Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

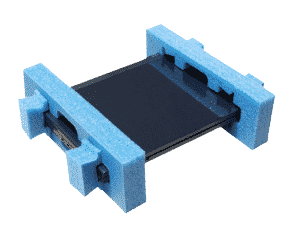

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

As the packaging industry shifts toward more sustainable and efficient solutions, folding cartons are set to play a significant role in 2025. From eco-friendly materials to smart packaging designs, brands are leveraging folding cartons to meet evolving consumer expectations and regulatory demands. Below are the top folding carton trends to watch for in 2025: Sustainable Materials Advanced Digital Printing Custom Design and Personalization Minimalist and Clean Aesthetic Enhanced Durability and Protection Smart and Connected Packaging Flexible Packaging Solutions Recyclable and Compostable Cartons Lightweight and Efficient Designs Cost-Effective Packaging Sustainable Materials Folding cartons in 2025 will prioritize eco-friendly materials, including recycled paperboard and plant-based alternatives. Brands are expected to shift toward FSC-certified materials and other renewable sources, reducing their environmental impact while still offering durable packaging solutions. Advanced Digital Printing With the advancement of digital printing technology, brands will be able to create intricate, high-quality designs on folding cartons more cost-effectively. In 2025, short-run digital printing will become more accessible, allowing for rapid production without sacrificing detail or color, and enabling small businesses to customize their packaging easily. Custom Design and Personalization Consumers increasingly expect personalized experiences, and folding cartons will be a key player in delivering on this expectation. Custom designs, limited-edition packaging, and personalized messaging will be central trends, helping brands create unique, memorable unboxing experiences. Minimalist and Clean Aesthetic Simplicity in packaging design continues to be a dominant trend. The minimalist approach, with clean lines and neutral colors, reflects a focus on sustainability and appeals to consumers seeking eco-friendly, waste-conscious brands. Expect folding cartons with less ink and fewer materials for a streamlined, eco-conscious look. Enhanced Durability and Protection As more products are being shipped globally, folding cartons will evolve to offer better protection without adding excess material. By integrating reinforced corners and innovative structural designs, folding cartons will ensure that fragile items are protected during transit while maintaining sustainability goals. Smart and Connected Packaging Smart packaging will also play a role in folding cartons, with the integration of QR codes and NFC tags allowing consumers to engage with the product or brand directly through their smartphones. This tech will provide information on product authenticity, freshness, and even sustainability efforts, giving consumers a more interactive experience. Flexible Packaging Solutions The demand for more flexible folding carton solutions is growing. In 2025, expect to see more cartons designed for multi-use purposes, such as packaging that can transform into a display or storage container, giving the product’s packaging a second life and minimizing waste. Recyclable and Compostable Cartons Recyclability and compostability will remain top priorities in folding carton trends for 2025. More brands will move towards mono-material designs that enhance recyclability or use compostable materials that break down easily in commercial or home composting environments, ensuring a minimal environmental footprint. Lightweight and Efficient Designs Lightweight folding cartons will grow in popularity as companies seek to reduce transportation costs and emissions. Cartons that use less material but maintain strength and durability will be highly valued by brands focused on optimizing shipping while still protecting their products. Cost-Effective Packaging As the cost of raw materials fluctuates, brands will increasingly seek cost-effective folding carton solutions that balance affordability with sustainability. Innovations in production efficiency and material sourcing will allow companies to maintain high-quality packaging without increasing costs significantly. Folding cartons are evolving to meet the demands of a more sustainability-focused, cost-conscious market. In 2025, businesses that adopt these trends will be better positioned to align with consumer preferences and regulatory requirements while maintaining the flexibility and durability needed for their products. If you’re interested in folding cartons for 2025, whether they are custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Folding Carton Facebook Twitter LinkedIn Pinterest Relevant Posts

In the business landscape, the significance of packaging extends far beyond mere aesthetics or basic product protection. It plays a crucial role in branding, customer experience, and significantly impacts the overall cost structure of a product. Understanding the various elements that drive packaging costs is essential for any business looking to optimize expenses while maintaining quality and appeal. This blog post delves into the most influential factors contributing to your packaging’s costs, ranked by their potential impact. Material Choice At the top of the list is the choice of materials used for packaging. The cost implications here are substantial, as materials not only dictate the cost per unit but also affect transportation, storage, and even waste management expenses. Types of Materials: Options range from economical cardboard to more expensive plastics or metals. Quality and Durability: Higher quality materials that offer better protection or aesthetic appeal often come at a higher cost. Sustainability: Eco-friendly materials can be more expensive but may reduce environmental fees and appeal to a green-conscious market. Design Complexity and Customization The design intricacies of your packaging play a significant role in determining the cost. More complex designs with custom shapes, sizes, or functionality typically require more expensive production processes. Custom Molds and Dies: Unique shapes might need custom production equipment. Printing and Graphics: High-quality prints, multiple colors, and intricate designs add to the production costs. Structural Design: Complex structures that require additional engineering or testing can increase costs. Production Volume The quantity of packaging produced has a direct impact on cost per unit due to economies of scale. Higher Volume, Lower Cost Per Unit: Bulk production usually results in lower costs per unit due to more efficient use of materials and machinery. Small Runs: Smaller production runs can be significantly more expensive per unit due to setup costs and less efficient use of resources. Manufacturing Techniques The chosen method of manufacturing is another critical factor. Advanced techniques like automation can offer cost savings at scale but require significant upfront investment. Manual vs. Automated Processes: Automation reduces labor costs but increases initial investment. Production Speed: Faster production methods can reduce costs but might require more advanced, expensive machinery. Packaging Functionality and Performance The functional requirements of packaging, especially for products that need special handling, can dramatically influence costs. Protection Requirements: More robust packaging for fragile items increases material and design costs. Shelf Life Extension: Packaging that prolongs product life, like vacuum sealing, can be more expensive. Transportation and Storage The cost of shipping and storing packaging materials and the final packaged product is often overlooked but vital. Size and Weight: Bulky or heavy packaging leads to higher transportation costs. Storage Needs: Larger or more sensitive packaging can require more expensive storage solutions. Environmental Compliance and Sustainability Initiatives Adhering to environmental regulations and implementing sustainability initiatives can influence packaging costs. Compliance Costs: Meeting environmental standards can require more expensive materials or processes. Sustainability Programs: Initiatives like recycling programs or the use of biodegradable materials might increase costs but can offer long-term brand benefits. Conclusion In conclusion, packaging costs are influenced by a complex interplay of material choices, design intricacies, production volumes, manufacturing techniques, functionality requirements, logistics, and environmental considerations. Businesses need to carefully evaluate these factors to strike the right balance between cost, quality, functionality, and sustainability. By understanding and optimizing these key influencers, companies can make informed decisions that align with their financial goals and brand values. If you are interested in cost efficient packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Once the design and material selection for a Point of Purchase (POP) display are locked in, the project moves into the critical production phase. This stage is where your concept is transformed into a tangible product ready for retail environments. The key to successful production lies in stringent quality control measures and a well-coordinated manufacturing process. This blog outlines the essential steps and considerations for the production phase of POP displays, ensuring each unit is built to meet both aesthetic and functional standards. Streamlining the Manufacturing Process Setting Up the Production Line The first step in the production phase is setting up the manufacturing line. This setup should be optimized based on the design specifications and material requirements of the POP display. Efficient line setup helps minimize production time and cost, ensuring that each component is assembled correctly and efficiently. Integrating Technology and Automation Where possible, integrating advanced manufacturing technologies and automation can enhance precision and speed in the production process. Automation can be particularly beneficial in producing components that require consistent replication of detailed designs, contributing to uniformity and quality across all units. Implementing Quality Control Measures Developing Quality Standards Before production begins, establish clear quality standards that align with the display’s design and functionality goals. These standards should cover all aspects of the display, including material integrity, color accuracy, structural stability, and overall finish. Continuous Quality Monitoring Implement continuous quality monitoring throughout the production process. This involves regular inspections and testing of the displays at various stages of manufacturing. By catching defects or deviations early, you can prevent issues that might compromise the final product’s effectiveness. Feedback Loop with Design and Materials Teams Maintain a feedback loop with the design and materials teams. This collaboration ensures that any potential issues identified during production can be traced back to design or material choices and addressed promptly, preventing recurrence. Ensuring Compliance with Specifications Adherence to Design Specifications It’s crucial that the manufacturing process adheres strictly to the agreed-upon design specifications. This adherence prevents variations that could affect how the display performs in its intended retail environment and ensures that all functional and aesthetic elements are preserved. Alignment with Material Specifications Similarly, ensure that the materials used in production match the specifications decided during the planning phase. Using the correct materials affects not only the display’s look and feel but also its durability and impact in a store setting. Preparing for Post-Production Assembly and Pre-Installation Checks If the display requires assembly post-production, conduct thorough checks to ensure all parts fit together correctly and that assembly is as straightforward as possible. These checks can help streamline the installation process later on. Final Quality Assurance Before the displays are shipped, a final quality assurance check should be conducted. This final review ensures that every display unit meets your brand’s quality standards and is ready for deployment without needing further modifications. Conclusion The production phase is where your POP display comes to life. By focusing on efficient production setups, stringent quality control, and strict adherence to specifications, you can ensure that the manufactured displays meet the desired standards. Thorough planning and monitoring during this phase lay the groundwork for effective POP displays that attract attention and withstand the demands of the retail environment, ultimately driving sales and enhancing brand presence. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

Why Packaging Strategy Matters Packaging is more than just a protective layer—it plays a vital role in branding, marketing, and customer experience. One of the most important decisions businesses face is whether to use generic packaging, designed for a broad audience, or tailored packaging, customized for a specific market. Each option has its advantages, and the choice depends on factors like cost, brand positioning, and target audience expectations. What is Generic Packaging? Generic packaging is designed to appeal to a wide range of consumers rather than targeting a specific niche. It typically features minimal branding, standardized sizes, and cost-effective materials, making it an ideal choice for businesses focused on mass production and affordability. When to Use Generic Packaging Mass-market products: Items with broad appeal, such as household goods or budget-friendly consumer products. Private label and contract manufacturing: Packaging that needs to work across multiple retailers or brands. Cost-sensitive products: Reduces expenses by minimizing custom design, printing, and material costs. eCommerce fulfillment: Standardized boxes or mailers that streamline warehouse efficiency and reduce shipping costs. ✅ Best for: Generic household goods, subscription boxes, warehouse distribution, and bulk packaging. 🚨 Limitations: Lacks unique branding, may not create a memorable customer experience. What is Tailored Packaging? Tailored packaging is designed to suit a specific audience, product, or industry, often featuring custom shapes, premium materials, or specialized printing to enhance brand recognition and consumer engagement. When to Use Tailored Packaging Luxury or premium products: High-end brands require custom finishes, embossing, and unique structural designs to reflect exclusivity. Niche markets: Products targeted at specific demographics, such as eco-conscious consumers or high-tech gadget buyers. Brand-building initiatives: Companies looking to create a strong visual identity and differentiate themselves from competitors. Unboxing experiences: Direct-to-consumer brands that rely on unique packaging to impress customers and encourage social sharing. Industry compliance needs: Certain industries, such as pharmaceuticals, food, and electronics, require detailed labeling, child-resistant features, or protective inserts. ✅ Best for: Luxury retail, cosmetics, premium electronics, craft food, and specialized medical packaging. 🚨 Limitations: Higher costs, longer production times, and potential inventory management challenges. How to Decide Between Generic and Tailored Packaging When choosing between generic and tailored packaging, consider the following: Factor Generic Packaging Tailored Packaging Cost Lower, mass-produced Higher due to customization Branding Minimal, neutral Strong, highly customized Customer Experience Standard Engaging, premium feel Production Time Faster Longer due to customization Target Audience Broad market Specific niche or luxury segment Logistics & Storage Easier to manage More complex inventory Final Thoughts: Choosing the Right Packaging Strategy The decision between generic and tailored packaging depends on your business goals, budget, and target market. Generic packaging is cost-effective and practical for mass-market products, while tailored packaging creates brand differentiation and enhances customer experience. Need help deciding on the right packaging approach? Contact Brown Packaging today to explore customized solutions that align with your business strategy. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When selecting foam materials for packaging, polyethylene foam (PE) and polyurethane foam (PU) are two popular choices. While both offer protection and cushioning, their properties, applications, and advantages differ significantly. Understanding these differences will help you make an informed decision for your specific packaging needs. What is Polyethylene Foam? Polyethylene foam, or PE foam, is a lightweight and cost-effective material known for its flexibility and good insulation properties. Commonly used in packaging, PE foam provides cushioning, void fill, and surface protection for delicate items. Common Applications: Cushioning fragile items: Electronics, glassware, and delicate goods during shipping. Surface protection: Preventing scratches on furniture or appliances during storage or transport. Void fill: Filling empty spaces in packages to secure products. Customizations: Flame retardants for fire resistance. UV stabilizers to prevent degradation from sunlight exposure. Anti-static agents to protect sensitive electronic components. What is Polyurethane Foam? Polyurethane foam, or PU foam, is a more durable and versatile material compared to polyethylene foam. It offers excellent insulation, water resistance, and chemical resistance, making it suitable for more demanding applications. Common Applications: Industrial packaging: Protecting heavy equipment, automotive parts, and machinery. Impact protection: Absorbing vibration and shock during transportation. Insulation: Used in construction for thermal and sound insulation. Customizations: Colorants for aesthetic purposes. Flame retardants for enhanced safety. UV stabilizers for durability under sun exposure. Key Advantages and Disadvantages Advantages of Polyethylene Foam: Cost-Effective: Lower cost compared to PU foam. Lightweight: Ideal for reducing shipping weight. Flexible: Easily cut or shaped for various packaging needs. Good Insulation: Protects against temperature changes. Disadvantages of Polyethylene Foam: Lower Durability: Less resistant to water, chemicals, and impact. UV Degradation: Can deteriorate over time with sunlight exposure. Advantages of Polyurethane Foam: Durability: Withstands repeated use and tough conditions. Resistance: Protects against water, chemicals, and impact. Versatility: Suitable for a wide range of applications. Shock Absorption: Superior protection for heavier items. Disadvantages of Polyurethane Foam: Higher Cost: More expensive than PE foam. Density: Heavier and less flexible, limiting its use in certain applications. Sustainability Considerations Neither polyethylene nor polyurethane foam is biodegradable. Both materials take hundreds of years to decompose and can contribute to environmental pollution if not properly disposed of. However, polyethylene foam is more commonly recycled due to its lower density and easier handling during the recycling process. How to Choose Between PE and PU Foam Selecting the right foam depends on your specific needs: Cost Sensitivity:Choose polyethylene foam if budget constraints are a primary concern. Durability Needs:Use polyurethane foam for applications requiring resistance to water, chemicals, or rough handling. Product Weight:For lightweight items, PE foam is ideal. For heavy or fragile items, PU foam provides superior protection. Environmental Exposure:Consider PE foam for indoor storage or applications with minimal exposure to moisture or chemicals. Opt for PU foam for outdoor or industrial use. Conclusion Both polyethylene and polyurethane foams have unique strengths, making them suitable for different packaging needs. By understanding the properties and applications of each material, you can choose the one that best meets your requirements. If you’re looking for customized foam solutions, contact Brown Packaging today to explore our range of PE and PU foam options tailored to your needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Foam Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts