Home » Foam Density Selection for Heavy vs. Light Products

Foam Density Selection for Heavy vs. Light Products

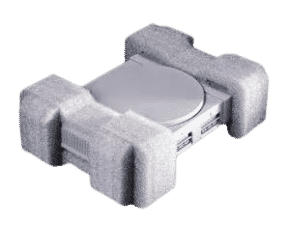

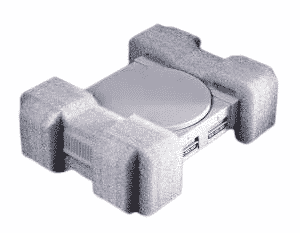

Choosing the right foam density isn’t about “soft” versus “hard” — it’s about controlling shock transmission and matching the foam’s cushioning curve to the product’s fragility. Using the wrong density can cause more damage than using no foam at all.

Understanding Foam Density

- Definition: Density is the mass per unit volume (lb/ft³ or kg/m³) and directly affects stiffness, energy absorption, and weight.

- Not the Same as Firmness: Firmness (indentation force deflection) can vary independently of density depending on foam chemistry.

How Density Affects Shock Absorption

- Low-Density Foam:

- Better for light, delicate products where over-compression could cause crushing.

- May bottom out under heavy loads, losing protection.

- High-Density Foam:

- Better for heavy items, spreading impact force over a longer deceleration period.

Can be too stiff for fragile, lightweight products, causing rebound shock.

Product Fragility

- For fragile electronics (fragility rating ~30–50 G), choose foam that keeps transmitted forces below the product limit.

For rugged machinery parts (~100+ G), higher density foam can provide adequate protection with minimal thickness.

Environmental Factors

- Temperature Sensitivity: Some foams stiffen in cold storage, increasing G-force transmission.

- Moisture Uptake: Certain foams lose energy absorption properties when saturated.

Testing and Standards

- ASTM D1596: Determines cushioning characteristics of packaging materials.

- ASTM D4168: Measures shock cushioning performance in simulated transit.

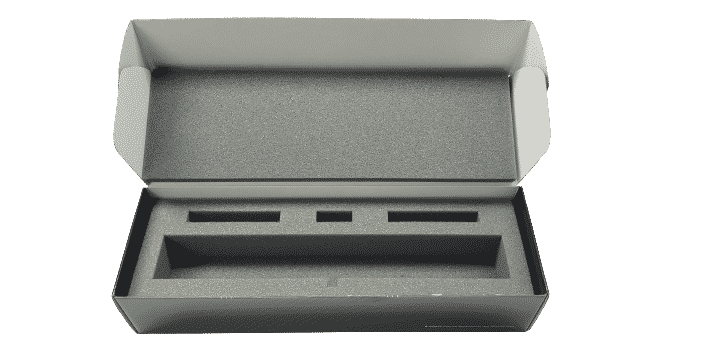

Best Practices for Selection

- Always test with actual product weight and packaging configuration.

- Avoid relying solely on density — evaluate density + cushioning curve together.

- Consider hybrid solutions, such as layering low- and high-density foams for mixed load shipments.

References

ASTM International. (2014). ASTM D1596-14: Standard test method for dynamic shock cushioning characteristics of packaging materials. ASTM International. https://www.astm.org/d1596-14.html

ASTM International. (2014). ASTM D4168-14: Standard test method for transmitting shock through packaging materials. ASTM International. https://www.astm.org/d4168-14.html

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers predict failures, validate material changes,

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » Foam Density Selection for Heavy vs. Light Products