Home » 10 Ways to Maximize the Presentation of Your RETT Boxes

10 Ways to Maximize the Presentation of Your RETT Boxes

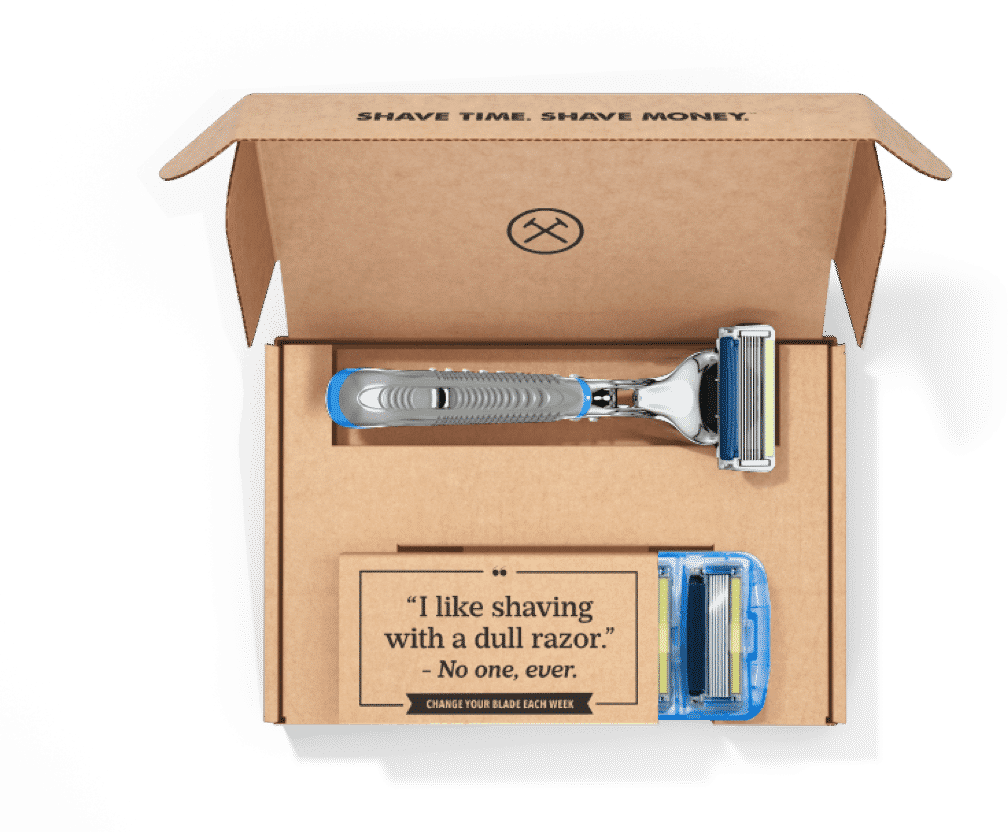

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression. Roll End Tuck Top (RETT) boxes, known for their durability and versatility, provide an excellent canvas to enhance the presentation of your products.

In this detailed blog, we will explore 12 effective strategies and tips on how to maximize the presentation of your RETT boxes to create a memorable unboxing experience for your customers.

Creative Branding

Utilize the ample space on RETT boxes for creative branding. Include your company logo, eye-catching graphics, and product information. A well-designed box instantly communicates your brand identity and sets the tone for the unboxing experience.

Custom Printing

Invest in high-quality custom printing to ensure that your RETT boxes are visually striking. Vibrant colors and sharp imagery can make your packaging stand out and pique the customer’s interest.

Consistency Across Products

Maintain consistency in your packaging design across different products or product lines. A cohesive look reinforces your brand and makes your products easily recognizable.

Window Inserts

Consider adding window inserts to your RETT boxes. These transparent openings allow customers to preview the product inside, adding intrigue and enticing them to open the box.

Custom Die-Cut Shapes

Opt for custom die-cut shapes for your RETT boxes to make them unique and attention-grabbing. Unconventional shapes can make your packaging more memorable.

Matte or Glossy Finish

Choose between matte and glossy finishes to complement your brand’s aesthetics. Matte finishes exude sophistication, while glossy finishes provide a polished and vibrant look.

Branding Inside the Box

Don’t neglect the interior of your RETT boxes. Adding branding elements, messages, or design accents inside the box enhances the overall unboxing experience and surprises customers.

Personalized Touch

Consider adding a personalized touch, such as a handwritten thank-you note or a small promotional item, to show appreciation to your customers and leave a positive impression.

Seasonal or Limited-Edition Packaging

For special occasions or limited-edition products, create seasonal or unique packaging designs. These limited runs can generate excitement and encourage purchases.

Professional Photography

When showcasing your products online or in marketing materials, use professional photography to highlight the packaging’s visual appeal and its role in enhancing the product presentation.

Conclusion

Maximizing the presentation of your RETT boxes involves careful consideration of design, materials, and branding. These packaging strategies can significantly impact the customer’s perception of your products and brand. By investing in creative design, custom printing, and unique features, you can create a memorable unboxing experience that leaves a lasting impression on your customers, ultimately contributing to increased brand loyalty and customer satisfaction.

If you are interested in roll end tuck top boxes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » 10 Ways to Maximize the Presentation of Your RETT Boxes

As the holiday season approaches, the world of e-commerce gears up for a surge in online shopping. With changing consumer behaviors and heightened expectations, brands

The Edge Crush Test (ECT) is a critical performance metric for corrugated boxes, directly correlating to stacking strength and load-bearing capacity. In the high-stress world

A Full Overlap (FOL) box is a type of corrugated shipping box where the flaps fully overlap each other when closed, providing additional strength and