Home » How Finishes Protect Printed Packaging

How Finishes Protect Printed Packaging

Printed packaging plays a crucial role in brand perception, shelf appeal, and the overall customer experience—but the work doesn’t stop once the ink hits the surface. Without the right finish, that print is vulnerable to scuffs, fading, moisture, and friction during production, handling, or shipping.

Whether you’re working with corrugated boxes, folding cartons, or rigid boxes, finishes do more than elevate appearance—they’re your first line of defense in protecting print. Here’s how the right finish keeps your packaging looking sharp from press to doorstep.

Why Finishes Matter

Your packaging travels through a lot—automated fulfillment, stacking, freight, climate changes, and customer handling. Finishes act as a protective shield, sealing the printed surface and improving the durability, longevity, and professional appearance of the box.

Without a finish, print can:

- Rub off or smudge

- Fade under UV exposure

- Scuff or tear during shipping

- Absorb moisture or oils from hands

A finish helps maintain the integrity of the design and branding under real-world conditions.

Common Finishes That Add Protection

Aqueous Coating

A water-based coating that dries quickly and provides light protection against scuffing, fingerprints, and dirt.

✅ Ideal for folding cartons and corrugated boxes

✅ Cost-effective, eco-friendly, and adds a subtle shine or matte finish

✅ Can be applied inline during printing for fast turnaround

UV Coating

A high-gloss or matte coating cured with ultraviolet light, offering stronger protection than aqueous.

✅ Great for high-touch surfaces

✅ Resists abrasion and moisture

✅ Frequently used on folding cartons and rigid boxes

Soft-Touch Coating

A smooth, velvet-like matte finish that enhances tactile feel while offering surface protection.

✅ Popular in rigid boxes and premium folding cartons

✅ Pairs well with foil stamping and embossing

✅ Resists fingerprints and minor scuffs

Lamination (Gloss or Matte)

A plastic film applied to the printed surface, offering the highest level of protection against tearing, moisture, and surface wear.

✅ Common in litho-labeled corrugated and rigid boxes

✅ Adds structure and premium feel

✅ Excellent for high-end retail packaging or long shelf-life applications

Spot UV

A selective UV coating applied only to certain parts of the design (like logos or images).

✅ Protects key branding elements

✅ Adds contrast and visual depth

✅ Best used in combination with other finishes

How Finishes Vary by Box Type

Corrugated Boxes

Corrugated boxes are often exposed to rough handling and shipping abuse. For printed corrugated:

- Aqueous coating protects basic graphics in litho-label or digital runs

- Laminated litho labels offer the best protection and visual appeal

- Inside print (protected by the box itself) is an option for minimal damage risk

Folding Cartons

Folding cartons are more likely to be handled in retail and must look good under bright lights.

- Gloss or matte coatings resist scuffing on shelves

- Soft-touch adds luxury while improving grip

- Spot UV can highlight key details while protecting them

Rigid Boxes

Often used for luxury goods, rigid boxes require both durability and a premium finish.

- Lamination protects litho labels from edge cracking or peeling

- Soft-touch and foil can be layered for both tactile appeal and surface protection

- Embossing with a finish ensures your raised designs stay clean and sharp

Final Thoughts

A finish isn’t just a design choice—it’s a functional upgrade that preserves the quality, readability, and impact of your printed packaging. Whether you’re shipping across the country or selling on a shelf, the right finish protects your investment and keeps your brand looking its best.

Need help selecting the right finish for your boxes?

We’ll guide you through coatings, lamination, and protective treatments tailored to your packaging type and brand goals.

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the

Home » How Finishes Protect Printed Packaging

In today’s competitive market, packaging affordability doesn’t start with cheaper materials — it starts with smarter design. Every score, fold, and insert decision affects not only how a box looks and feels, but how efficiently it’s made, shipped, and used. Structural engineering is the silent driver of cost efficiency — optimizing strength, space, and performance before the first sheet is ever printed. Why Structure Matters More Than You Think The most impactful cost savings in packaging rarely come from supplier discounts; they come from structural efficiency.A box that uses 10% less board but maintains the same compression strength directly reduces both material and freight cost. A redesigned insert that eliminates the need for secondary packaging saves time and labor at the line. Every cut line and fold path tells a story of cost, sustainability, and brand care — and when those align, affordability becomes part of your brand’s DNA. Designing for Efficiency, Not Excess In a market saturated with overbuilt packaging, engineering restraint is a competitive advantage. Structural teams now rely on 3D CAD modeling and virtual prototyping to simulate performance before production — identifying unnecessary material use and structural redundancies. Through precision die-line planning, engineers can improve sheet yield, reduce assembly time, and minimize void space — the dead air that drives up freight bills.It’s not about doing less; it’s about doing smarter. Balancing Protection and Presentation The temptation to “overprotect” products is common — especially in fragile or high-value goods. But protection doesn’t have to mean bulk. Strategic reinforcements, engineered fluting, and interlocking designs can maintain crush resistance and shock absorption while reducing total board weight. For e-commerce and shelf packaging alike, brands can achieve premium presentation with structural simplicity — a key to making packaging both sustainable and affordable. Prototyping to Prevent Waste Prototyping isn’t just for aesthetics — it’s a safeguard against costly production errors.With short-run sample testing and performance mockups, brands can evaluate fit, function, and protection early in development. Adjusting dimensions by fractions of an inch can save thousands in material waste and prevent rejected runs down the line. Smart packaging buyers now view prototyping not as an expense, but as a cost-control strategy that pays dividends in scale. How Structural Design Supports Brand and Budget Affordable design doesn’t mean compromising brand identity — it means integrating brand goals into structure. A well-engineered box reinforces trust, ensures product consistency, and communicates value through precision and fit. When structure, design, and production align, packaging stops being a cost and starts becoming a business asset. That’s where the real savings live — and where long-term brand equity begins. The Brown Packaging Difference At Brown Packaging, every packaging solution starts with structural intent — not guesswork.Our engineering and design teams collaborate to create packaging that performs across shipping, retail, and automation lines, balancing protection, brand visibility, and cost efficiency. We don’t cut corners; we cut waste.That’s how our clients achieve packaging that’s not just affordable — it’s engineered to perform. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. PMMI. (2024). Optimizing Structural Design for Packaging Efficiency. Packaging World. (2025). Engineering the Future of Cost-Effective Packaging. Smithers. (2025). Packaging Innovation and Material Efficiency Trends. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Medical device packaging plays a crucial role in protecting products, ensuring sterility, and enhancing user confidence. Beyond just functionality, packaging influences customer perception, which can directly impact a company’s reputation, product adoption, and market success. When customers—including hospitals, healthcare providers, and patients—receive a medical device, the first interaction is with the packaging, making it a critical factor in trust and credibility. How Packaging Affects Customer Perception Trust and Brand Credibility In the medical field, trust is paramount. Packaging that looks clean, professional, and tamper-proof reassures customers that the device inside is safe and high quality. Poorly designed or damaged packaging, on the other hand, can raise concerns about contamination or product reliability, negatively affecting customer confidence. Compliance and Safety Assurance Customers expect medical devices to meet strict regulatory standards for safety and sterility. Packaging that clearly displays compliance certifications (FDA, ISO, CE), expiration dates, and handling instructions reassures end-users that the product is reliable and meets industry standards. Conversely, unclear or missing information can create hesitation or even rejection of the product. Ease of Use and Accessibility Medical professionals and patients often interact with packaging in high-pressure environments, where ease of access is essential. Packaging should be intuitive, easy to open, and designed for quick, safe product retrieval. If packaging is difficult to open or use, it can lead to frustration, delays in treatment, or even damage to the device before use. Tamper Evidence and Product Integrity Medical device packaging must incorporate tamper-evident features to ensure product integrity. Seals, RFID tracking, and authentication labels help customers feel secure that the product hasn’t been compromised. If packaging appears tampered with or unsecure, it can result in returns, complaints, or loss of trust in the brand. Optimizing Medical Device Packaging for Positive Customer Perception To ensure packaging creates a strong, positive impression, companies should consider: High-quality materials that ensure product protection and sterility. Clear and concise labeling to provide essential information without clutter. User-friendly design for accessibility in both clinical and home settings. Tamper-proof features to prevent unauthorized access and enhance security. Final Thoughts: Why Packaging Perception Matters Customer perception of medical device packaging is as important as the device itself. Trust, safety, ease of use, and branding all play a role in how a product is received. Investing in high-quality, well-designed packaging not only ensures compliance but also enhances user confidence and strengthens brand reputation. Looking to improve your medical device packaging solutions? Contact Brown Packaging today for expert insights and customized packaging solutions that align with industry standards and customer expectations. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Medical Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

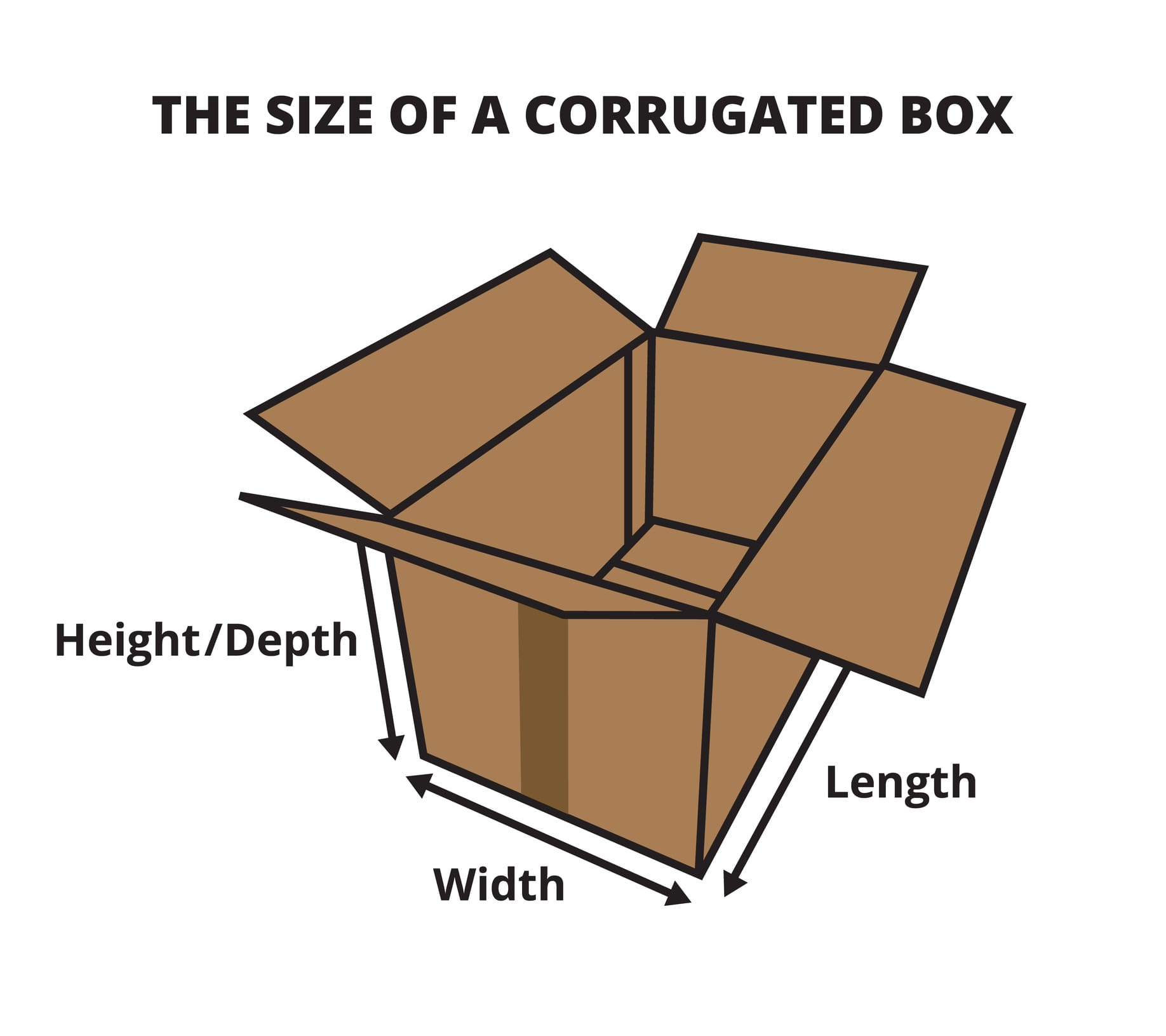

Structurally designing your corrugated box involves understanding the specific requirements of your product and applying principles of material science and engineering to ensure optimal protection, efficiency, and cost-effectiveness. This process requires careful consideration of the box’s dimensions, material grade, flute type, and the intended use to create a packaging solution that meets both logistical and aesthetic needs. Understanding the Basics of Corrugated Boxes Before diving into the design process, it’s important to grasp the fundamental components of a corrugated box: Fluting: The wavy layer of corrugated paper that provides cushioning and strength. The size, type and the material of the flute affect the box’s compression strength, stacking strength, and crush resistance. Linerboards: Flat sheets of paper that sandwich the fluting, contributing to the box’s durability and structural integrity. Box Types: Common configurations include the Regular Slotted Container (RSC), Full Overlap (FOL), and Die-Cut designs, each offering different benefits in terms of protection and assembly efficiency. Step 1: Assess Product Requirements Start by evaluating the weight, dimensions, and fragility of the product. Consider any additional space needed for internal packaging materials like bubble wrap or foam inserts, which provide extra protection for delicate items. This assessment will guide the choice of box size and strength needed to ensure safe transport and storage. Step 2: Select Material and Flute Type Choose the appropriate material grade and flute type based on the product’s weight and the level of protection required. For lightweight items, a single-wall box with smaller flutes like B or C may suffice. Heavier or more fragile items may require double-wall or triple-wall boxes with larger flutes like A or BC for increased cushioning and strength. The Edge Crush Test (ECT) rating of the cardboard is a critical factor here, indicating the box’s ability to withstand external pressures. Step 3: Design for Efficiency and Sustainability Efficiency in packaging not only reduces material costs but also minimizes waste, contributing to sustainability. Design your box to fit your product snugly while allowing for minimal extra packaging material. Consider using recyclable materials and designing for ease of recycling after use, such as avoiding mixed materials that are difficult to separate. Step 4: Prototype and Test Once the initial design is established, create a prototype of your box. This allows for hands-on testing to ensure the box meets your requirements in terms of size, strength, and functionality. Conduct tests that mimic real-world handling, shipping, and stacking scenarios to identify any structural weaknesses or design flaws. Step 5: Customization and Branding Customization isn’t just about aesthetics; it can also enhance the box’s structural integrity. For example, die-cut inserts not only secure products within the box but also add rigidity to the structure. Use the exterior for branding, but ensure that any printing or customization does not compromise the box’s strength. Step 6: Iterate Based on Feedback Use feedback from the testing phase to refine your design. This may involve adjusting dimensions, changing the flute type, or reevaluating the material grade. Iteration is a crucial step in optimizing the design for both protection and cost. Conclusion Structurally designing a corrugated box is a detailed process that blends science, engineering, and aesthetics. It requires a deep understanding of the product needs, material properties, and the logistical demands of shipping and handling. By following these steps and focusing on both function and form, you can develop a corrugated box that not only protects your product but also enhances your brand’s presentation and sustainability efforts. If you are interested in custom structurally designed corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts