Home » Subscription Packaging Buyers’ Checklist for 2026

Subscription Packaging Buyers’ Checklist for 2026

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers should review in 2026 when sourcing or redesigning subscription packaging.

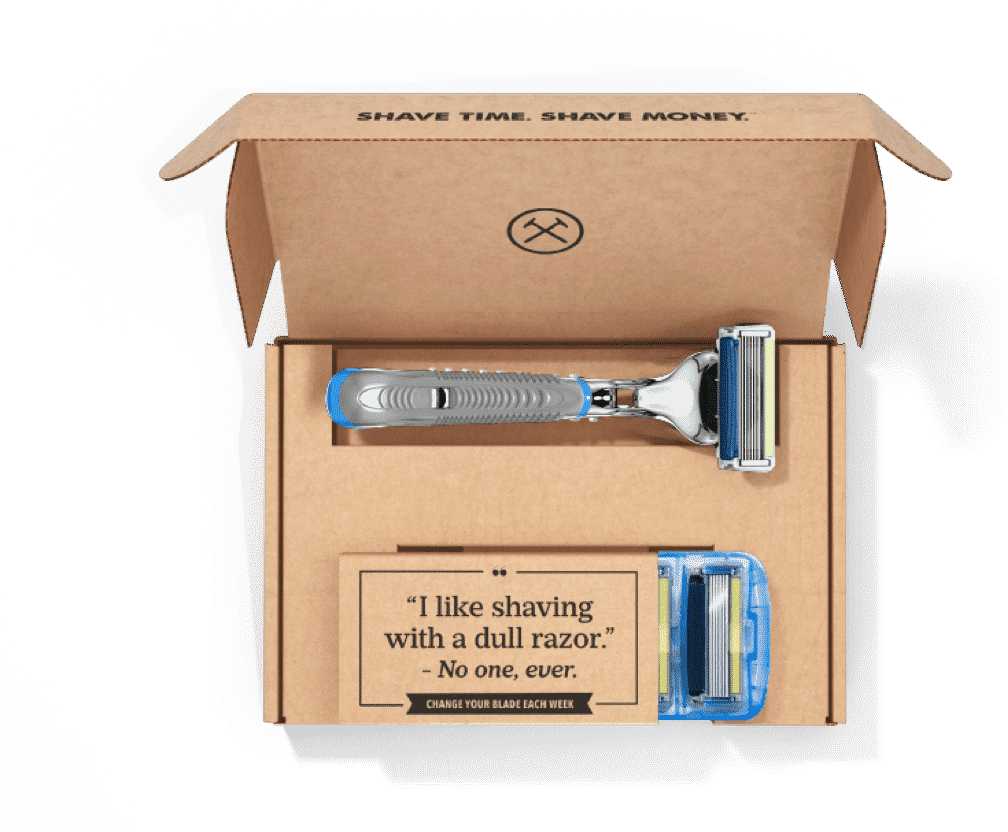

Branding and Unboxing Experience

- Seasonal or rotating graphics to keep unboxing fresh.

- Premium finishes such as foil, embossing, or unique die-cuts.

- Easy-open features like tear strips for convenience.

Right-Sizing and Efficiency

- Reduce DIM charges with packaging tailored to product sizes.

- Use modular designs to cover multiple SKUs with fewer box sizes.

- Ensure packaging works with automation to speed fulfillment.

Protection and Durability

- Inserts that prevent product shifting during transit.

- ISTA-tested designs to withstand vibration and drops.

- Moisture-resistant coatings for temperature-sensitive items.

Sustainability Requirements

- FSC-certified corrugated or recycled substrates.

- Recyclable coatings or compostable options.

- Clear sustainability messaging to support consumer expectations.

Cost Control

- SKU rationalization to limit unnecessary box variations.

- Material selection that balances protection and price.

- Supplier contracts that secure pricing for seasonal peaks.

Packaging Solutions with Brown Packaging

Brown Packaging designs subscription packaging that combines branding, protection, and sustainability. From FSC-certified corrugated to custom inserts, our solutions help buyers create packaging that builds loyalty and controls costs in 2026. Contact us to review your subscription packaging program.

References

Sustainable Packaging Coalition. (2023). Subscription Packaging and Consumer Insights. Retrieved from https://sustainablepackaging.org

Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.org

International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » Subscription Packaging Buyers’ Checklist for 2026

In the competitive retail landscape, the clarity and legibility of pouch packaging play a pivotal role in customer engagement and brand communication. A well-designed package is not just a container for your product; it’s a crucial marketing tool. This blog post delves into the strategies for maximizing clarity and legibility in pouch packaging, ensuring your product stands out on the shelf and communicates effectively with consumers. Understanding the Importance of Clarity and Legibility Clarity and legibility in packaging design are about more than just aesthetics. They directly impact a customer’s ability to quickly identify and understand your product, which can be the deciding factor in the purchasing decision. Clear and legible packaging also ensures compliance with labeling regulations, particularly important in industries like food and pharmaceuticals. Tips for Enhancing Clarity and Legibility Choose the Right Font and Optimize Size: Use simple, easy-to-read fonts for critical information like product names, ingredients, and instructions. Avoid overly stylized fonts that might look attractive but reduce readability. Ensure that the font size is large enough to be read easily from a normal viewing distance. Prioritize key information and make it more prominent. Contrast is Key: Use high-contrast color schemes to enhance readability. Dark text on a light background or vice versa usually works best. Be mindful of colorblindness and avoid color combinations that might pose readability issues. Simplify the Design: Avoid cluttered designs that can overwhelm the eye and make it difficult to locate important information. Use whitespace effectively to create a clean, organized look that draws attention to key details. Use Clear Imagery: Incorporate high-quality images that accurately represent the product. This helps in quick identification and adds to the visual appeal. Ensure that images do not overshadow or interfere with the text. Hierarchical Information Layout: Organize information hierarchically. Place the most important information (like the brand and product name) in the most prominent position. Secondary details should be easily locatable but not dominate the primary information. Incorporate Informative Icons: Use universally recognized icons to convey information quickly, such as gluten-free or vegan symbols. Icons can be a great way to communicate key features without relying on text. Consider the Material and Finish: The material of the pouch can affect visibility. Matte finishes reduce glare, while clear windows can showcase the product directly. Test the legibility against the pouch’s texture and finish under various lighting conditions. Regulatory Compliance: Ensure that all required information, such as nutritional facts, ingredients, and usage instructions, complies with legal requirements in terms of visibility and legibility. Feedback and Testing: Conduct consumer testing to gather feedback on the packaging’s clarity and legibility. Make adjustments based on real-world input to optimize the design. If you are interested in pouch packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging is an essential element of product marketing. It not only protects the product but also plays a significant role in brand identity and consumer perception. One of the key decisions a brand must make when it comes to packaging is whether to choose stand-up pouches or flat pouches. Each option has its own set of advantages and disadvantages, making this decision crucial for the success of the product. In this blog, we will explore the factors brands should consider when deciding between standing up or laying flat for their product packaging. Stand-Up Pouches: The Pros and Cons Stand-up pouches have gained popularity in recent years for their eye-catching design and functionality. They are characterized by their ability to stand upright on store shelves. Here are some advantages and disadvantages of using stand-up pouches: Advantages of Stand-Up Pouches: Visibility and Branding: Stand-up pouches have a strong visual presence on store shelves, making it easier for consumers to spot your product. Their design allows for larger surface areas that can be customized with eye-catching graphics and branding. Space Efficiency: These pouches are space-efficient and can be stacked, maximizing shelf space utilization. This is particularly important in crowded retail environments. Reusability: Stand-up pouches often come with resealable features like zippers or spouts, which can enhance product freshness and convenience for the consumer. Eco-Friendly Options: Brands can choose eco-friendly materials for stand-up pouches, contributing to their sustainability initiatives. Disadvantages of Stand-Up Pouches: Cost: Manufacturing stand-up pouches can be more expensive compared to flat pouches due to the complexity of their design. Stability: While they stand up well on store shelves, stand-up pouches can be less stable during transportation and may require additional packaging to prevent damage. Flat Pouches: The Pros and Cons Flat pouches, also known as pillow pouches, are the traditional choice for packaging various products. They lie flat on shelves and have their own set of advantages and disadvantages: Advantages of Flat Pouches: Cost-Efficiency: Flat pouches are generally more cost-effective to produce compared to stand-up pouches, making them an attractive option for budget-conscious brands. Efficient Storage: They are stackable and take up less space, which can be especially beneficial for storage and transportation. Versatility: Flat pouches can be used for a wide range of products, from snacks to personal care items. Disadvantages of Flat Pouches: Visibility: Flat pouches may not be as eye-catching on store shelves as stand-up pouches. This can potentially lead to lower visibility and lower sales. Limited Branding Space: The smaller surface area of flat pouches limits the space available for branding and product information. Shelf Life: Some products may require airtight or resealable features that are more commonly found in stand-up pouches. Choosing the Right Option Ultimately, the decision between stand-up pouches and flat pouches should be based on the specific needs of your product and your target audience. Here are some key considerations: Product Type: Consider the nature of your product. Stand-up pouches are great for liquid products, snacks, and pet food, while flat pouches work well for items like coffee, chips, and grains. Branding and Visibility: If your brand relies heavily on eye-catching design and branding, stand-up pouches may be the better choice. However, if your product can stand out through other means or if cost is a significant concern, flat pouches might be more suitable. Budget: Evaluate your budget constraints and production costs. While stand-up pouches offer great visual appeal, they can be more expensive to produce. Environmental Considerations: If sustainability is a priority for your brand, explore eco-friendly options for both stand-up and flat pouches. Conclusion: A Future-focused Packaging Solution In conclusion, the food industry’s adoption of flexible packaging is far from arbitrary. It provides a multitude of advantages, including enhanced food safety and shelf life, sustainability, cost-effectiveness, consumer convenience, and innovative branding opportunities. As the food industry continues to evolve and consumer demands shift, flexible packaging will likely become an even more prominent feature of our grocery aisles and kitchen cupboards. It’s not just a trend—it’s a future-focused solution for a more sustainable and efficient food industry. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Subscribe To Our Newsletter Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

Managing packaging for your business is more than just ordering boxes and labels—it’s about sourcing the right materials, coordinating timelines, ensuring quality, and staying aligned with branding and compliance standards. For many buyers, this means juggling relationships with multiple manufacturers for items like corrugated boxes, folding cartons, mailers, tapes, pouches, and displays. But there’s a smarter, more efficient way: working with a single, full-service packaging distributor. Here’s why consolidating your packaging supply chain under one expert partner isn’t just more convenient—it can seriously improve your results. Simplified Project Management Dealing with multiple vendors often means repeating conversations, managing disconnected timelines, and trying to align different production capabilities. A packaging distributor serves as your central point of contact, coordinating every component of your project—from sampling and quoting to delivery and fulfillment. ✔ One contact for all packaging products ✔ Less back-and-forth communication ✔ No gaps between structural design and production ✔ Clear accountability from start to finish Faster Timelines and Better Coordination When you work with multiple manufacturers, each one operates on their own schedule. If your folding cartons are delayed, but your rigid boxes ship early, your entire packaging launch suffers. A distributor ensures that everything is timed to arrive together, preventing slowdowns and misalignment. ✔ Synchronized production timelines ✔ Coordinated delivery and inventory planning ✔ Streamlined launches for multi-component packaging ✔ Improved speed to market Greater Flexibility Across Packaging Types Manufacturers typically specialize in one category—like corrugated, folding cartons, or flexible packaging. But your brand needs more than that. A distributor gives you access to a wide range of packaging formats and materials without having to build separate relationships for each one. ✔ Corrugated boxes, pouches, mailers, displays, and more ✔ One partner for stock and custom packaging ✔ Flexibility to scale or adjust based on product changes ✔ Support across retail, e-commerce, and promotional needs Cost and Volume Optimization Distributors work across hundreds of vendors and manufacturers, which means they can leverage volume buying, negotiate better pricing, and combine orders to keep your costs down. You’re not locked into one manufacturer’s pricing or volume limitations—your distributor finds the best fit. ✔ Access to competitive pricing through volume ✔ Lower MOQs through consolidated buying ✔ Cost savings on bundled services (design, testing, fulfillment) ✔ Custom sourcing based on your budget and goals Customization with Consistency When you’re managing structural design through one vendor, printing with another, and labeling elsewhere, it’s easy to lose brand consistency. A distributor helps ensure that every element of your packaging is aligned—visually and structurally—because it’s all being managed under one roof. ✔ Unified branding across all packaging types ✔ Color-matching and layout alignment ✔ Accurate sizing across inserts, boxes, and displays ✔ One design file applied across multiple formats Support with Compliance, Sustainability, and Retail Requirements Retailers, distributors, and regulators all have packaging requirements—and those can be hard to manage when you’re dealing with multiple suppliers who may not understand your industry. A packaging distributor understands the bigger picture and helps ensure all products meet the same standards. ✔ Knowledge of FDA, USDA, and retailer-specific requirements ✔ Recommendations for recyclable, compostable, and eco-friendly options ✔ Retail-ready display coordination (Target, Costco, Walmart, etc.) ✔ Accurate barcoding, labeling, and structural compliance Scalability and Long-Term Partnership As your business grows, your packaging needs evolve. A manufacturer may only serve one niche, but a distributor can scale with you—offering more product options, faster turnarounds, and additional services like fulfillment, packout, and logistics. ✔ Easy to add new SKUs or packaging formats ✔ Long-term consistency across growing product lines ✔ Ongoing optimization of cost, materials, and design ✔ Built-in support for larger retail rollouts or DTC expansion Final Thoughts Working with multiple packaging manufacturers might seem like a way to shop around—but in reality, it adds unnecessary complexity and cost to your process. A trusted packaging distributor gives you efficiency, control, and scalability, all while helping you get better results with fewer headaches. Looking to simplify your packaging supply chain? We’ll help you manage every detail—from sourcing and design to delivery—so you can focus on growing your business. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts