Home » Designing Foam and Corrugated Hybrid Inserts

Designing Foam and Corrugated Hybrid Inserts

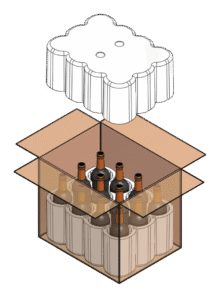

Foam-in-corrugated hybrid inserts combine the cushioning properties of foam with the structural rigidity of corrugated board, creating a packaging solution that is both protective and adaptable. This design approach is particularly useful in industries where precision fit and shock absorption are critical, such as electronics, medical devices, and high-value industrial components.

Why Combine Foam and Corrugated?

Corrugated offers structural stability, vertical stacking strength, and a printable surface for branding or instructions. Foam provides vibration dampening, energy absorption during impact, and surface protection against scratches or abrasions. When integrated, these materials address a broader range of performance requirements than either could alone.

Material Selection

The choice of foam type—such as polyethylene (PE), polyurethane (PU), or expanded polystyrene (EPS)—should be driven by product fragility, weight, and storage conditions. PE foam, for example, excels in repeated compression recovery, making it suitable for reusable inserts. Corrugated board grades (e.g., single-wall B-flute vs. double-wall BC-flute) must be matched to anticipated stacking loads and compression requirements.

Bonding Methods and Compatibility

Adhesive selection is critical. Water-based adhesives can warp corrugated under high humidity, while hot-melt options may degrade certain foam chemistries. Mechanical retention methods, such as die-cut lock tabs or slotted cavities, can reduce adhesive usage and improve recyclability.

Engineering Fit and Tolerance Control

Foam compression should be engineered to 10–30% deflection under typical product weight to balance retention and ease of removal. Corrugated cutouts must account for foam expansion and any dimensional variation due to manufacturing tolerances. Overly tight fits can cause stress concentrations, while loose fits reduce protection efficiency.

Shock and Vibration Performance

ASTM D1596 testing can determine the foam’s cushioning curve, ensuring the hybrid insert meets drop-test performance requirements. Corrugated structure should be verified under ASTM D642 compression testing to confirm stacking safety in transit and storage.

Sustainability Considerations

Designing with minimal adhesive, using water-based inks for print, and specifying recyclable PE foams can increase end-of-life recyclability. An emerging approach is designing separable components so the foam and corrugated can be easily disassembled for proper recycling streams.

References

American Society for Testing and Materials. (2019). ASTM D1596-14: Standard Test Method for Dynamic Shock Cushioning Characteristics of Packaging Material. https://doi.org/10.1520/D1596-14

American Society for Testing and Materials. (2015). ASTM D642-15: Standard Test Method for Determining Compressive Resistance of Shipping Containers. https://doi.org/10.1520/D0642-15

Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Kistler, S. F., & Schweizer, P. M. (Eds.). (2013). Liquid Film Coating: Scientific Principles and Their Technological Implications. Springer. https://doi.org/10.1007/978-94-011-4942-0

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Designing Foam and Corrugated Hybrid Inserts