Home » Holiday Fulfillment: Why Early Planning Matters

Holiday Fulfillment: Why Early Planning Matters

Why Holiday Fulfillment Demands Precision

The holiday season introduces a unique set of pressures across the packaging and supply chain landscape—especially for businesses managing kitting, packouts, display builds, or co-packing services. Between condensed retail calendars, last-minute promotional pushes, and compressed logistics windows, fulfillment must shift from a support function to a strategic asset. For manufacturers, brand owners, and retailers, the ability to deliver complete, shelf-ready packaging at scale is the difference between capturing seasonal revenue or missing key market opportunities.

What makes this time so complex isn’t just volume—it’s configuration. Packaging fulfillment during the holidays often involves:

- Multi-SKU kitting (e.g., bundling accessories with electronics)

- Retail display assembly (quarter pallets, PDQs, club store displays)

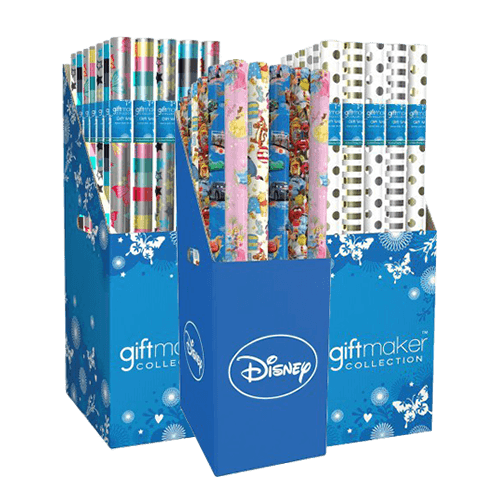

- Gift pack co-packaging (personal care sets, food samplers)

- Custom print alignment across SKUs and inserts

- Retailer-specific compliance (labeling, orientation, EDI, GTIN/UPC)

These tasks require a fulfillment partner that understands not just packaging mechanics, but retail logistics, promotional timing, and downstream handling constraints.

Lead Time Compression and Q4 Logistics Constraints

Planning for Q4 fulfillment can’t begin in Q4. By late September, most contract packagers and display fulfillment centers are already operating at or near capacity. Display board lead times stretch, labor is reallocated to high-volume clients, and transportation bottlenecks can ripple back through the supply chain. Businesses that haven’t secured fulfillment commitments by then risk:

- Extended production turnarounds

- Higher expedited freight costs

- Noncompliance with delivery windows

- Disruption to promotions tied to specific dates

Early planning ensures access to labor, materials, and floor space—especially critical for labor-intensive programs that involve manual assembly, complex sequencing, or rigid retailer routing guides.

Technical Considerations for Holiday Fulfillment Packaging

To optimize fulfillment packaging during peak season, businesses should evaluate technical performance across multiple areas:

- Packout efficiency: Design kits and displays with fulfillment-friendly construction (e.g., quick-fold cartons, drop-in inserts, common dimensions)

- Structural compatibility: Ensure inner packs, cartons, and trays can be packed quickly and securely without secondary rework

- Barcode and label clarity: Use pre-applied or inline printed labels for traceability, GTIN compliance, and retailer scan accuracy

- Shipping durability: Account for stacking, vibration, and mixed-freight environments to avoid rework due to damage in transit

- Vendor-managed inventory (VMI) compatibility: If operating under VMI or JIT models, ensure real-time fulfillment visibility and flexibility

The more technical precision built into the packaging, the less risk of costly repackaging, returns, or retail chargebacks during peak execution.

The Value of Full-Service Fulfillment Partners

Choosing a fulfillment partner who understands packaging, logistics, and compliance is essential. Brown Packaging offers integrated services that support holiday programs from structural design to floor-ready delivery, including:

- Custom corrugated and display builds

- Kitting and assembly

- Retail-ready palletization

- Labeling and barcoding

- Inventory staging and JIT release

- Retailer routing and compliance

By coordinating packaging execution with fulfillment from the start, brands can reduce lead times, avoid redundancies, and streamline promotional success.

Final Takeaway

Peak-season success isn’t about last-minute volume—it’s about early-stage precision. For any brand planning kitting, co-packing, or holiday display builds, the time to secure capacity, align specifications, and test packaging formats is now. By partnering with a fulfillment expert who understands the entire packaging lifecycle, you position your business to deliver seamlessly under pressure—while your competitors scramble to catch up.

Need holiday fulfillment support? Brown Packaging provides technical design, fulfillment coordination, and logistics solutions that scale. Let’s plan early and deliver with confidence.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Holiday Fulfillment: Why Early Planning Matters