Home » Logistics and Installation: Streamlining POP Display Deployment

Logistics and Installation: Streamlining POP Display Deployment

The final steps in deploying a permanent and semi-permanent Point of Purchase (POP) display involve the logistics of distribution and the specifics of installation. Effective management of these stages is crucial to ensure that your displays are set up correctly, on time, and with optimal impact. This blog will guide you through the logistics and installation processes, providing insights on how to streamline these operations for maximum efficiency and effectiveness.

Planning and Coordinating Logistics

Understanding Distribution Requirements

Begin by assessing the distribution requirements for your POP displays. Consider the number of locations, geographical spread, and the timeline for deployment. Effective logistics planning ensures that all displays reach their intended locations without delays or damage.

Choosing a Distribution Partner

Selecting the right logistics partner is vital. Look for providers with experience in handling retail displays, as they can offer specialized services such as on-time delivery to multiple locations, careful handling of materials, and even storage solutions if needed.

Packaging for Protection

Ensure that the POP displays are packaged securely to prevent damage during transit. This might involve custom crating or protective padding, especially for more delicate components. The goal is to have the displays arrive in pristine condition, ready for installation.

Efficient and Effective Installation

Preparing Installation Guidelines

Provide clear, detailed installation guidelines to ensure consistent setup across all locations. This should include instructions on assembly, placement, and any necessary tools or materials. Proper guidelines help minimize errors and reduce the time needed for installation.

Training Teams or Hiring Professionals

Decide whether to train your staff for installation or to hire professional installers. Training in-house teams can be cost-effective and allow for more control over the process. However, professional installers can offer the advantage of experienced, quick, and reliable setup, which might be crucial for complex displays or large-scale rollouts.

Coordinating with Retail Locations

Work closely with the management of the retail locations where the displays will be installed. Coordination is essential for ensuring that the installation process does not disrupt business operations and that the display is placed in the most effective spot within the store.

On-site Adjustments

Be prepared for on-site adjustments. Even with thorough planning, the need for minor tweaks during installation is common. Quick decision-making and adaptability can help overcome any unforeseen challenges that arise during the setup.

Monitoring and Troubleshooting

Initial Feedback Loop

Once the displays are installed, establish an initial feedback loop with the store managers and installation teams. Gather insights on the installation process and the initial response of customers to the displays. This feedback can be invaluable for making any immediate adjustments and for improving future deployments.

Ongoing Maintenance

Plan for the maintenance of the displays to ensure they remain attractive and functional throughout their intended lifespan. This might involve regular check-ups, cleaning, and repairs. Maintaining the displays well can significantly enhance their effectiveness and protect your investment.

Conclusion

Logistics and installation are critical phases in the deployment of POP displays. Efficiently managing these aspects ensures that your displays are set up to attract and engage customers effectively. By focusing on careful planning, clear communication, and flexibility, you can streamline these processes to achieve a successful display rollout that meets both your operational goals and marketing objectives.

If you are interested in POP displays, then partner with Brown Packaging today to get started.

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Sustainability is now a top priority for packaging buyers. Retailers, regulators, and consumers are all demanding packaging solutions that reduce environmental impact without sacrificing performance. In 2026, buyers must balance eco-friendly materials, cost, and compliance to build programs that are both effective and future-ready. What Buyers Need to Know About Sustainable Packaging Regulatory pressure: Governments are enforcing stricter rules on recyclability and plastic use. Retail mandates: FSC certification and recyclable packaging are becoming standard requirements. Consumer expectations: Customers increasingly choose brands with visible sustainability commitments. Sustainable Material Options Recycled corrugated: High recycled content while maintaining compression strength. Compostable films: Suitable for select food and retail applications. Molded pulp inserts: Replace foam or plastic for protective packaging. Water-based coatings: Enhance moisture resistance without harmful chemicals. Balancing Cost and Performance Right-size packaging: Reduces material waste and shipping costs. Hybrid solutions: Combine eco-materials with corrugated for balance. Life cycle analysis: Evaluate true environmental impact, not just marketing claims. How to Evaluate Sustainable Suppliers Verify FSC, SPC, or ISO certifications. Request testing data for durability and recyclability. Audit supply chains for consistency and transparency. Ensure claims meet local and international compliance standards. Packaging Solutions with Brown Packaging Brown Packaging helps buyers implement sustainable packaging programs that balance cost, performance, and compliance. From recycled corrugated to eco-friendly coatings and inserts, we deliver solutions that meet 2026 sustainability goals. Contact us to explore sustainable packaging options. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Sustainability Trends and Buyer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced performance and protection. Understanding the trade-offs helps companies balance cost, functionality, and sustainability goals in 2026. What Is Single-Material Packaging? Single-material packaging uses one substrate—such as corrugated board, folding carton, or plastic—for the entire structure. Advantages: Easier to recycle and dispose. Lower material costs in many cases. Streamlined sourcing and inventory. Supports sustainability messaging. Disadvantages: Limited barrier protection. Less customization for fragile or complex products. May require added thickness for strength, increasing weight. What Is Multi-Material Packaging? Multi-material packaging combines two or more substrates—such as corrugated with foam, or paperboard laminated with film—to achieve specific performance outcomes. Advantages: Greater protection against moisture, oxygen, and impact. Allows for premium finishes and enhanced graphics. Ideal for fragile or high-value products. Customizable for unique supply chain conditions. Disadvantages: More difficult to recycle due to material separation. Higher cost and longer lead times. Complex sourcing and inventory management. When to Use Each Approach Single-material packaging: Best for products with low fragility, strong sustainability requirements, or cost-driven programs. Multi-material packaging: Best for high-value, fragile, or regulated products requiring advanced protection. Balancing Performance and Sustainability Buyers must weigh performance needs against eco goals: Use recyclable coatings to extend single-material performance. Choose hybrid designs that separate easily for recycling. Apply multi-material solutions only where risk of damage outweighs cost. Packaging Solutions with Brown Packaging Brown Packaging helps buyers evaluate when to use single- vs. multi-material packaging. Our team balances sustainability, performance, and cost to deliver solutions tailored to your supply chain. Contact us to explore the right approach for your products. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Sustainable Packaging Coalition. (2022). Design for Recyclability and Multi-Material Packaging Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Logistics and Installation: Streamlining POP Display Deployment

POP display design must serve two masters — maximizing visual impact in-store while minimizing logistics costs. Engineering the right balance between display footprint, assembly complexity, and shipping volume is critical to meeting retailer requirements and protecting margins. Knock-Down vs. Fully Assembled Designs Knock-Down (KDF) Displays: Pros: Reduced shipping volume, lower freight costs, easier warehousing. Cons: Requires assembly labor at store level, potential for setup errors. Fully Assembled Displays: Pros: Guaranteed presentation quality, faster deployment. Cons: Higher dimensional freight costs, risk of damage in transit. Freight Optimization Factors Cube Utilization: Designing displays to fit standard pallet footprints (40×48 inches) and trailer heights improves load efficiency. Dimensional Weight (DIM): Carriers charge based on the higher of actual or volumetric weight; bulky but light displays can be costly to ship. Palletization Patterns: Consistent stacking reduces shifting and improves load stability. Structural Engineering Considerations Flat-Pack Engineering: Modular components with interlocking tabs reduce the need for fasteners. Material Selection: Lighter substrates reduce freight weight but must still meet load-bearing requirements. Protective Packaging: Corner protectors and slip sheets prevent in-transit abrasion. Shelf Presence Strategies Without Bulk Tiered Merchandising: Maximizes SKU visibility without increasing footprint. Bold Header Cards: Achieves eye-level engagement without adding weight. Interchangeable Graphic Panels: Allows seasonal refresh without replacing the structural base. Testing and Compliance ISTA 3E: Simulates unitized load handling for large-format displays. Retailer Compliance Manuals: Many major retailers specify maximum dimensions, palletization methods, and setup time allowances. References International Safe Transit Association. (2018). ISTA 3E: Packaged-products for unitized loads. ISTA. https://ista.orgWalmart. (2024). Retail link supplier compliance guidelines. Walmart Inc. https://www.walmart.com/suppliersTarget. (2024). Target merchandising display guidelines. Target Brands, Inc. https://corporate.target.com (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts

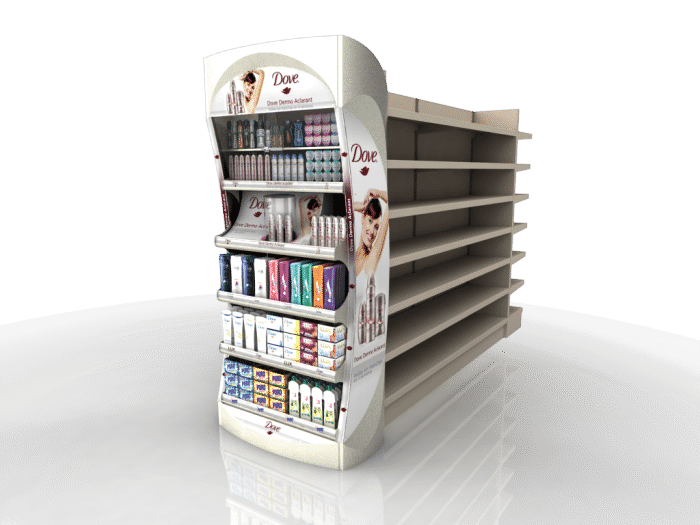

In the bustling world of retail, where competition is fierce and every inch of shelf space matters, staying ahead requires innovation. You’ve cultivated an exceptional business, a skilled team, and a compelling product lineup. However, you’ve noticed that certain competitors seem to be outselling you. Naturally, you’re intrigued and want to explore avenues that can give you a competitive edge. This is where Point of Purchase (POP) displays come into play. Demystifying Point of Purchase Displays Picture yourself navigating the aisles of your local supermarket. Amidst the array of neatly organized products on the shelves, your attention is irresistibly drawn to a strategically positioned display that showcases a selection of items. This strategic arrangement is what’s known as a Point of Purchase (POP) display – a dynamic solution that has the potential to transform your products from ordinary to attention-grabbing. Unveiling the Influence of POP Displays The essence of a POP display is simple yet remarkably effective. It’s a custom-made display set apart from its usual shelf location, demanding attention in the store. Unlike typical shelf arrangements, POP displays are often situated at the heart of aisles or at aisle ends, ensuring maximum visibility. This placement empowers your products with heightened prominence and branding opportunities, allowing them to shine amidst the retail landscape. The Artistry of Presentation A standard POP display takes physical form with one to four sides, frequently crafted from corrugated cardboard – as depicted in the accompanying image. Imagine the ingenuity employed for canned beverages, where soda or alcohol cases are stacked in creative patterns to create an enticing shape. Each structure houses a curated selection of products, adorned with a strategic interplay of design elements such as color palettes, typography, pricing details, logos, visuals, and product imagery. This symphony of visuals ensures your products seize attention in the bustling retail environment. Captivating Attention, Driving Sales The allure of POP displays lies in their ability to capture attention and drive sales. Recall your recent visit to a retail giant like Walmart. Those thoughtfully positioned displays that commanded your gaze were POP displays. It’s likely you’ve even succumbed to their appeal and made a purchase based on their captivating presentation. By breaking away from conventional shelf placements, POP displays adeptly capture shopper interest, translating to higher conversions and amplified sales for the featured products. Versatility in Application The realm of POP displays isn’t confined; it spans diverse retail settings. In expansive retail spaces like Walmart, you’ll encounter four-sided POP displays gracing main aisles – known as “action alleys.” These displays, strategically positioned every 10-20 feet, proudly exhibit an array of products encompassing, video games, books, beverages, and packaged foods. Smaller, one or two-sided POP displays mark the end of each aisle, seamlessly connecting to the larger shopping thoroughfares. From Retail Titans to Local Treasures While major retailers prominently showcase these displays, smaller establishments also reap rewards. Gas stations, country stores, auto parts shops, and neighborhood boutiques effectively utilize one or two-sided POP displays to allure customers and heighten product visibility. These displays function as compelling marketing tools, effectively conveying your product’s value proposition and encouraging impulse purchases. Elevate Your Retail Strategy with POP Displays In the relentless world of retail competition, innovation is your formidable ally. Enhance your sales prowess by harnessing the potential of POP displays. Their strategic placement, captivating designs, and enhanced visibility can convert casual browsers into enthusiastic purchasers. Whether you’re an industry titan akin to Walmart or a local gem nestled in a community, integrating POP displays can serve as your enigmatic ingredient for retail triumph. If you are interested in point of purchase displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

In the competitive retail landscape, capturing consumers’ attention is more crucial than ever. One strategic approach to achieve this is through effective point of purchase (POP) displays. These displays, positioned strategically at checkout counters or end-of-aisle locations, can significantly impact your bottom line and maximize your return on investment (ROI). This blog will provide valuable tips and tricks on how to leverage POP displays to optimize sales and enhance customer experience. Understanding the Power of POP Displays POP displays serve as a powerful marketing tool, grabbing customers’ attention and stimulating impulsive buying behaviors. Well-designed and positioned displays can highlight products, create a sense of urgency, and encourage add-on purchases, ultimately driving higher sales. Tips and Tricks to Maximize ROI with POP Displays Strategic Placement Placement is key when it comes to POP displays. They should be located in high-traffic areas, such as near checkout lines or at the end of aisles. These locations often have the highest visibility and can effectively prompt last-minute purchase decisions. Eye-Catching Design Ensure your displays stand out by implementing eye-catching designs. This could involve using vibrant colors, engaging graphics, or innovative structures. Additionally, the use of clear and concise messaging can convey the product’s benefits and create a sense of urgency. Rotate Displays Regularly Regularly changing your displays keeps the retail environment fresh and engaging. It encourages repeat customers to explore new products and prevents display blindness, where consumers overlook the display due to familiarity. Optimize for Product Interaction Allowing customers to touch and interact with the product can lead to higher sales. Design your POP displays in a way that products are easily accessible and can be handled by customers. Use Cross-Merchandising Techniques Consider pairing related items together in your POP display. This cross-merchandising strategy can encourage multiple purchases and increase the overall sales value per customer. Measure Performance Implement tracking measures to analyze the effectiveness of your POP displays. This can be as simple as tracking sales of displayed products or as complex as using technology like heat maps or customer journey analysis. The insights can inform your future display strategies and help optimize ROI. Leveraging Technology for Enhanced POP Displays In the digital age, technology can significantly enhance the effectiveness of displays. Interactive displays, augmented reality (AR), or digital signage can provide a unique and engaging customer experience, further driving impulse purchases and boosting sales. Wrapping Up: A Worthwhile Investment In conclusion, while creating effective POP displays requires an initial investment, it can lead to significant returns in terms of increased sales, customer engagement, and brand recognition. By employing these tips and tricks, retailers can truly harness the power of their displays to maximize their ROI. If you are interested in POP Display and need help maximize your displays potential, then contact Brown Packaging today. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts