Blogs

At Brown Packaging, we provide insightful content about the packaging industry to keep our clients, followers, and partners informed with the latest trends and accurate information. Our goal is to equip you with up-to-date knowledge that helps you stay ahead in the ever-evolving world of packaging.

Wine, the elixir of celebration and sophistication, demands packaging that not only safeguards its integrity but also reflects its prestige. Whether you’re a winery owner,

In the world of marketing, custom packaging has emerged as a powerful tool for brand differentiation and delivering unforgettable customer experiences. It’s more than just

When it comes to packaging solutions, selecting the appropriate type of box can significantly impact convenience, functionality, and the overall user experience. Two common options

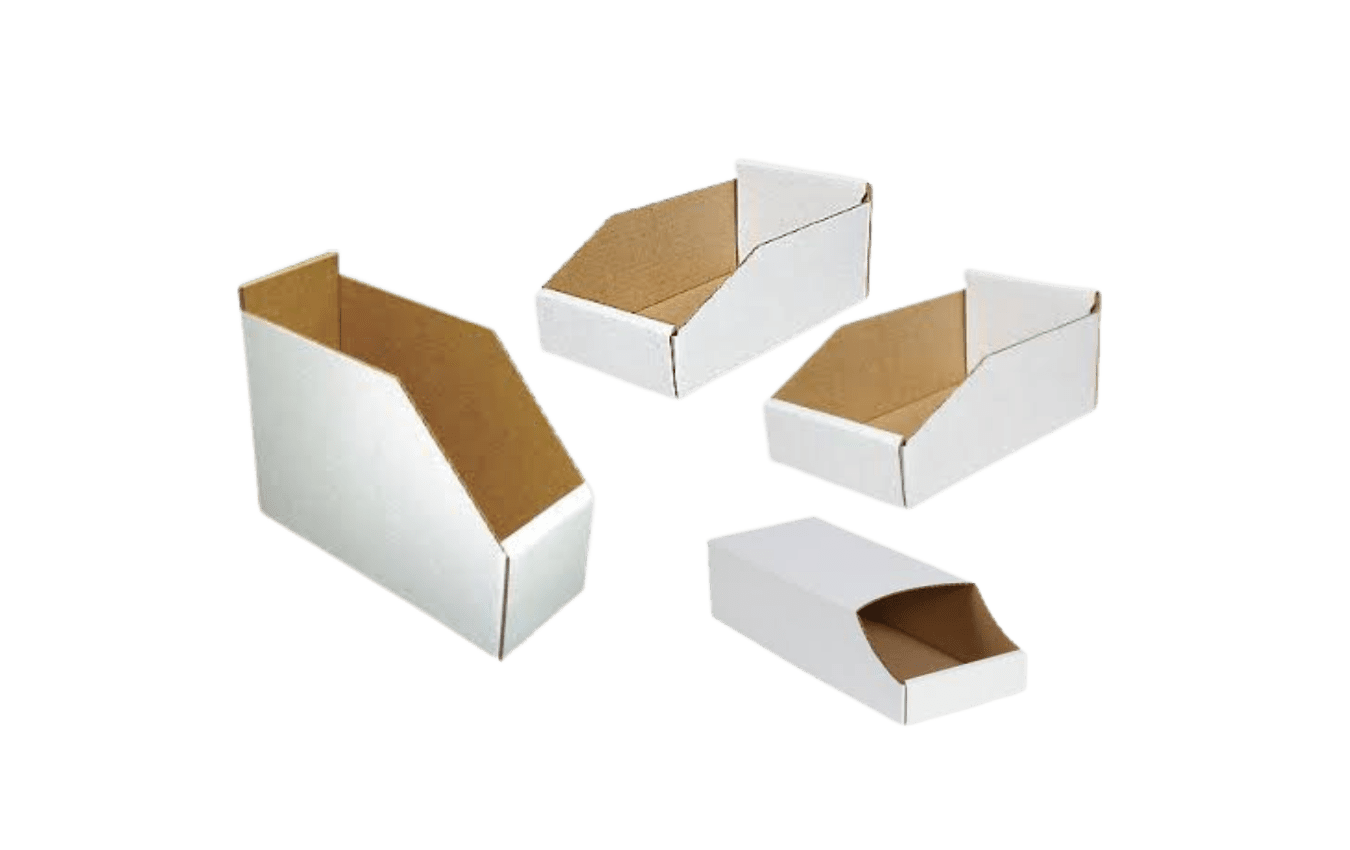

Corrugated bin boxes have become a staple in the retail industry, offering a myriad of benefits for both store owners and shoppers alike. At first

Packaging is more than just a means to protect and transport products. It is a powerful tool for brand recognition, customer engagement, and conveying product

Corrugated boxes have been a staple in packaging and shipping for decades, and they continue to play a crucial role in various industries. As we

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it

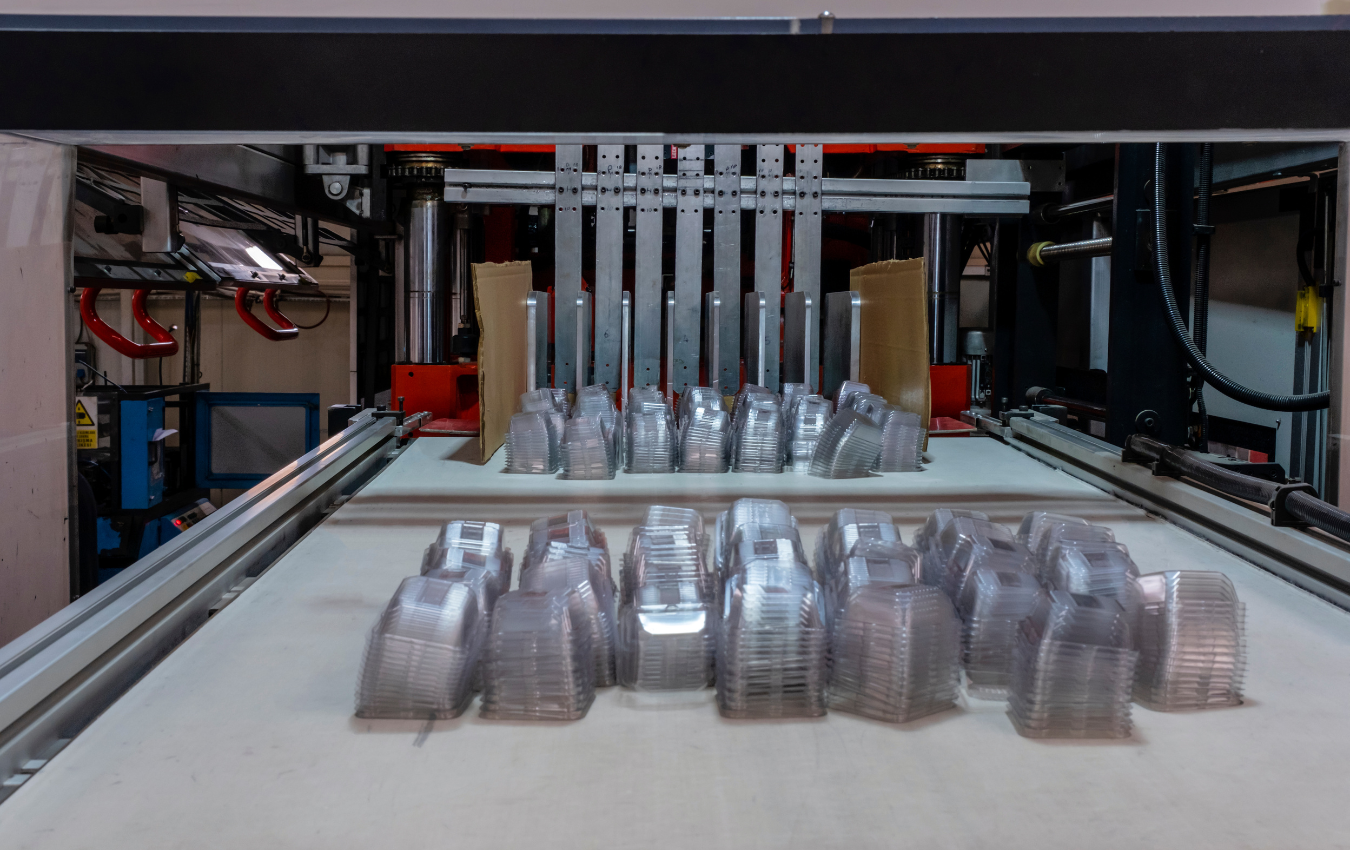

The world of packaging has seen tremendous innovation over the years. With the increasing emphasis on product safety, hygiene, sustainability, and overall aesthetic appeal, manufacturers

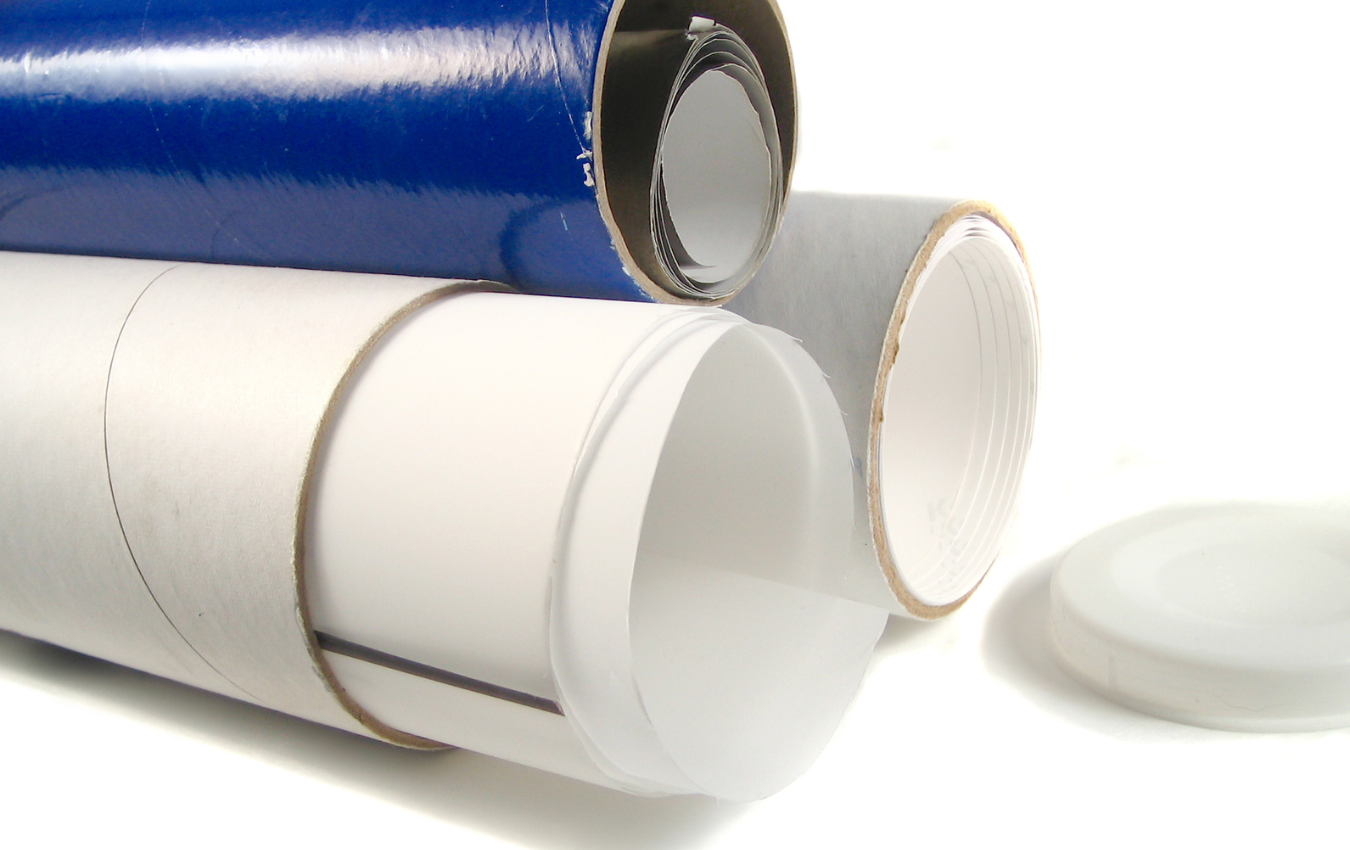

In today’s fast-paced world, one industry that keeps businesses and individuals connected is the shipping and mailing industry. An often overlooked but crucial component of

Corrugated bin boxes are indispensable in warehouses, retail spaces, and offices. They are designed to hold, organize, and transport items efficiently. However, to ensure safety

In the dynamic world of packaging, one must constantly innovate to maintain a competitive edge. As we move through 2024, custom pouch packaging is standing

When you think about product packaging, your mind probably jumps to traditional solutions like plastic containers, cans, or cardboard boxes. However, a dramatic shift is

In the dynamic and ever-evolving food industry, packaging plays a pivotal role in preserving the quality, safety, and freshness of products while also captivating consumers

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability

Storage solutions are essential for any business who wants to organize their space efficiently. One of the most effective and economical options are corrugated bin

In the current competitive retail landscape, the packaging of a product plays an increasingly significant role in customer decision-making. Brands are progressively realizing the power

The packaging industry has continuously evolved throughout history, striving to develop solutions that are practical, reliable, and cost-effective. Among these, mailing tubes have emerged as

Corrugated boxes play a vital role in the packaging industry, offering durability and versatility for shipping and storing various products. To ensure the safe transportation

Venture into a sizable retail store, roam the pathways of an expansive warehouse, or take a behind-the-scenes glance at a bustling e-commerce fulfillment center, and

With the rise in accidental medication ingestions by children each year, it has become increasingly important to implement child-resistant packaging. Among various packaging solutions, child-resistant

The world of packaging is an intricate system of components working together to ensure products reach consumers in pristine condition. Many packaging elements such as