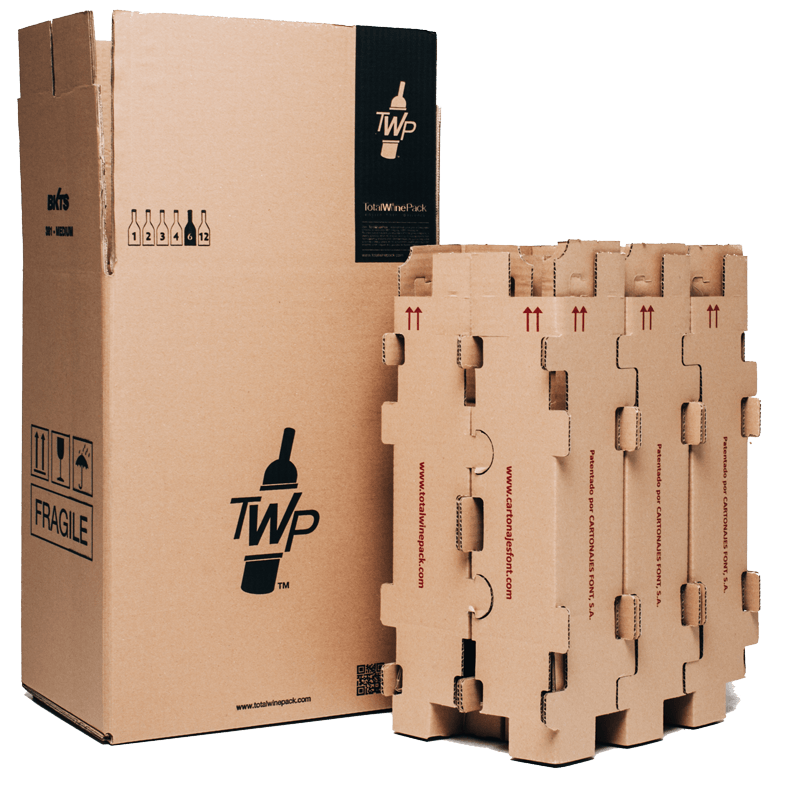

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

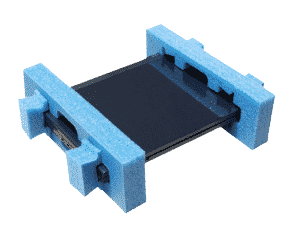

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

In the fast-paced retail environment, capturing the attention of impulse buyers is crucial for boosting sales. Point of Purchase (POP) displays are designed to grab shopper attention at the moment when buying decisions are made, making them a powerful tool for influencing impulse purchases. This blog explores how POP displays can be strategically used to target impulse buyers effectively. Understanding Impulse Buyers Impulse buyers are customers who make spontaneous purchase decisions triggered by seeing the product at that moment. These decisions are often driven by emotional appeal, convenience, or the allure of a good deal. Understanding the psychology of impulse buying is key to designing POP displays that convert passersby into buyers. Designing POP Displays for Maximum Impact Visual Appeal The first step in capturing the attention of an impulse buyer is through striking visual design. Bright colors, bold fonts, and attractive graphics can make POP displays stand out. Incorporating eye-catching elements like flashing lights or digital screens can also draw more attention compared to static displays. Strategic Placement Placement of POP displays can significantly affect their success in capturing impulse buyers. High-traffic areas such as near the checkout lines, at the end of aisles, and close to the store entrance are prime locations. These spots are where customers are most likely to make last-minute purchase decisions. Promotional Messaging Effective POP displays use clear, compelling messages that create a sense of urgency or highlight exclusivity. Phrases like “Limited Time Offer,” “While Supplies Last,” or “Exclusive Deal” can prompt impulse buyers to act immediately to take advantage of the offer before it’s gone. Product Accessibility For an impulse buy to occur, the product must be easily accessible. POP displays should allow customers to easily pick up the product, examine it, and make a quick purchase. Interactive displays that encourage touching and engaging with the product can also increase the likelihood of impulse buys. Leveraging Consumer Behavior Insights Understanding Consumer Habits Analyzing data on consumer behavior and shopping patterns can help tailor POP displays to the habits and preferences of target demographics. For instance, placing snack items in POP displays near the beverage section can capitalize on common buying patterns where shoppers who pick up drinks might also grab a quick snack. Seasonal and Event-Based Targeting Aligning POP displays with seasonal events or holidays can effectively target impulse buyers looking for gifts or celebratory items. For example, chocolate and candy displays are more effective near Valentine’s Day or Easter. Measuring and Adapting Testing Different Approaches Retailers should test various designs and placements of POP displays to see what works best. A/B testing can provide valuable insights into which strategies are most effective at driving impulse purchases. Adapting to Feedback Regularly updating POP displays based on customer feedback and sales data can help maintain their effectiveness. Changing the display’s design, message, or placement in response to observed customer behaviors can optimize their impact. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Pouch packaging has gained immense popularity across various industries due to its convenience, versatility, and eye-catching design possibilities. However, when considering pouch packaging for your products, it’s essential to understand the cost factors associated with it. In this detailed blog, we will break down the cost of pouch packaging and explain how unit costs per 1,000, 10,000, 100,000, and 1,000,000 units work. By the end, you’ll have a clear understanding of what to expect when budgeting for your pouch packaging needs. Determining Pouch Packaging Costs Pouch packaging costs can vary significantly based on several factors. To calculate unit costs for different quantities, consider the following key variables: Pouch Type: The type of pouch you choose, such as stand-up pouches, flat pouches, or custom-shaped pouches, will impact the cost. Specialty or custom-shaped pouches tend to be more expensive. Material Selection: Pouches can be made from various materials, including plastic, foil, or paper. The material choice affects both the cost and the appearance of the pouch. Size and Dimensions: The physical dimensions of the pouch play a significant role in pricing. Larger or irregularly shaped pouches typically cost more. Printing and Design: The complexity of the design and the number of colors used for printing influence costs. Intricate artwork or high-resolution graphics may increase expenses. Quantity Ordered: Economies of scale come into play when ordering larger quantities. Typically, the more pouches you order, the lower the unit cost. Add-On Features: Special features like zippers, spouts, or tear notches can impact the overall cost. These add-ons add both complexity and value to the pouch. Lead Time: Rush orders or tight production schedules may incur additional fees, so planning ahead can help you save on costs. Unit Costs for Different Quantities To better understand how pouch packaging costs scale with quantity, let’s break down the unit cost per 1,000, 10,000, 100,000, and 1,000,000 units. Per 1,000 Units: When ordering a small quantity of pouches (e.g., 1,000 units), the unit cost tends to be higher due to setup and production costs. This is the most expensive option on a per-unit basis. Per 10,000 Units: Ordering 10,000 units typically reduces the unit cost significantly. The setup costs are spread across a larger quantity, making each pouch more cost-effective. Per 100,000 Units: Ordering 100,000 units further decreases the unit cost. The economies of scale become more pronounced, resulting in a considerable reduction in cost per pouch. Per 1,000,000 Units: For larger orders of 1,000,000 units, the unit cost is often the lowest. The efficiencies gained in production, materials, and setup costs result in a highly cost-effective solution. Additional Cost Considerations It’s essential to remember that the unit cost of pouch packaging is not the only expense to consider: Shipping and Handling: Factor in shipping and handling costs, which can vary depending on the weight and volume of the pouches. Design and Artwork: Design and artwork creation may incur separate costs, especially if you require custom graphics or intricate designs. Storage: If you are ordering a large quantity, consider storage costs if you do not have adequate space. Quality Control: Budget for quality control measures to ensure that the final product meets your specifications and standards. Conclusion Understanding the cost of pouch packaging is essential for effective budgeting. It’s crucial to consider factors such as pouch type, material selection, size, design complexity, quantity ordered, and additional features when calculating unit costs. As quantities increase, the unit cost tends to decrease due to economies of scale. By carefully evaluating your packaging needs and planning accordingly, you can make informed decisions that optimize both cost-efficiency and the visual appeal of your pouch packaging. If you are interested in pouch packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

After deploying Point of Purchase (POP) displays, the next critical step is to monitor and evaluate their effectiveness. This phase is essential to understanding the impact of the displays on customer engagement and sales, and it provides valuable insights that can guide future marketing strategies and display designs. This blog details the processes of performance tracking, gathering feedback, and making necessary adjustments to ensure the continual improvement of POP displays. Performance Tracking: Measuring Success Utilizing Sales Data The most direct measure of a POP display’s effectiveness is its impact on sales. Track the sales data of products featured in the display and compare it to sales figures before the display’s installation or with similar products not included in the display. This data provides a clear indication of the display’s ability to convert interest into purchases. Collecting Customer Feedback Gathering feedback directly from customers can provide insights into how the displays are perceived and their influence on buying decisions. Feedback can be collected through surveys, interviews, or even informal conversations at the point of sale. Conducting Observational Studies Observational studies involve watching how customers interact with the display. Note factors such as the time spent at the display, the interaction with products, and the overall traffic. Observational data can help understand customer behavior patterns and engagement levels. Feedback and Adjustments: Continuous Improvement Analyzing Feedback Once data is collected, analyze it to identify trends and patterns. Look for feedback that indicates what customers like about the display and what elements might be causing confusion or disinterest. This analysis can pinpoint what aspects of the display are most effective and which ones need improvement. Implementing Adjustments Based on the analysis, implement adjustments to improve the display. This might involve changing the layout, updating the messaging, or even altering the design elements like colors or lighting. Small, iterative changes can often lead to significant improvements in engagement and effectiveness. A/B Testing To determine which adjustments are most effective, conduct A/B testing by creating different versions of your display. This method allows you to compare results directly and make data-driven decisions about which elements to implement across all displays. Establishing a Routine for Review Regular Reviews Set up a schedule for regular review and maintenance of POP displays. This ensures that displays continue to function as intended and remain visually appealing to customers. Updating Displays Keep displays fresh and relevant by updating them regularly to align with new marketing campaigns, seasonal changes, or new product launches. This not only maintains customer interest but also ensures that the POP displays continue to meet business goals. Conclusion Monitoring and evaluation are critical to maximizing the effectiveness of POP displays. By tracking performance, gathering feedback, and continuously making informed adjustments, businesses can enhance the impact of their displays. This ongoing process not only improves the current displays but also provides invaluable insights that can be applied to future display projects, ultimately leading to better customer engagement and increased sales. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

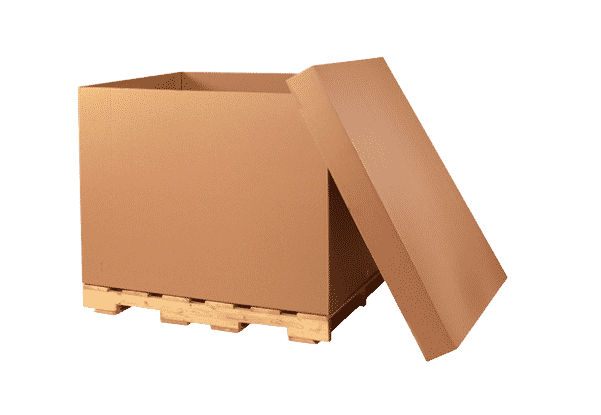

Gaylord containers are large, sturdy boxes used primarily for shipping, storing, and handling bulk materials. Often utilized in industries like manufacturing, agriculture, and retail, these versatile containers are designed to accommodate large volumes of products while providing robust protection. Depending on the specific application, Gaylord containers are available in single, double, and triple wall options, each offering varying degrees of strength and durability. In this blog, we will explore the differences between these options and their practical applications. What Are Gaylord Containers? Gaylord containers, also known as bulk bins or pallet boxes, are large corrugated boxes designed for storing and transporting bulk goods. They are typically mounted on pallets for easy handling with forklifts and other equipment. These containers are highly versatile, accommodating a wide range of materials, including powders, granules, parts, and even irregularly shaped items. Single Wall Gaylord Containers Construction: Single wall Gaylord containers consist of one layer of corrugated cardboard. This layer typically includes a fluted sheet sandwiched between two flat linerboards. Applications: Single wall containers are suitable for lighter materials or products that do not require extensive protection during shipping. They are commonly used for: Lightweight products like plastic parts or textiles Non-fragile items that are not prone to damage Short-distance shipping where minimal handling occurs Benefits: Cost-effective solution for bulk packaging Lightweight and easy to handle Efficient for low-risk, high-volume shipping Double Wall Gaylord Containers Construction: Double wall Gaylord containers feature two layers of corrugated cardboard, providing increased strength and durability compared to single wall options. Applications: Double wall containers are ideal for heavier or more delicate items that require extra protection. Common uses include: Metal parts, automotive components, or hardware Products requiring additional cushioning and support Moderate to long-distance shipping with multiple handling points Benefits: Enhanced strength and durability for heavier loads Better protection against impact and compression Suitable for stacking and efficient space utilization Triple Wall Gaylord Containers Construction: Triple wall Gaylord containers are constructed with three layers of corrugated cardboard, offering maximum strength and resistance to external pressures. Applications: These containers are best suited for the heaviest and most fragile items, providing superior protection during transit and storage. They are often used for: Heavy industrial components or machinery parts Fragile items like glassware or electronics Export shipping, where containers face prolonged handling and rough conditions Benefits: Maximum protection for heavy and fragile goods Optimal for international shipping and storage in harsh environments High resistance to punctures, compression, and impact Choosing the Right Gaylord Container Selecting the appropriate Gaylord container depends on several factors: Weight of Contents: Heavier items require double or triple wall containers for adequate support. Fragility: Fragile products benefit from the added protection of multiple wall layers. Distance and Handling: Longer shipping distances and frequent handling call for stronger container options. Budget Considerations: Single wall containers offer cost savings for less demanding applications, while double and triple wall containers are investments in product safety. Customization and Additional Features Gaylord containers can be customized to meet specific needs, including: Printing and branding for enhanced visibility Coating for moisture resistance Lids and liners for additional protection Dividers and inserts for organized storage Conclusion Gaylord containers are essential for industries requiring efficient and secure bulk packaging solutions. By understanding the differences between single, double, and triple wall options, businesses can choose the right container to protect their products, optimize shipping efficiency, and reduce costs. Whether you need basic packaging for lightweight items or robust protection for heavy machinery, Gaylord containers offer a versatile and reliable solution for all your bulk packaging needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Gaylord Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

When choosing corrugated board for packaging, print quality is often a critical consideration. Two common board types—ECT (Edge Crush Test) board and Bursting Test board, also called Mullen Test board—have distinct surface characteristics that impact the final print results, especially when using flexographic (flexo) printing. While both boards serve their structural purposes, their composition affects ink absorption, print clarity, and overall aesthetics. Why Does ECT Board Struggle With Print Quality? ECT board is designed primarily for stacking strength rather than printing quality. It is rougher and more porous compared to Test board, which results in the following print challenges: Ink Absorption Issues: The more porous nature of ECT board allows ink to spread unevenly, leading to a muddy, less defined print. Uneven Surface Texture: Rough fibers on ECT board prevent fine details and crisp lines from transferring properly, resulting in a blurry or inconsistent appearance. Reduced Ink Holdout: Because the ink penetrates deeper into the material, colors may appear duller and less vibrant compared to smoother boards. Can You Improve Print Quality on ECT Board? For brands requiring higher-quality graphics on an ECT board, one option is to order virgin kraft liners instead of standard recycled liners. Virgin kraft liners: Have a smoother, more uniform surface, allowing for better ink adhesion and sharper details. Reduce ink absorption, leading to brighter, more vibrant prints. Are stronger and cleaner-looking, improving the overall aesthetic of the packaging. When to Use Bursting Test Board Instead Test board, made from a mix of virgin and recycled fibers, tends to be smoother than ECT board, allowing for better ink retention and detail clarity. If print quality is a priority, a Test board with a higher-quality white or coated liner can significantly improve the final result. Final Considerations If your primary concern is cost and stacking strength, ECT board is a solid choice, but expect compromises in print quality when using flexo. For higher-quality branding and graphics, consider upgrading to a Test board or requesting virgin kraft liners to enhance your print results. Need help selecting the right corrugated board for your packaging? Contact Brown Packaging today to find the best option for your needs! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts