Home » What Packaging is Used for Protein Bars?

What Packaging is Used for Protein Bars?

Protein bars are a popular on-the-go snack, requiring durable, protective, and visually appealing packaging to ensure freshness and convenience. The right packaging helps extend shelf life, maintain texture, and protect against contamination, making it essential for both retail and eCommerce sales. Businesses must carefully select the best materials and formats for their protein bars to optimize product protection and brand visibility.

Types of Packaging for Protein Bars

Protein bars can be packaged in various materials and formats depending on brand preference, shelf life requirements, and distribution channels. The most common types include:

Flexible Film Packaging (Flow Wraps & Roll Stock)

Flow wrap packaging, often produced from roll stock, is the most widely used solution for protein bars due to its lightweight, cost-effectiveness, and superior protection. It consists of a plastic or foil-based flexible film, heat-sealed to create an air-tight package.

Benefits:

- Provides moisture and oxygen barrier to extend shelf life.

- Offers high-speed packaging efficiency for mass production.

- Allows for vibrant branding and print customization.

Stand-Up Pouches and Resealable Bags

Ideal for multi-pack protein bars, stand-up pouches provide convenience and branding appeal while protecting bars from crushing and environmental factors.

Benefits:

- Resealable options improve freshness and portion control.

- Provides a premium look for retail shelves and club store formats.

- Customizable with clear windows, matte or gloss finishes, and tear notches.

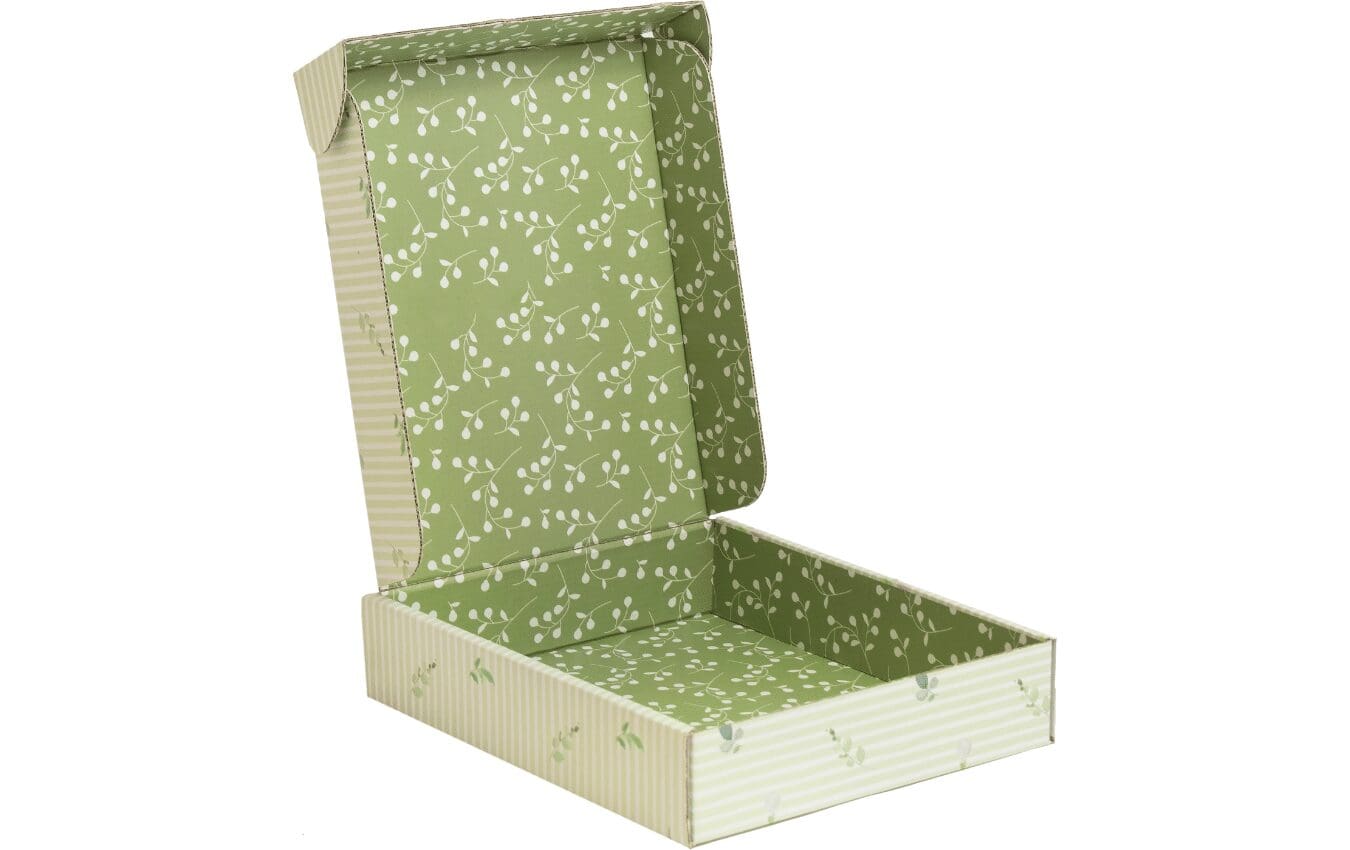

Folding Cartons

Many protein bars are sold in multi-bar packs housed in folding cartons. These secondary packaging solutions enhance shelf presence and provide additional protection.

Benefits:

- Ideal for bulk packaging and organized retail display.

- Supports branding with high-quality printing and embossing options.

- Adds structural protection to prevent crushing.

Corrugated Boxes for Shipping

For wholesale distribution and eCommerce fulfillment, protein bars are often packed in corrugated shipping boxes to ensure safe transit and bulk handling.

Benefits:

- Provides durability for long-distance shipping and warehouse storage.

- Can be designed with custom inserts for product security.

- Custom printing allows for branded unboxing experiences.

POP and Countertop Displays

Retailers often use point-of-purchase (POP) and countertop displays to showcase protein bars in high-traffic areas. These displays help drive impulse purchases and enhance brand visibility.

Benefits:

- Designed for maximum visibility in checkout lanes and retail aisles.

- Can be customized for seasonal promotions or new product launches.

- Available in corrugated or folding carton formats for easy setup.

Key Packaging Considerations for Protein Bars

Choosing the right protein bar packaging requires evaluating several factors:

- Shelf Life Protection: Packaging must offer barrier properties against moisture, air, and light to prevent spoilage.

- Consumer Convenience: Features like resealable closures, easy-open tear notches, and portability enhance the user experience.

- Branding & Marketing Appeal: High-quality printing, embossing, or matte/gloss finishes make a product stand out on retail shelves.

- Shipping & Retail Optimization: Bulk packaging and display solutions improve storage, handling, and in-store presentation.

Final Thoughts: Selecting the Best Protein Bar Packaging

Protein bar packaging should be protective, convenient, and visually appealing while aligning with industry requirements. Whether using flow wraps and roll stock for single bars, folding cartons for multi-packs, corrugated boxes for shipping, or POP displays for retail, businesses should evaluate their packaging based on functionality, branding, and distribution needs.

Looking for custom protein bar packaging solutions? Contact Brown Packaging today to explore innovative packaging options that meet your brand’s needs!

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » What Packaging is Used for Protein Bars?