Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

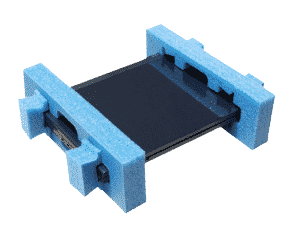

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

In the competitive retail landscape, creating a sense of urgency through Point of Purchase (POP) displays can significantly boost impulse buying and drive quick sales decisions. This blog explores effective strategies to harness the power of urgency in POP displays, helping retailers turn casual browsers into committed buyers. Understanding the Psychology of Urgency Urgency compels action. It taps into a consumer’s fear of missing out (FOMO) on a good deal, a new product, or a limited-time offer. The right use of urgency in a POP display can make the difference between a shopper walking by and one stopping to make a purchase. It’s about creating an irresistible offer that feels too good to pass up. Key Strategies to Create Urgency Limited-Time Offers Highlighting that a special offer is available for a limited time is a classic and effective way to create urgency. Use countdown timers or dates clearly stating when the promotion ends. This can be particularly effective during holiday sales, back-to-school seasons, or any other time-sensitive shopping periods. Limited Quantities Available Displaying messages like “While Supplies Last” or “Limited Stock” can drive home the urgency of purchasing before it’s too late. This strategy works well for products known to be popular or for newly released items that are expected to sell out quickly. Exclusive Products Featuring products that are exclusive to your store or available only for a limited period can also create urgency. Shoppers are more likely to make on-the-spot purchases if they believe they’re getting something unique or hard to find elsewhere. Flash Sales Utilize POP displays to promote flash sales, where products are available at a discount for a short period. This not only creates urgency but also adds an element of excitement to the shopping experience. Seasonal and Event-Driven Promotions Aligning POP displays with ongoing events or seasons can leverage existing consumer excitement and a natural sense of urgency. For example, a POP display with a “Back to School Sale Ends Soon!” message during the late summer effectively targets parents and students looking to complete their shopping in time. Design Elements That Enhance Urgency Bold and Clear Messaging Your urgency message should be the most prominent part of the display. Use large fonts, bold colors, and direct language to ensure the message is easily seen and understood from a distance. Visual Cues Use visual cues such as arrows or borders to draw attention directly to the urgency message. Bright colors like red or orange are often associated with urgency and can be very effective. Strategic Placement Place urgent POP displays at high-traffic areas or decision points within the store, such as near the checkout lanes or at the end of aisles. The more eyes on your urgent message, the better. Use of Technology Incorporating digital elements into your POP displays can make updating urgency messages more dynamic and timely. Digital screens can show changing countdowns, flash sale times, or instantly update stock levels to reflect scarcity. How to Create Effective Bundles Creating successful bundle packages requires careful planning and consideration. Here are some steps to guide you: Understand Your Audience: Start by understanding your target audience’s needs and preferences. What products or services are they likely to buy together? What problems can your bundles solve for them? Choose Complementary Products: Select products that naturally complement each other. They should enhance the value of the bundle and make sense to the customer. For example, a camera bundle could include lenses, a tripod, and a camera bag. Pricing Strategy: Determine the pricing strategy for your bundles. Typically, bundles are priced lower than the total cost of purchasing each item separately, offering customers a discount. However, ensure that your pricing still allows for a reasonable profit margin. Packaging Design: Invest in attractive and informative packaging design. The packaging should clearly communicate what’s included in the bundle and its value proposition. High-quality packaging enhances the perceived value of the bundle. Marketing and Promotion: Promote your bundles through various marketing channels, both online and offline. Highlight the benefits of purchasing the bundle, such as cost savings or convenience. Use visuals and descriptions that resonate with your target audience. Monitor and Adjust: Track the performance of your bundles. Analyze sales data, customer feedback, and return on investment. Make adjustments as needed to optimize your bundle offerings. Conclusion Creating a sense of urgency with POP displays is a potent strategy to accelerate decision-making and increase sales. By combining psychological triggers with strategic design and placement, retailers can effectively motivate customers to act quickly, increasing both customer engagement and profitability. Effective urgency strategies make the shopping experience exciting and rewarding, encouraging customers to make immediate purchases and potentially return for more. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

In e-commerce, packaging plays a crucial role in protecting products, creating a memorable unboxing experience, and building brand loyalty. Within packaging, there are different layers, with primary packaging being one of the most important. It is the first layer of protection directly surrounding the product, and it’s essential in safeguarding items and shaping customer perceptions. This blog will break down the concept of primary packaging in e-commerce, its functions, and why it matters for your business. What is Primary Packaging? Primary packaging refers to the material that is in direct contact with the product. It’s the first level of packaging that holds, protects, and contains the product itself. In many cases, it is the packaging that consumers interact with first when they open a package. Examples of primary packaging in e-commerce include: The bottle that holds liquid products like shampoos or lotions. The box that contains electronics, like a smartphone or a camera. The pouch that holds food items, such as coffee beans or snacks. In contrast, secondary packaging refers to the outer materials used for protection or grouping during shipping (such as the shipping box or mailer), while tertiary packaging is used for bulk handling and transportation (like pallets or larger boxes). Functions of Primary Packaging in E-Commerce Product Protection: The most essential role of primary packaging is to protect the product. It serves as a barrier against contamination, breakage, and external damage, ensuring that the product reaches the customer intact. For example, a glass bottle of perfume is encased in its primary packaging to shield it from damage and spills during transit. Branding and Marketing: Primary packaging is often the face of your brand. It is the first thing the customer sees and interacts with, making it a critical touchpoint for branding and marketing. Custom-designed packaging with logos, vibrant colors, or eye-catching graphics creates a memorable customer experience, differentiates your product from competitors, and reinforces brand identity. Information Delivery: Primary packaging provides essential information about the product, including product descriptions, ingredients, instructions for use, and expiration dates. For instance, a food package will typically include nutritional information and preparation instructions, making it easier for customers to use the product correctly. Customer Experience and Engagement: In e-commerce, where customers cannot physically inspect the product before purchasing, the unboxing experience becomes an essential part of customer engagement. Well-designed primary packaging enhances this experience, creating a sense of anticipation and satisfaction when customers receive their items. A memorable unboxing can lead to customer loyalty and even social media sharing. Why Primary Packaging Matters in E-Commerce Protects During Shipping In e-commerce, products are subject to more handling than traditional retail. Packages can be dropped, stacked, or mishandled during transit. Primary packaging needs to be durable enough to protect the product throughout this journey. Without effective primary packaging, products can arrive damaged, leading to returns, refunds, and dissatisfied customers. Influences Buying Decisions Primary packaging often influences customers’ purchase decisions. In e-commerce, product images and descriptions play a huge role, but once the item arrives, the physical packaging must meet the expectations set online. If the packaging is attractive, practical, and functional, it enhances the overall perception of the product. Creates Brand Loyalty Memorable and well-designed primary packaging adds to the unboxing experience and leaves a lasting impression on customers. When the packaging feels premium or reflects the company’s values (such as using eco-friendly materials), customers are more likely to remember the brand and make repeat purchases. Sustainability Matters As sustainability becomes a critical factor for consumers, brands are increasingly focusing on eco-friendly primary packaging options. By using recyclable or compostable materials, businesses not only protect their products but also align with consumer preferences for environmentally friendly packaging. This reduces environmental impact and enhances the brand’s reputation. Examples of Effective Primary Packaging in E-Commerce Cosmetics and Beauty Products: Primary packaging for beauty products, like lipstick tubes or foundation bottles, is designed to protect delicate formulations while offering a luxurious appearance. High-quality materials and aesthetically pleasing designs add to the product’s perceived value. Food and Beverage: Pouches or vacuum-sealed bags are often used for perishable items like coffee or snacks, preserving freshness and protecting the product from external factors like moisture and air. Electronics: Smartphones or headphones are housed in secure, often sleek boxes designed not only to protect against damage but also to enhance the unboxing experience. These boxes may include foam inserts for added protection and premium branding. Conclusion Primary packaging is a critical element in e-commerce packaging strategies. It plays an essential role in protecting the product, enhancing customer experiences, and strengthening brand identity. E-commerce businesses that invest in high-quality, sustainable, and well-designed primary packaging are more likely to see satisfied customers, lower return rates, and increased brand loyalty. If you’re interested in ecommerce packaging and/or primary packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Ecommerce Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging plays a crucial role in safeguarding products from various hazards that can compromise their quality, safety, and integrity. From the manufacturing floor to the store shelves and throughout the supply chain, products face several risks that can damage or spoil them if not properly addressed. In this blog, we will explore 7 of the biggest hazards to packaging and how to mitigate them effectively. Physical Impact Moisture and Humidity Temperature Fluctuations Contamination Tampering and Theft UV and Light Exposure Oxygen and Air Exposure Physical Impact Impact during Handling and Transport: Products often endure a series of impacts during handling and transportation. They may be dropped, bumped, or stacked under heavy loads, which can result in physical damage. To mitigate this hazard: Choose durable packaging materials that can withstand external pressure. Use cushioning materials like bubble wrap, foam, or corrugated inserts to protect fragile items. Ensure proper stacking and handling instructions for products during transit. Moisture and Humidity Exposure to Moisture: Exposure to moisture and humidity can lead to product spoilage, mold growth, and label deterioration. Common sources of moisture include condensation, humidity, or exposure to rain. To protect against moisture: Use moisture-resistant packaging materials, such as laminated films or barrier coatings. Include desiccants or humidity control products inside the packaging. Store products in a controlled environment with proper ventilation and dehumidification. Temperature Fluctuations Temperature Extremes: Extreme temperatures, both high and low, can adversely affect product quality and shelf life. Frozen or overheated products can spoil, change texture, or lose flavor. To mitigate temperature-related hazards: Utilize insulated packaging or temperature-controlled containers when necessary. Follow recommended storage and transportation temperature guidelines. Consider phase-change materials or gel packs for temperature-sensitive items. Contamination External Contaminants: Products can be exposed to external contaminants such as dust, dirt, and chemicals, leading to contamination risks. To minimize contamination hazards: Choose packaging materials that offer a protective barrier against external contaminants. Implement good manufacturing practices (GMP) and hygiene protocols during production and packaging. Regularly clean packaging equipment and storage areas. Tampering and Theft Tampering and Theft Prevention: Tampering and theft are serious concerns, especially for food and pharmaceutical products. Tampering can lead to safety risks, while theft results in financial losses. To prevent tampering and theft: Implement tamper-evident packaging features like shrink bands, breakable seals, or tear strips. Use security labels that leave a visible mark when removed. Employ serialization and track-and-trace systems to monitor product movement. UV and Light Exposure UV and Light Damage: Exposure to ultraviolet (UV) and visible light can cause product degradation, discoloration, and loss of quality. This is particularly relevant for light-sensitive items like pharmaceuticals and certain food products. To counter UV and light exposure hazards: Use opaque or UV-resistant packaging materials. Consider tinted or amber containers for light-sensitive items. Store products away from direct sunlight or fluorescent lighting. Oxygen and Air Exposure Oxygen and Oxidation: Certain products, such as perishable foods, pharmaceuticals, and sensitive chemicals, can deteriorate when exposed to oxygen. Oxygen can lead to oxidation, spoilage, or chemical reactions. To minimize oxygen exposure: Utilize oxygen barrier packaging materials to restrict oxygen permeation. Vacuum-seal products to remove air from the package. Implement nitrogen flushing or gas flushing to displace oxygen. By addressing these major hazards to packaging, you can enhance the protection of your products throughout their journey from production to the hands of consumers. Tailoring your packaging solutions to specific product characteristics and understanding the risks involved is essential for maintaining product quality, safety, and customer satisfaction. If you are interested in safe and proper packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and specifications available, it can be challenging to decide which is best suited for your products. This guide breaks down the key differences between board options, including thickness, weight, color (kraft vs. white vs. Kemi), and strength (stacking vs. bursting), to help you make informed choices. Key Factors to Consider When Choosing Board Options Thickness and Weight The thickness and weight of your board directly impact the durability and cost of your packaging. Single-Wall Corrugated: Ideal for lightweight products; cost-effective and space-saving. Double-Wall Corrugated: Provides additional durability for heavier or more fragile items. Triple-Wall Corrugated: Offers maximum strength for industrial or bulk shipments. Weight Classifications (measured in pounds per thousand square feet): 26 ECT (Edge Crush Test): Common for lightweight items. 32 ECT: Standard for shipping boxes. 44 ECT: Provides added strength for heavier goods. Pro Tip: Higher ECT ratings or thicker boards are better for products requiring long shipping routes or frequent handling. Kraft vs. White vs. Kemi The color and surface type of your board affect its appearance, branding potential, and environmental impact. Kraft Board: Natural, unbleached brown board. Eco-friendly and cost-effective. Popular for brands emphasizing sustainability. White Board: Provides a clean, polished look. Ideal for high-quality printing and branding. Slightly higher cost due to added processing. Kemi Board: A premium option with a clay-coated surface. Superior for high-quality graphics and moisture resistance. Often used in food packaging or high-end retail boxes. Pro Tip: Kraft is a great choice for eco-conscious brands, while white or Kemi boards work best for visually appealing, printed designs. Stacking Strength vs. Bursting Strength Board strength is measured in two key ways, and understanding the difference is crucial for selecting the right material for your needs. Stacking Strength (Edge Crush Test – ECT): Measures a box’s ability to withstand compression when stacked. Ideal for vertical storage or heavy stacking in transit. Bursting Strength (Mullen Test): Measures resistance to punctures or tears. Better for products that might face rough handling or impact during shipping. Pro Tip: If you’re shipping lightweight items in large quantities, prioritize stacking strength. For fragile or high-value items, bursting strength is more critical. Comparing Board Options Feature Single-Wall Corrugated Double-Wall Corrugated Triple-Wall Corrugated Thickness Light Medium Heavy Weight Capacity Up to 65 lbs 65–95 lbs 95–300 lbs Common Use Cases Apparel, lightweight items Electronics, fragile goods Industrial equipment, bulk items Cost Low Medium High Selecting the Right Board for Your Needs Product Protection Needs For lightweight products: Single-wall corrugated with 32 ECT. For heavy or fragile items: Double-wall corrugated or higher ECT. For high-value items: Triple-wall corrugated or Kemi board with enhanced burst strength. Branding and Visual Appeal For a natural look: Kraft board. For premium branding: White or Kemi boards with gloss or matte finishes. Environmental Considerations For eco-conscious brands: Kraft board with recycled content. For durability with sustainability: Boards with high post-consumer recycled content. FAQs About Board Options Stacking strength measures a box’s ability to withstand vertical pressure, while bursting strength evaluates its resistance to punctures or tears. When should I choose Kemi over white or kraft? Kemi board is ideal for applications requiring superior graphics and moisture resistance, such as food or luxury packaging. How do I balance cost and durability? Consider your product’s weight and shipping needs. Single-wall corrugated is cost-effective for lightweight items, while double-wall is better for heavier goods. Conclusion Choosing the right board option involves balancing your product’s protection needs, branding goals, and budget. Whether you’re deciding between kraft and white or evaluating strength requirements, understanding these factors will help you select the perfect packaging solution. Need expert advice on board materials? Contact us today for tailored recommendations that meet your durability, branding, and budget goals! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Launching a product or redesigning packaging can be a significant investment. To minimize risk and gather actionable insights, small packaging runs are a smart way to test the market. This approach allows businesses to gauge consumer reactions, refine designs, and optimize functionality before committing to large-scale production. Here’s how small packaging runs can drive success and why digital production is often the ideal method for this purpose. Why Test with Small Packaging Runs? Minimized RiskBy starting with a small batch, businesses can test packaging concepts without a large financial commitment. This ensures that only well-received designs move forward to full-scale production. Market ValidationTesting in the real world—through focus groups, pop-up shops, or limited releases—provides valuable feedback on packaging design, labeling, and usability. This helps identify what resonates with your audience. Iterative DesignSmall runs allow for adjustments and multiple rounds of testing. Based on feedback, businesses can tweak designs, materials, or messaging to create a more polished final product. Cost-Effective ExperimentationCompared to mass production, small runs are significantly less expensive. This makes it possible to try out multiple designs or features without incurring substantial costs. Why Digital Production is Ideal for Small Runs No Setup CostsTraditional printing methods, like offset printing, require expensive setup processes such as plate creation. Digital printing eliminates these costs, making it cost-efficient for small batches. Faster TurnaroundDigital production enables quick printing and delivery, perfect for tight deadlines or rapid testing cycles. High-Quality OutputModern digital printing delivers sharp, vibrant results, ensuring test packaging looks professional and consistent with final production runs. Flexibility With digital production, you can easily modify designs between runs to test different elements like colors, layouts, or messaging. Key Considerations for Effective Testing Sample Size: Ensure your test batch is large enough to yield statistically significant results. Data Collection: Use multiple methods like online surveys, in-person interviews, or sales performance data to gather insights. Adaptability: Be prepared to adjust your design based on feedback to ensure your packaging aligns with customer expectations. Benefits of Testing with Small Runs Advantage Explanation Cost Savings Avoid overproduction and reduce the risk of investing in a design that doesn’t work. Customer Insights Direct feedback helps identify strengths and weaknesses in your packaging design. Agility Quickly implement changes without the delay or expense of large-scale production. Reduced Environmental Impact Produce only what you need, minimizing waste and resources. Real-World Application: Split Testing for Packaging Split testing, or A/B testing, is a powerful strategy for packaging design. By creating two or more versions of your packaging, you can compare their performance in the marketplace. Examples include: Testing different color schemes or logos. Comparing headline copy or product descriptions. Experimenting with eco-friendly materials versus traditional ones. This iterative process ensures your packaging is always optimized for customer appeal and performance. Conclusion Testing the market with small packaging runs is a low-risk, high-reward strategy for businesses looking to launch new products or redesign packaging. By leveraging digital production for these runs, you gain the flexibility to experiment, refine, and validate designs before committing to large-scale production. Ready to test your packaging? Contact us today to explore digital production solutions tailored to your small-run needs! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts