Home » How to Handle Packaging Price Increases

How to Handle Packaging Price Increases

Packaging prices don’t always stay still. Whether due to raw material costs, tariffs, labor increases, or supply chain shifts, price hikes can hit unexpectedly—and impact your entire product margin. If you’re a buyer or procurement lead, knowing how to respond is critical.

Should you pass the cost to your customers? Change your packaging? Negotiate with suppliers? Here’s how to make the smartest move for your business.

Understand Why the Price Increased

Before reacting, ask your supplier for transparency. Common reasons include:

- Material costs (paperboard, plastic, corrugate)

- Freight and fuel surcharges

- Labor increases

- Tariffs or import duties

- Order volume changes

Knowing the root cause helps you decide whether it’s a temporary spike or a long-term shift—and whether it’s worth absorbing or working around.

Review Your Packaging Spend in Detail

Instead of focusing only on the total cost increase, break it down by:

- Cost per unit

- Cost per SKU

- Cost relative to your product margin

This gives you a better sense of how much it actually affects your bottom line—and which products are most impacted.

Talk to Your Supplier About Options

Don’t assume the quoted increase is final. You may be able to:

- Adjust your order quantity for better volume pricing

- Modify materials to reduce cost without changing function

- Consolidate SKUs to simplify production

- Bundle packaging items for savings on combined runs

A good supplier will work with you to find cost-saving adjustments that don’t sacrifice quality.

Reevaluate Your Product Pricing

If the increase is significant and widespread, it may be time to adjust your product pricing—but do it strategically.

- Small increases (under 5%) can often be absorbed with better packaging design or minor cost shifts elsewhere.

- Larger increases may require pricing strategy updates, especially if your competitors are facing the same issues.

- Pairing a price increase with added value (e.g., sustainability, upgraded packaging, bonus content) helps ease customer pushback.

If your product is priced too tightly, this could be a good time to revisit margins and ensure you’re leaving room for volatility.

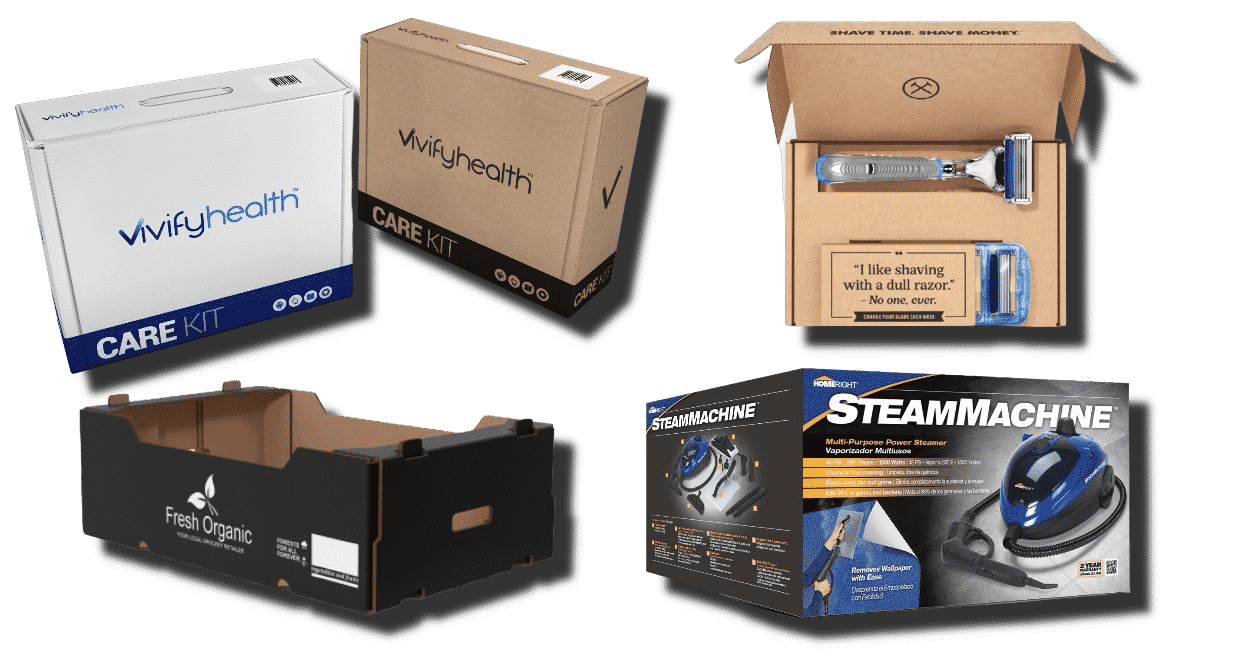

Consider a Packaging Redesign

Sometimes the best solution is a smarter box. Packaging engineers can help you:

- Reduce excess material or void fill

- Switch to more efficient structures

- Use lighter board grades without losing protection

- Combine inner and outer packaging functions

These changes can offset increased costs and even improve the customer experience in the process.

Final Thoughts

Packaging price increases are part of doing business—but how you respond determines whether you lose margin or find opportunity. By understanding the cause, reviewing your options, and thinking long-term, you can protect your brand, your product, and your profit.

Need help adjusting your packaging strategy without sacrificing performance?

We’ll help you find smarter solutions that keep costs down and customer experience strong.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » How to Handle Packaging Price Increases