Home » Best Packaging Strategy for Multi-SKU Pouches

Best Packaging Strategy for Multi-SKU Pouches

Multi-SKU product lines offer variety, but when it comes to packaging, they also create complexity. Whether you’re offering different flavors, sizes, formulas, or bundle combinations, choosing the right approach for packaging pouches across multiple SKUs is key to keeping things organized, cost-effective, and retail-ready.

In this blog, we break down the smartest ways to handle multi-SKU pouch packaging and what strategies can simplify your process while maximizing shelf appeal.

Why Multi-SKU Pouch Packaging Needs a Strategy

If your product line includes multiple variations—like a protein powder in four flavors, or snacks in ten varieties—you’ll likely be working with multiple pouch designs and potentially different sizes. Without a plan, this can lead to over-ordering, poor inventory control, mismatched branding, and increased lead times.

A strategic approach to multi-SKU pouch packaging helps you:

- Streamline production and inventory

- Maintain consistent branding across all variations

- Improve packaging efficiency for both retail and e-commerce

- Reduce waste and minimize packaging costs

Choose the Right Pouch Format for All SKUs

The first step is selecting a pouch format that can work across your entire SKU range. This simplifies your sourcing, design process, and shipping logistics.

Common formats that work well across SKUs:

- Stand-up pouches for shelf presence

- Flat pouches for sample sizes or low-profile products

- Zipper pouches for resealability and convenience

- Printed roll stock if you need to automate pouch forming in-house

Sticking to a single pouch style for all SKUs—just with design changes—makes production and fulfillment smoother.

Leverage Digital Printing for Design Flexibility

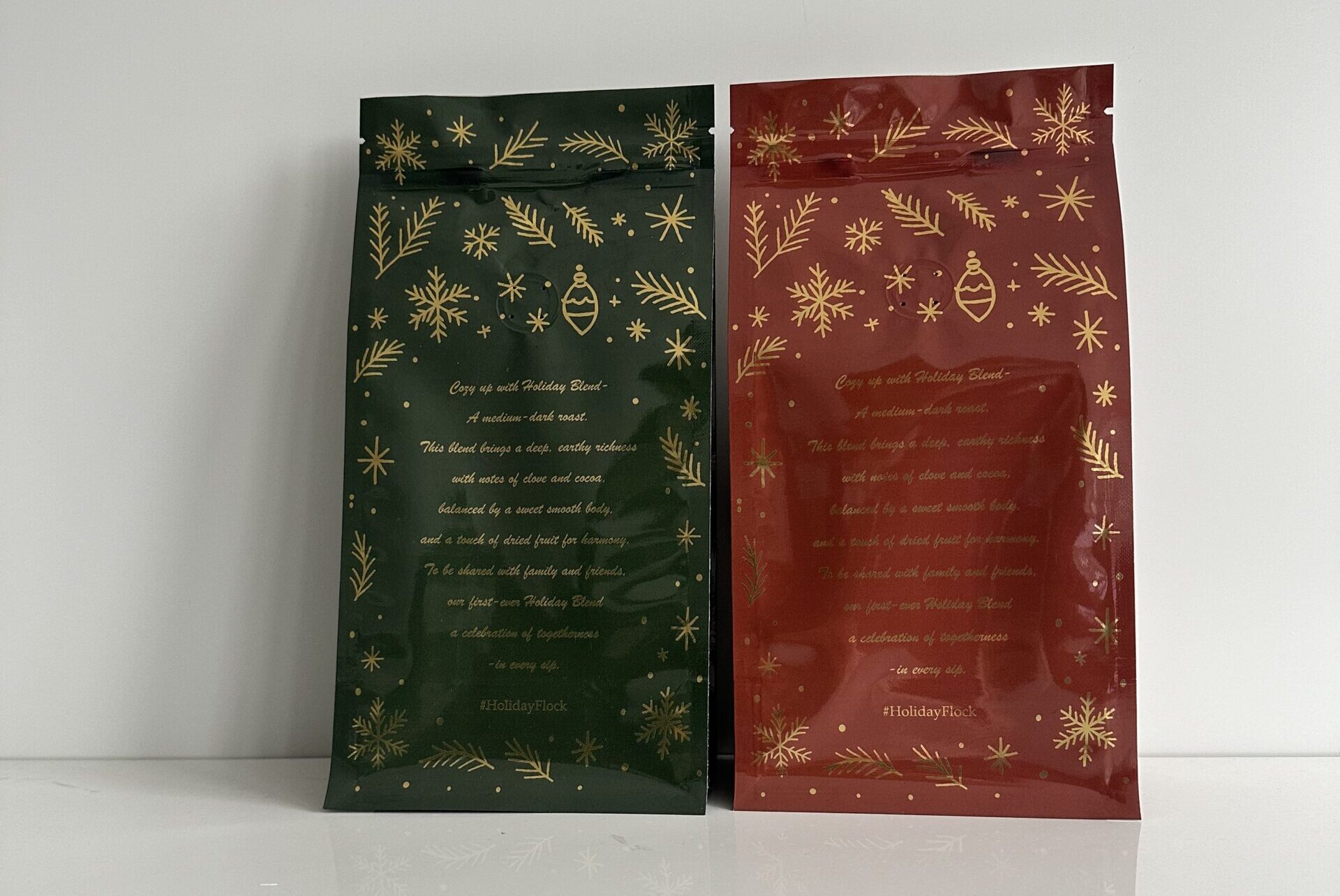

For brands managing 3, 5, or even 20+ SKUs, digital printing is a game-changer. It allows you to print multiple unique designs within the same run—no plate changes, no additional setup costs.

Digital printing benefits for multi-SKU pouch packaging:

- Easy design versioning across SKUs

- Lower MOQs for each version

- Fast turnarounds to respond to changing demand

- Great for product launches, seasonal releases, or subscription boxes

If you’re scaling or testing new SKUs, digital lets you stay nimble without sacrificing quality.

Bundle Multi-SKUs with Custom Kits or Displays

For brands selling multiple pouch SKUs in one package (like variety packs), consider custom kitting, inserts, or countertop displays that hold your pouches together in one unit. This is especially useful for:

- Subscription snack kits

- Sample sets or gift boxes

- Seasonal bundles

- Cross-promotional packs

You can use corrugated boxes, rigid kits, or even printed sleeves and belly bands to package multiple SKUs in a clean, retail-ready format.

Labeling and Inventory Tips

Managing multiple SKUs means more SKUs to track. Here’s how to keep things efficient:

- Use consistent dielines across all pouch sizes if possible

- Make sure each pouch design includes a unique barcode or QR

- Include clear product names and variation callouts (like flavor or strength)

- Store digital print files in a system that makes future updates easy

A well-labeled pouch not only helps in inventory—it also helps customers know exactly what they’re getting.

Final Thoughts

Packaging multiple SKUs with pouches doesn’t have to be overwhelming. With the right combination of standardized formats, flexible printing, and smart kitting or bundling, you can keep your operations lean while still offering the variety your customers love.

Need help building a multi-SKU pouch strategy?

We’ll help you find the right pouch, printing method, and packaging system that fits your brand and simplifies your workflow.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Best Packaging Strategy for Multi-SKU Pouches