Home » Custom Corrugated Box Trends for 2026

Custom Corrugated Box Trends for 2026

Why Custom Corrugated Boxes Remain a 2026 Essential

Custom corrugated boxes continue to be the most relied-on packaging solution for industries ranging from industrial manufacturing to ecommerce. But in 2026, the focus is shifting from basic box customization to engineered performance, material precision, and automation-ready design. Buyers are no longer just sourcing packaging—they’re optimizing it for speed, cost, and product protection.

Whether you’re buying corrugated boxes for shipping, retail display, or product kitting, here’s what to expect this year.

Structural Design Is Driving the New Definition of Custom

In 2026, “custom corrugated packaging” means more than just size and print—it’s about functional structure.

- Businesses are prioritizing right-size engineering to cut down on void fill, improve stacking, and reduce damage

- Popular designs like multi-depth RSCs, auto-lock bottoms, and dual-SKU shipper trays are growing

- Custom inserts and internal supports are being integrated into the box structure itself—not as separate packaging steps

If you’re shipping high-value or odd-shaped products, expect 2026 solutions to emphasize built-in protection and packaging efficiency.

Corrugated Material Selection Is More Technical Than Ever

Rising board costs and stricter sustainability requirements are reshaping how materials are specified.

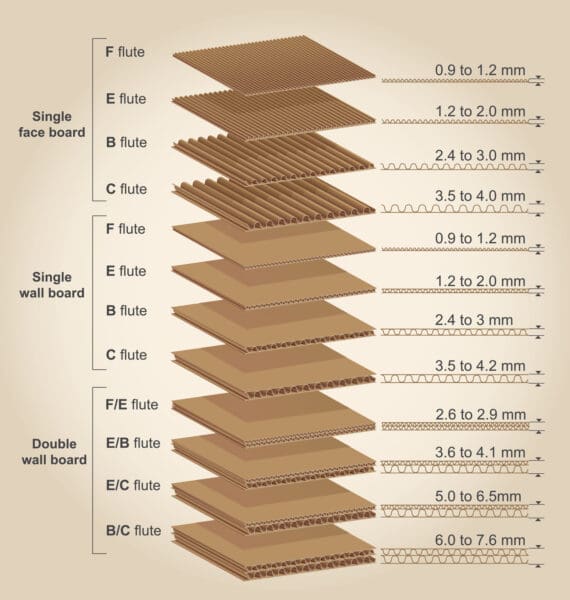

- Clients are now choosing corrugated by ECT, puncture rating, and flute profile, not just by thickness

- Recycled and virgin content blends are being optimized based on weight, moisture exposure, and destination

- Lighter-weight corrugated is being reinforced through design (edge wraps, folded ribs, etc.), not just thicker walls

This year, your corrugated box’s performance will come more from material science + structure than brute strength.

Automation Compatibility Is a Procurement Priority

Packaging that doesn’t run smoothly on automated lines is a liability. In 2026:

- Buyers are demanding machine-compatible corrugated formats, with tolerances that support automated erecting, loading, and sealing

- Expect growth in auto-bottom boxes, precise glue flap alignment, and barcode-friendly panel design

- Custom boxes are being designed in tandem with fulfillment processes—not retrofitted afterward

For high-volume shippers, compatibility with WMS and automation systems is now a core spec—not an afterthought.

Custom Corrugated Boxes Are Becoming Data-Driven Sustainability Tools

2026 sustainability goals are technical, not theoretical.

- Corrugated boxes are being selected for FSC or SFI certification, recyclability scores, and regional sourcing proximity

- Life cycle assessment (LCA) data is being requested by major retailers and procurement teams

- Minimalist branding, lighter flutes, and efficient structural design are all being used to cut carbon, not just cost

Sustainability is part of how your box is measured—so make sure it’s part of how it’s designed.

Built-In Branding, Not Just Printed Logos

While most custom corrugated boxes—especially RSC formats—still use single-color flexo print, more are evolving to support multi-SKU visibility, inventory control, and regulated handling.

- Expect wider use of label panels, QR codes, and internal printing for ease of returns and fulfillment

- High-end retail corrugated (especially for appliances or electronics) will see more use of digital or lithographic labels

- Structural design now plays a role in branding—form, function, and fit are part of how buyers perceive value

Your corrugated box is part of the product experience, even if it’s headed for a warehouse—not a retail shelf.

Conclusion: Corrugated in 2026 Is a Strategic Advantage

If you’re still buying boxes by the spec sheet, you’re missing opportunities to improve speed, reduce damage, and increase operational efficiency. In 2026, custom corrugated boxes are no longer just a container—they’re part of your business infrastructure.

Whether you’re focused on industrial logistics, subscription fulfillment, or protecting high-value goods, now is the time to reassess your packaging. Brown Packaging helps brands design fully customized corrugated solutions that align with your cost targets, sustainability goals, and logistics requirements.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Custom Corrugated Box Trends for 2026