Home » RSC Box Design Fundamentals: Why It’s the Industry Standard

RSC Box Design Fundamentals: Why It’s the Industry Standard

The Regular Slotted Container (RSC) is the most widely used corrugated box style in the world. Its simplicity, manufacturing efficiency, and versatility make it the default choice across industries ranging from industrial parts to e-commerce fulfillment. Understanding what makes RSC boxes so effective helps buyers decide when standardization is the best approach — and when alternatives may be worth considering.

What Defines an RSC Box

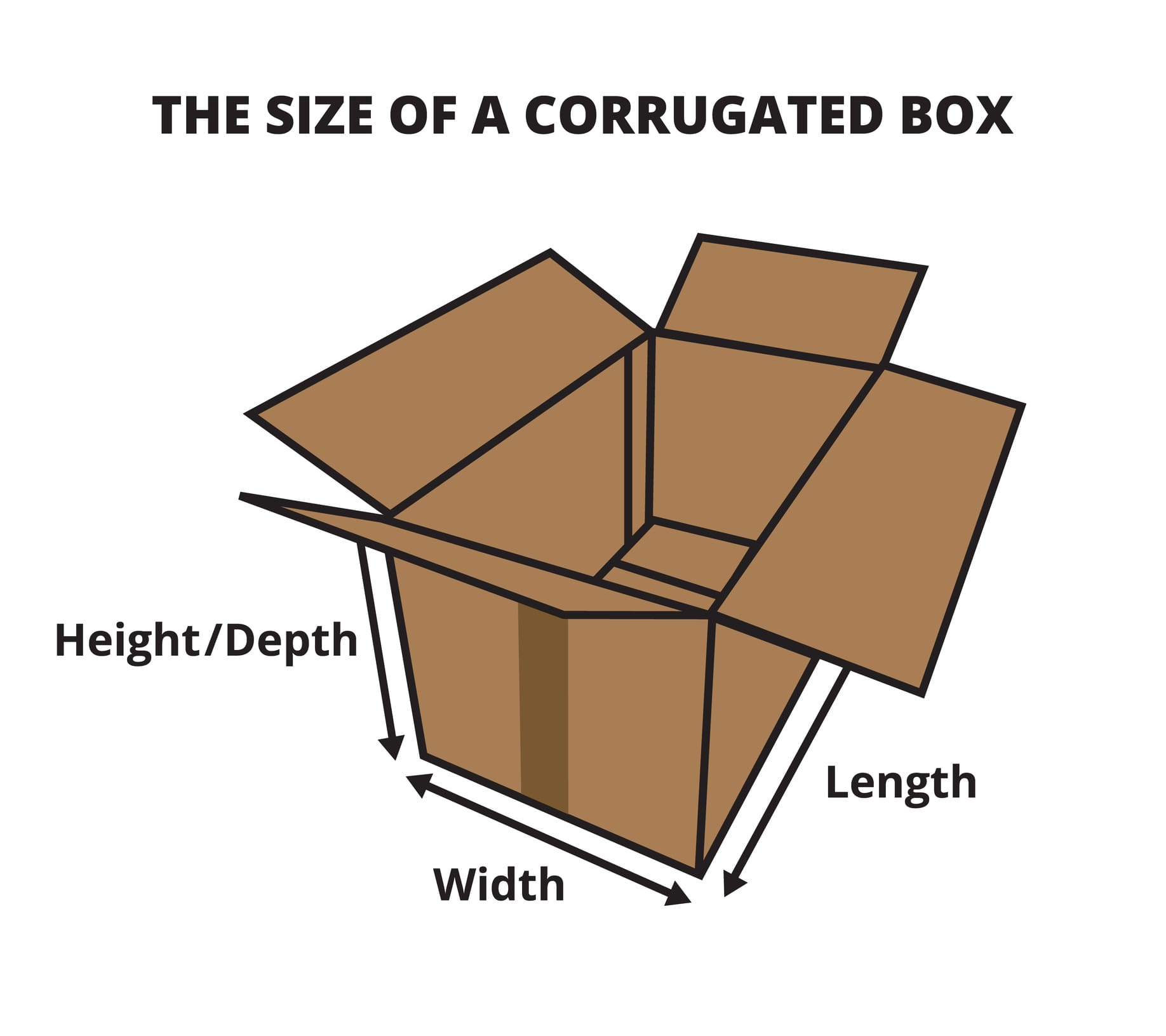

An RSC is manufactured from a single sheet of corrugated board with flaps of equal length that meet at the center when folded. The design minimizes board waste, requires only a single die-cut or slotting process, and can be assembled with tape, glue, or staples. Its dimensions can be adjusted easily to accommodate nearly any product size.

Why RSC Remains the Standard

Manufacturing Efficiency

- RSCs use minimal board compared to other box styles.

- They can be produced on high-speed corrugators and folder-gluers without complex tooling.

- Standardized sizes reduce lead times and lower setup costs.

Structural Strength

- The design maximizes stacking strength with flaps that reinforce the edges of the container.

- Compatible with a wide range of flute profiles and board grades, from single-wall E-flute to triple-wall heavy-duty.

Versatility

- Works for products ranging from lightweight consumer goods to heavy industrial components.

- Compatible with automation in packing, sealing, and palletization systems.

- Easily branded with flexographic or digital print for retail and e-commerce applications.

Cost Effectiveness

- Board utilization is highly efficient, reducing waste.

- Standardized production reduces cost per unit at scale.

- Assembly and sealing are simple, requiring minimal labor and materials.

Limitations of the RSC

While RSC is unmatched for general-purpose shipping, it’s not always the best option:

- Requires tape, glue, or staples, which adds materials and labor.

- Lacks the premium presentation of die-cut mailers for e-commerce.

For unusually heavy or fragile products, other styles (like Full Overlap or RETT) may provide better performance.

Buyer Takeaway

RSC boxes dominate corrugated packaging for one reason: they offer the best balance of strength, efficiency, and cost. If your priorities are bulk shipping, pallet strength, and scalability, RSC is almost always the right choice. But for premium presentation, automation-friendly features, or specialty protection, it’s worth exploring alternative styles.

References

- Fibre Box Association. (2023). Corrugated Box Styles and Design Guide. https://www.fibrebox.org

- Association of Independent Corrugated Converters (AICC). (2024). Corrugated Packaging Fundamentals. https://www.aiccbox.org

- Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping,

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer

Home » RSC Box Design Fundamentals: Why It’s the Industry Standard

Foam-in-corrugated hybrid inserts combine the cushioning properties of foam with the structural rigidity of corrugated board, creating a packaging solution that is both protective and adaptable. This design approach is particularly useful in industries where precision fit and shock absorption are critical, such as electronics, medical devices, and high-value industrial components. Why Combine Foam and Corrugated? Corrugated offers structural stability, vertical stacking strength, and a printable surface for branding or instructions. Foam provides vibration dampening, energy absorption during impact, and surface protection against scratches or abrasions. When integrated, these materials address a broader range of performance requirements than either could alone. Material Selection The choice of foam type—such as polyethylene (PE), polyurethane (PU), or expanded polystyrene (EPS)—should be driven by product fragility, weight, and storage conditions. PE foam, for example, excels in repeated compression recovery, making it suitable for reusable inserts. Corrugated board grades (e.g., single-wall B-flute vs. double-wall BC-flute) must be matched to anticipated stacking loads and compression requirements. Bonding Methods and Compatibility Adhesive selection is critical. Water-based adhesives can warp corrugated under high humidity, while hot-melt options may degrade certain foam chemistries. Mechanical retention methods, such as die-cut lock tabs or slotted cavities, can reduce adhesive usage and improve recyclability. Engineering Fit and Tolerance Control Foam compression should be engineered to 10–30% deflection under typical product weight to balance retention and ease of removal. Corrugated cutouts must account for foam expansion and any dimensional variation due to manufacturing tolerances. Overly tight fits can cause stress concentrations, while loose fits reduce protection efficiency. Shock and Vibration Performance ASTM D1596 testing can determine the foam’s cushioning curve, ensuring the hybrid insert meets drop-test performance requirements. Corrugated structure should be verified under ASTM D642 compression testing to confirm stacking safety in transit and storage. Sustainability Considerations Designing with minimal adhesive, using water-based inks for print, and specifying recyclable PE foams can increase end-of-life recyclability. An emerging approach is designing separable components so the foam and corrugated can be easily disassembled for proper recycling streams. References American Society for Testing and Materials. (2019). ASTM D1596-14: Standard Test Method for Dynamic Shock Cushioning Characteristics of Packaging Material. https://doi.org/10.1520/D1596-14American Society for Testing and Materials. (2015). ASTM D642-15: Standard Test Method for Determining Compressive Resistance of Shipping Containers. https://doi.org/10.1520/D0642-15Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.Kistler, S. F., & Schweizer, P. M. (Eds.). (2013). Liquid Film Coating: Scientific Principles and Their Technological Implications. Springer. https://doi.org/10.1007/978-94-011-4942-0 (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the dynamic world of packaging, two materials often stand at the forefront: traditional corrugated cardboard and its modern counterpart, plastic corrugated. While both have their unique advantages and applications, understanding the nuances between them is crucial for businesses and consumers alike. This blog post delves deep into comparing these two popular packaging materials. Corrugated Cardboard: The Classic Choice History and Composition Corrugated cardboard has been a staple in packaging for over a century. Its structure, featuring a fluted corrugated sheet sandwiched between two flat linerboards, provides a blend of strength and cushioning. Eco-Friendly and Recyclable A significant advantage of corrugated cardboard is its environmental friendliness. Made from renewable resources (mainly recycled paper and pulp), it is biodegradable and widely recycled. Cost-Effectiveness For businesses looking to minimize packaging costs, corrugated cardboard is often the go-to choice. Its materials and production process are relatively inexpensive, making it an economical option for bulk packaging. Limitations However, corrugated cardboard isn’t without its drawbacks. It’s susceptible to moisture and isn’t the most durable option for long-term or heavy-duty packaging. Plastic Corrugated: The Modern Alternative Composition and Durability Plastic corrugated sheets, made from polypropylene or polyethylene, are known for their durability. Unlike cardboard, they are resistant to moisture, chemicals, and impacts, making them suitable for more rigorous applications. Reusability and Longevity One of the most significant advantages of plastic corrugated is its reusability. These materials can withstand repeated use without significant degradation, offering long-term cost savings despite a higher initial cost. Versatility Plastic corrugated is available in various colors and can be easily customized, offering aesthetic and branding advantages. Its flexibility in design makes it ideal for specialized packaging needs. Environmental Considerations While plastic corrugated is recyclable, its environmental impact is a point of contention. The recycling process is more complex than that of cardboard, and if not properly recycled, it contributes to plastic pollution. Choosing the Right Material for Your Packaging Needs Assessing Product Requirements The choice between corrugated and plastic corrugated depends largely on the product being packaged. For lightweight, short-term, or cost-sensitive applications, corrugated cardboard is often sufficient. However, for heavier, long-term, or moisture-sensitive products, plastic corrugated may be the better option. Cost vs. Sustainability Budget constraints and environmental considerations play a significant role. Businesses committed to sustainability might prefer corrugated cardboard, while those requiring durability and long-term use might lean towards plastic corrugated. If you are interested in corrugated or plastic corrugated packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated ESD Design Display Foam Folding Carton Packaging Plastic Packaging Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Plastic Corrugated Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of logistics and e-commerce, shipping is a critical aspect of business operations. Among the various packaging options, the Regular Slotted Container (RSC) box stands out as a versatile choice for shipping a wide range of products. To ensure your shipping endeavors with RSC boxes are both effective and efficient, it’s crucial to follow best practices and strategies. In this article, we’ll explore the key approaches to successfully ship RSC boxes. Choose the Right RSC Box Size Selecting the appropriate box size is essential when using RSC boxes for shipping. Oversized boxes waste space and may lead to higher shipping costs, while undersized boxes risk damaging your products. Therefore, it’s vital to measure your items carefully and opt for an RSC box that provides a snug fit with minimal extra space. Quality Matters Invest in high-quality RSC boxes. Boxes made from sturdy corrugated cardboard with durable seams and proper adhesive are crucial for protecting your products during transit. Quality boxes ensure that your goods reach their destination in optimal condition, without suffering damage due to external forces such as crushing or impacts. Proper Packing Material In addition to selecting the right RSC box, choosing the appropriate packing materials is equally important. Use cushioning materials like bubble wrap, packing peanuts, corrugated or foam inserts to safeguard your products from shocks and vibrations during shipping. Ensure there’s an adequate buffer between the product and the inner walls of the box. Seal Boxes Securely Properly sealing your RSC boxes is vital to prevent any unintended openings during shipping. Use high-quality packing tape to securely seal both the top and bottom flaps of the box. Ensure that the seams are tightly sealed, with no gaps or openings that could compromise the integrity of the box. Labeling and Documentation Clearly label each RSC box with essential information, including the recipient’s address, your return address, and any special handling instructions. Employ high-quality labels that won’t smudge or peel during transit. Additionally, don’t forget to include any required shipping documentation, such as packing slips, invoices, or customs forms, especially when shipping internationally. Weight Distribution Evenly distribute the weight of your products within the RSC box. Avoid placing heavy items on top of delicate ones. Utilize dividers or partitions if necessary to prevent items from shifting during transit. This practice helps maintain the structural integrity of the box and ensures that the products remain secure. Consider Environmental Impact Incorporate eco-friendly practices into your shipping process. Opt for recyclable and biodegradable packing materials whenever possible. Additionally, choose RSC boxes made from sustainable or recycled materials to reduce your environmental footprint. Shipping Carrier Selection Select a reputable shipping carrier that aligns with your business needs. Factors to consider include shipping speed, cost, reliability, and coverage. Negotiating shipping rates and exploring bulk shipping options can help reduce shipping costs. Track Shipments Utilize tracking services provided by shipping carriers. This enables you to monitor the progress of your shipments, provide customers with accurate delivery estimates, and promptly address any issues that may arise during transit. If you are interested in RSC Boxes, custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom RSC Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts