Home » How to Structurally Design Your Corrugated Box

How to Structurally Design Your Corrugated Box

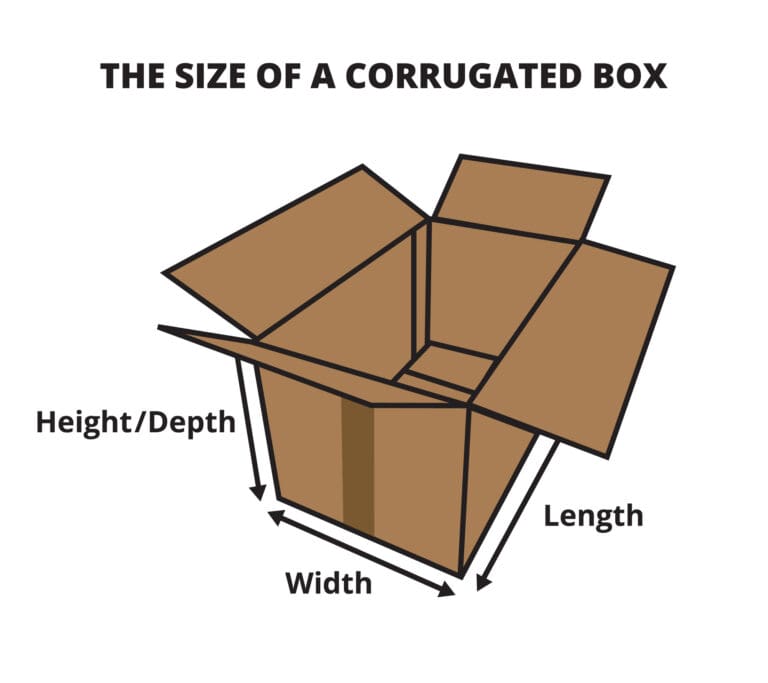

Structurally designing your corrugated box involves understanding the specific requirements of your product and applying principles of material science and engineering to ensure optimal protection, efficiency, and cost-effectiveness. This process requires careful consideration of the box’s dimensions, material grade, flute type, and the intended use to create a packaging solution that meets both logistical and aesthetic needs.

Understanding the Basics of Corrugated Boxes

Before diving into the design process, it’s important to grasp the fundamental components of a corrugated box:

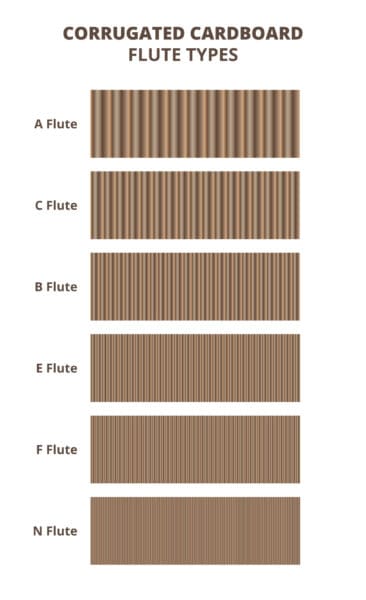

- Fluting: The wavy layer of corrugated paper that provides cushioning and strength. The size, type and the material of the flute affect the box’s compression strength, stacking strength, and crush resistance.

- Linerboards: Flat sheets of paper that sandwich the fluting, contributing to the box’s durability and structural integrity.

- Box Types: Common configurations include the Regular Slotted Container (RSC), Full Overlap (FOL), and Die-Cut designs, each offering different benefits in terms of protection and assembly efficiency.

Step 1: Assess Product Requirements

Start by evaluating the weight, dimensions, and fragility of the product. Consider any additional space needed for internal packaging materials like bubble wrap or foam inserts, which provide extra protection for delicate items. This assessment will guide the choice of box size and strength needed to ensure safe transport and storage.

Step 2: Select Material and Flute Type

Choose the appropriate material grade and flute type based on the product’s weight and the level of protection required. For lightweight items, a single-wall box with smaller flutes like B or C may suffice. Heavier or more fragile items may require double-wall or triple-wall boxes with larger flutes like A or BC for increased cushioning and strength. The Edge Crush Test (ECT) rating of the cardboard is a critical factor here, indicating the box’s ability to withstand external pressures.

Step 3: Design for Efficiency and Sustainability

Efficiency in packaging not only reduces material costs but also minimizes waste, contributing to sustainability. Design your box to fit your product snugly while allowing for minimal extra packaging material. Consider using recyclable materials and designing for ease of recycling after use, such as avoiding mixed materials that are difficult to separate.

Step 4: Prototype and Test

Once the initial design is established, create a prototype of your box. This allows for hands-on testing to ensure the box meets your requirements in terms of size, strength, and functionality. Conduct tests that mimic real-world handling, shipping, and stacking scenarios to identify any structural weaknesses or design flaws.

Step 5: Customization and Branding

Customization isn’t just about aesthetics; it can also enhance the box’s structural integrity. For example, die-cut inserts not only secure products within the box but also add rigidity to the structure. Use the exterior for branding, but ensure that any printing or customization does not compromise the box’s strength.

Step 6: Iterate Based on Feedback

Use feedback from the testing phase to refine your design. This may involve adjusting dimensions, changing the flute type, or reevaluating the material grade. Iteration is a crucial step in optimizing the design for both protection and cost.

Conclusion

Structurally designing a corrugated box is a detailed process that blends science, engineering, and aesthetics. It requires a deep understanding of the product needs, material properties, and the logistical demands of shipping and handling. By following these steps and focusing on both function and form, you can develop a corrugated box that not only protects your product but also enhances your brand’s presentation and sustainability efforts.

If you are interested in custom structurally designed corrugated boxes, then partner with Brown Packaging today to get started.

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers predict failures, validate material changes,

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » How to Structurally Design Your Corrugated Box