Home » Exploring Packaging Tradeoffs: Shelf-life vs. Costs

Exploring Packaging Tradeoffs: Shelf-life vs. Costs

In the world of packaging, there’s a constant tug-of-war between two critical factors: extending the shelf life of products and controlling costs. This delicate balancing act requires businesses to make strategic decisions that align with their objectives and market dynamics. In this exploration, we’ll delve into the intricate tradeoff between shelf life and costs, examining the interconnectedness of these factors and how businesses can navigate this complex landscape.

Packaging Priorities

When considering packaging options, companies must weigh the significance of extending shelf life against the imperative of controlling costs. These two aspects are closely intertwined, and understanding their interplay is essential:

Extending Shelf Life

Extending the shelf life of products carries multifaceted advantages:

- Enhanced Product Quality: A prolonged shelf life ensures that products maintain their quality, flavor, and efficacy, translating into higher customer satisfaction.

- Waste Reduction: By reducing spoilage and the deterioration of goods, companies can curtail waste, aligning with both environmental and economic sustainability.

- Broader Market Reach: Products with extended shelf lives can access wider markets, including regions with extended distribution chains or markets where products may sit on shelves for prolonged periods.

- Fortified Brand Reputation: Offering products with extended shelf life can bolster a brand’s reputation for delivering reliability and quality.

Cost Control

Effective cost control is crucial for profitability and competitiveness:

- Competitive Pricing: Cost-efficient operations enable businesses to offer competitive prices, attracting price-conscious consumers.

- Profit Margin Enhancement: Improved cost control directly impacts profit margins, contributing to the financial health of the business.

- Investment in Innovation: Redirecting cost savings towards research and development allows companies to innovate and stay ahead in the market.

- Market Expansion: Lower production costs may facilitate market expansion and investments in marketing and promotional activities.

The Interplay Between Shelf Life and Costs

The connection between extending shelf life and controlling costs becomes evident when considering the following scenarios:

- Enhanced Packaging Materials: Investing in high-quality packaging materials can extend shelf life by protecting products from external factors. While this may increase upfront costs, it can reduce long-term expenses related to product spoilage.

- Optimized Packaging Designs: Streamlining packaging designs, materials, and sizes can cut production and transportation costs while still preserving product quality. This optimization can strike a balance between shelf life extension and cost control.

- Temperature-Controlled Packaging: Employing temperature-controlled packaging is costlier but essential for certain temperature-sensitive products. It extends shelf life by preventing spoilage, ultimately reducing overall costs associated with product wastage.

- Regular Quality Control: Implementing stringent quality control measures may increase initial costs. Still, it ensures that products meet quality standards, reducing expenses tied to product recalls or customer complaints.

Navigating the Packaging Tradeoff

Striking the right equilibrium between extending shelf life and controlling costs is a nuanced endeavor, necessitating a holistic approach:

- Market Insight: Thorough market research helps businesses understand consumer preferences, demand patterns, and price sensitivity, guiding decision-making.

- Product Assessment: Recognize that different products have varying requirements. Prioritize shelf life extension for perishable goods, while focusing on cost control for less time-sensitive products.

- Continuous Optimization: Regularly assess processes, materials, and packaging to identify opportunities for cost savings without compromising product quality or shelf life.

- Adaptability: Be prepared to adapt strategies as market conditions, consumer preferences, and technological advancements evolve.

If you are interested in maximizing your packaging extended shelf-life while limiting costs, then partner with Brown Packaging today to get started.

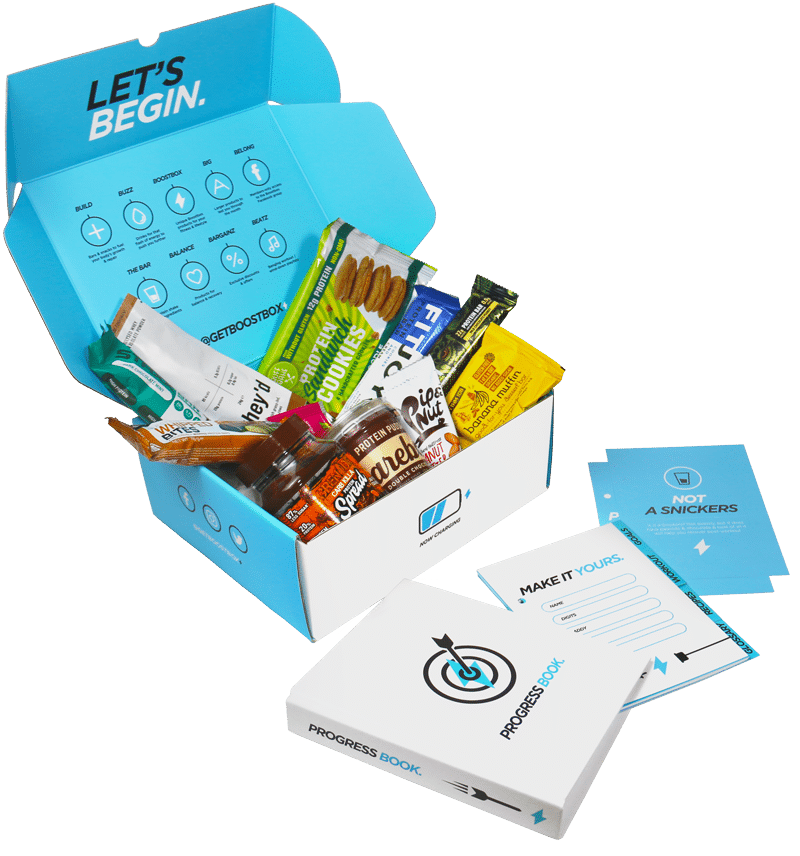

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers should review in 2026 when sourcing or redesigning subscription packaging. Branding and Unboxing Experience Seasonal or rotating graphics to keep unboxing fresh. Premium finishes such as foil, embossing, or unique die-cuts. Easy-open features like tear strips for convenience. Right-Sizing and Efficiency Reduce DIM charges with packaging tailored to product sizes. Use modular designs to cover multiple SKUs with fewer box sizes. Ensure packaging works with automation to speed fulfillment. Protection and Durability Inserts that prevent product shifting during transit. ISTA-tested designs to withstand vibration and drops. Moisture-resistant coatings for temperature-sensitive items. Sustainability Requirements FSC-certified corrugated or recycled substrates. Recyclable coatings or compostable options. Clear sustainability messaging to support consumer expectations. Cost Control SKU rationalization to limit unnecessary box variations. Material selection that balances protection and price. Supplier contracts that secure pricing for seasonal peaks. Packaging Solutions with Brown Packaging Brown Packaging designs subscription packaging that combines branding, protection, and sustainability. From FSC-certified corrugated to custom inserts, our solutions help buyers create packaging that builds loyalty and controls costs in 2026. Contact us to review your subscription packaging program. References Sustainable Packaging Coalition. (2023). Subscription Packaging and Consumer Insights. Retrieved from https://sustainablepackaging.orgForest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Ecommerce Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated customers. The key is balancing material use, box design, and supply chain efficiency so that savings do not come at the expense of protection. Where Packaging Costs Add Up Oversized boxes: Drive dimensional weight charges. Excess materials: Overuse of void fill and inserts. Complex SKU mix: Redundant sizes increase inventory costs. Inefficient freight: Poor palletization and stacking. Cost-Saving Strategies That Maintain Protection Right-sizing: Match box size to product dimensions to cut DIM charges and material use. Optimize corrugated grades: Switch to single- or double-wall where appropriate without compromising strength. Consolidate SKUs: Streamline packaging options to reduce inventory overhead. Efficient inserts: Replace foam or excess dunnage with engineered corrugated or molded pulp. Supplier contracts: Negotiate based on annual volumes, not just peak season orders. Testing Before Implementing Changes Use ASTM and ISTA protocols to ensure changes won’t increase product damage. Test for compression, vibration, and drop resistance. Run pilot shipments before scaling across the supply chain. Balancing Sustainability and Cost Eco-friendly doesn’t have to mean expensive: Use recyclable coatings to reduce plastic films. Choose corrugated designs that require less material while maintaining stacking strength. Highlight sustainable solutions in marketing to offset cost concerns. Packaging Solutions with Brown Packaging Brown Packaging helps companies lower costs while protecting products across the supply chain. From SKU rationalization to right-sized corrugated solutions, our team ensures packaging savings don’t compromise performance. Contact us to optimize your packaging program. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.Sustainable Packaging Coalition. (2023). Packaging Efficiency and Waste Reduction Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping, and automation create new challenges for packaging buyers. The right materials, testing, and design strategies are critical to protecting products while controlling costs. Why Damage Prevention Matters Financial losses: Damaged products increase replacement and freight costs. Customer impact: Poor delivery experience reduces loyalty and repeat sales. Sustainability: Returns and waste drive higher carbon footprints. Compliance: Retailers often impose penalties for damaged shipments. Common Causes of Product Damage Compression: Pallet stacking weakens boxes in transit. Vibration and shock: Long-haul shipping increases risk. Moisture exposure: Humidity and rain compromise corrugated performance. Poor right-sizing: Oversized boxes allow product movement inside. Strategies to Reduce Damage in 2026 Right-size packaging: Minimize empty space and movement. Material optimization: Choose the correct corrugated grade for load demands. Protective inserts: Molded pulp or engineered corrugated reduce shock. Moisture-resistant coatings: Defend against water and humidity. Automation-friendly design: Prevent jams that damage products on high-speed lines. Testing Protocols for Damage Prevention ISTA testing: Simulates vibration, drops, and compression. ASTM standards: Validate packaging strength and durability. Pilot shipments: Real-world trials confirm lab results. Packaging Solutions with Brown Packaging Brown Packaging designs solutions that minimize damage across today’s complex supply chains. From right-sized corrugated to ISTA-tested inserts, we help buyers protect products while reducing costs. Contact us to strengthen your packaging program. References ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Exploring Packaging Tradeoffs: Shelf-life vs. Costs

Packaging isn’t just a box or a bag—it’s a line item on your budget, a touchpoint with your customer, and a critical part of your supply chain. But what many companies don’t realize is that their packaging may be costing them more than it should—not just in materials, but in storage, shipping, damage, and customer experience. If you haven’t taken a close look at your packaging setup lately, now’s the time to assess whether it’s helping or hurting your bottom line. Oversized Packaging = Wasted Money It’s a common mistake: using a box that’s much larger than the product. Not only does this require more void fill, it also increases your dimensional shipping weight, which drives up freight costs—especially for e-commerce and parcel shipping. Solution:Switch to right-sized packaging or explore mailer alternatives like poly mailers or custom die-cut corrugated options that hug the product more closely. Over-Engineering Without Added Benefit It’s easy to assume stronger means better—but not every product needs double-wall corrugated, high-end inserts, or expensive finishes. If your packaging is doing more than it needs to, you’re likely paying for protection or features your customer doesn’t notice or value. Solution:Review your structural design and board grade. A packaging engineer can help you optimize for the product’s weight and fragility without overspending on material. Inefficient Packaging Leads to Higher Labor Costs Packaging that’s hard to assemble, overcomplicated, or inconsistent can slow down fulfillment and increase errors. Solution:Use auto-lock bottom boxes, pre-folded cartons, or streamlined assembly instructions to reduce pack time, labor cost, and error rates. Your Shipping and Fulfillment Costs Are Rising Higher freight bills or warehouse inefficiencies are often tied to inefficient packaging: oversized boxes, time-consuming assembly, or mismatched pallets. Why it matters:This is the moment to reallocate budget toward structural redesign or automation-friendly packaging that reduces labor, materials, and dimensional weight. Storage and Shipping Inefficiencies If your packaging takes up too much warehouse space or doesn’t palletize efficiently, you’re losing money in storage and shipping before a product even leaves your facility. Solution:Work with your supplier to optimize dimensions for palletization and warehouse stacking. You may be able to reduce total storage volume or fit more units per shipment. Damage and Returns Are Killing Margins If your packaging fails in transit—even occasionally—the cost of returns, replacements, and negative reviews can quickly outweigh the cost of upgrading your packaging. Solution:If you’re seeing damage or breakage rates over 1–2%, it’s time to audit your box strength, inserts, and material choices. Improving packaging here is a direct path to better margins. Missed Opportunities with Branding Generic packaging may be cheaper—but it can cost you in brand recognition, customer loyalty, and perceived value. If your packaging doesn’t reflect your product quality, customers may assume it’s lower value. Solution:Consider affordable branding upgrades like one-color flexo print, interior printing, or custom labels to make a stronger impression without blowing the budget. Final Thoughts If you’re only looking at unit cost when reviewing packaging, you’re missing the bigger picture. True packaging costs include materials, shipping, labor, storage, damage, and brand perception. Ready to find out if your packaging is costing more than it should?We’ll help you audit your current setup and identify opportunities to save money—without compromising quality, protection, or your customer experience. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

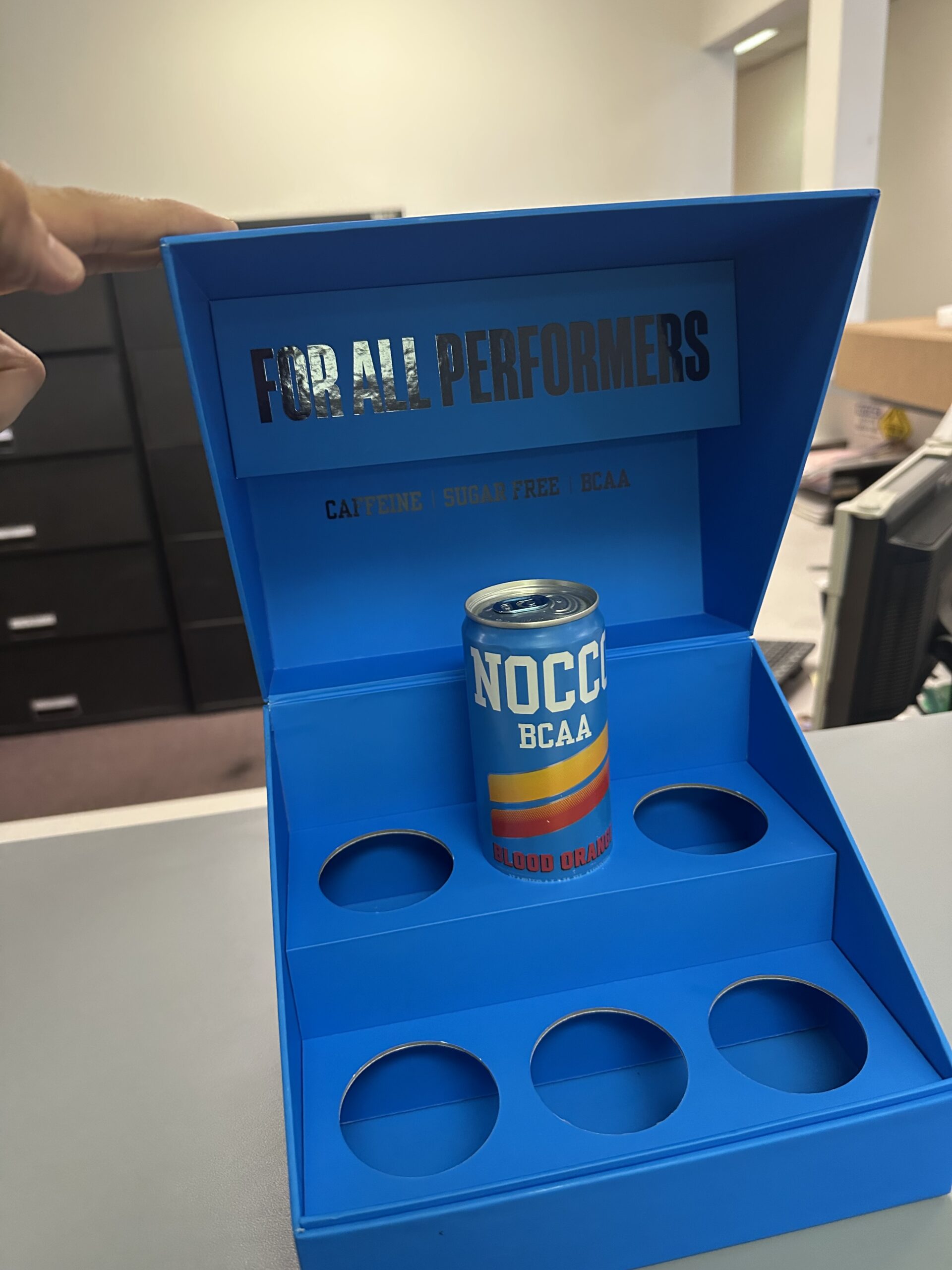

When NOCCO needed a high-end packaging solution for their influencer and investor campaign, they faced a major challenge—tight deadlines, no initial design, and the need to eliminate foam while still protecting their product. Brown Packaging stepped in, designing and delivering a custom premium rigid box with a sleek finish, innovative structural design, and secure product placement—all within just three weeks. Here’s how we made it happen. The Challenge/Problem NOCCO needed a premium packaging solution for a marketing campaign targeting social media influencers, investors, and high-value clients. However, several challenges had to be addressed: Tight Lead Time – The packaging had to be designed, tested, and produced within just three weeks. Redesign Request – The client previously had these boxes made in Europe but now needed a modified version that could hold 6 cans instead of 2—without the original basketball-themed design. Foam-Free Protection – The previous packaging relied on foam to secure the cans, but the client wanted a design that eliminated foam while still preventing damage. Impact on Their Operations Without an elevated packaging solution, the client risked missing a valuable marketing opportunity. Their standard packaging lacked the sophistication needed for this campaign, and achieving a high-end look within a short timeline was a challenge. *Images above show our clients original packaging from Europe with the foam* Solution: Brown Packaging’s Approach To meet NOCCO’s needs, Brown Packaging developed a premium custom box that improved presentation and product protection while eliminating foam inserts. The solution included:✅ Custom Structural Design – Created a two-layer shelf system that secured the cans in place while providing a tiered display.✅ Foam-Free Protection – Engineered an insert that held the cans securely, preventing movement and damage without using foam.✅ 3D Renderings & Prototypes – Provided visual concepts, plain structural samples for testing, and preliminary printed samples for approval.✅ Premium Materials & Finishes – Designed a high-end soft-touch box with Spot UV on a premium material beyond standard corrugated.✅ Custom Printed Inserts – Developed a printed insert card to enhance branding and the unboxing experience. Collaborative Process The customer sent reference samples and requested a design that held 6 cans instead of 2. Brown Packaging designed a first concept with 3D renderings, which the client approved. A structural prototype was produced and refined to eliminate foam while ensuring product protection. Artwork die lines were provided, and the client applied their graphics. Printed samples were created to verify accuracy before final production. All approvals were secured, and the final production run was completed within the three-week deadline. *Images above show a physical sample of NOCCO’s premium rigid box with a hinge and inserts* *Images above show a digital sample of NOCCO’s premium rigid box with a hinge and inserts* *Image above show NOCCO’s sent out card, which is attached to the top of the box* Implementation: Timeline & Execution Step 1: Backward planning ensured artwork deadlines aligned with production. Step 2: The Brown Packaging design team worked quickly to finalize the structure and provide die lines. Step 3: The client was highly responsive in providing artwork and approving designs, keeping the project on schedule. Challenges & Adjustments 🚧 Foam-Free Protection – The initial prototype allowed too much movement, so an additional shelf was incorporated to stabilize the cans.🚧 Box Closure Issues – Adjustments were made to ensure a clean and secure closure.🚧 Tight Timeline – Rapid approvals were required to meet the three-week deadline, but collaboration between Brown Packaging and NOCCO ensured success. Outcome: Results Premium Branding: A sleek, high-end design that enhanced NOCCO’s marketing campaign. Eliminated Foam: A sustainable and efficient structural solution without compromising product protection. On-Time Delivery: The custom packaging was designed, tested, and produced within the tight deadline. *Images above show a physical sample with print of NOCCO’s premium rigid box with a hinge and inserts* Sales Representative Contact Information Alex Vom SteegAccount Manager📧 Email: alex@brownpackaging.com📞 Phone: (714) 300-0650 Case Studies: Content Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Other Case Studies

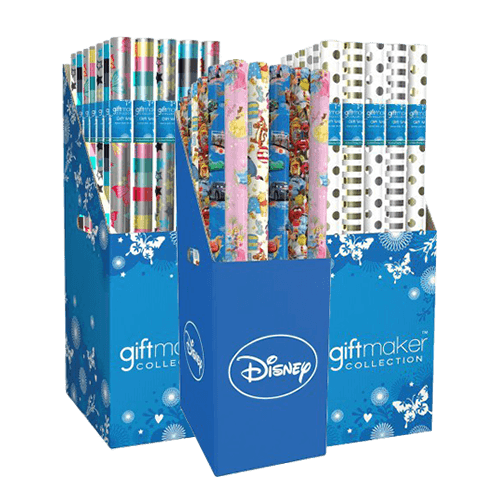

Point of Purchase (POP) displays are a crucial element in the world of retail marketing. They play a significant role in catching the eye of shoppers and encouraging impulse purchases. One specific type of POP display that’s widely used is the “Dump Bin.” In this blog, we will delve into what POP display dump bins are, their benefits, how they work, and why they are essential for retailers and brands alike. What are POP Display Dump Bins? Definition and Purpose POP display dump bins, often simply referred to as “dump bins,” are open-top containers or bins used in retail environments to display a variety of products. These bins are strategically placed throughout the store, typically near checkout counters, entrances, or high-traffic areas, to capture shoppers’ attention and promote spontaneous buying decisions. Construction and Design Dump bins come in various shapes, sizes, and materials, but they share a few common features. They are open at the top, allowing easy access to products, and they often have slanted sides for better visibility. Dump bins can be made from cardboard, plastic, wire, or even wood, depending on the retailer’s branding and the intended use. How Do Dump Bins Work? Product Placement Retailers carefully select the products they want to promote using dump bins. These products are typically smaller or lower-priced items that are ideal for impulse purchases, such as candies, small toys, or seasonal items. Strategic Placement Dump bins are strategically placed at key locations within the store. For example, near the checkout counter, customers waiting in line are more likely to make additional purchases when they see enticing items in the bin. Visual Appeal Dump bins are designed to be eye-catching. The open, inviting design allows shoppers to see the products easily. Retailers often use colorful signage, branding, and graphics to draw attention to the bin. Accessibility Dump bins are designed for convenience. Shoppers can easily reach in and grab the products they desire without the need for a shopping cart or basket. This accessibility encourages quick, spontaneous purchases. Benefits of Using Dump Bins Increased Sales Dump bins can significantly boost sales, especially for impulse-driven products. Customers who may not have originally intended to purchase these items are more likely to do so when they see them prominently displayed. Enhanced Brand Visibility Dump bins offer an excellent opportunity for brand exposure. Retailers can use these bins to showcase their branding, logos, and taglines, reinforcing their presence in the customer’s mind. Efficient Inventory Management Dump bins can help retailers move excess inventory or promote seasonal items effectively. They create a designated space for these products, preventing them from cluttering the store shelves. Customer Engagement Dump bins engage customers on a sensory level. Shoppers can touch, pick up, and examine the products in a hands-on manner, which can lead to a stronger connection with the brand. Why are Dump Bins Essential? Adaptability Dump bins are versatile and can be used across various industries and retail settings, from grocery stores to clothing boutiques. Their adaptability makes them a valuable tool for marketers. Cost-Effective Dump bins are a cost-effective way to increase sales and brand visibility without significant investments in store redesign or advertising campaigns. Encourage Impulse Buying In the world of retail, impulse purchases can make a significant impact on a business’s bottom line. Dump bins are designed to tap into this consumer behavior effectively. Enhanced Shopping Experience By providing customers with an enjoyable and interactive shopping experience, dump bins contribute to overall customer satisfaction and loyalty. If you are interested in POP display dump bins, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts