Home » Understanding Polyethylene Foam In Packaging

Understanding Polyethylene Foam In Packaging

Packaging plays a crucial role in protecting products during transit and storage. Among the various materials used for packaging, polyethylene foam stands out as an excellent choice due to its unique combination of properties that make it ideal for cushioning and protecting a wide range of items. In this comprehensive guide, we will explore everything you need to know about polyethylene foam for packaging.

What is Polyethylene Foam?

Polyethylene foam is a lightweight material made from polyethylene, a type of plastic. It is characterized by its high resilience, flexibility, and excellent cushioning properties. Polyethylene foam is commonly used in various industries, including automotive, electronics and aerospace.

Key Properties of Polyethylene Foam

Polyethylene foam’s popularity in packaging is attributed to several key properties:

Cushioning and Shock Absorption

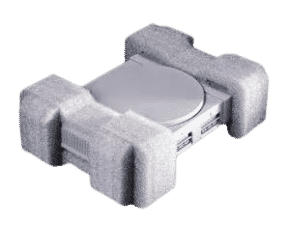

One of the primary reasons for using polyethylene foam in packaging is its exceptional cushioning and shock-absorbing capabilities. The structure of the foam allows it to compress and absorb impact energy, protecting delicate or fragile items from damage during handling and transportation.

Lightweight

Polyethylene foam is lightweight, making it an ideal choice for reducing shipping costs while still providing adequate protection. Its low weight-to-volume ratio is advantageous for both the manufacturer and the end consumer.

Water Resistance

Polyethylene foam is resistant to moisture and water, which helps protect products from water damage during transit or storage. This property is particularly important for items that are sensitive to moisture.

Chemical Resistance

Polyethylene foam is also resistant to many chemicals, oils, and solvents, making it suitable for packaging items that may come into contact with these substances.

Durability

Polyethylene foam is durable and long-lasting, ensuring that it can withstand the rigors of the packaging and shipping process. It does not easily tear, puncture, or break down over time.

Thermal Insulation

While not as efficient as some other insulating materials, polyethylene foam provides a degree of thermal insulation, helping to protect products from temperature fluctuations during transportation and storage.

Types of Polyethylene Foam

Polyethylene foam comes in various forms, each tailored to specific packaging needs:

Plank Foam

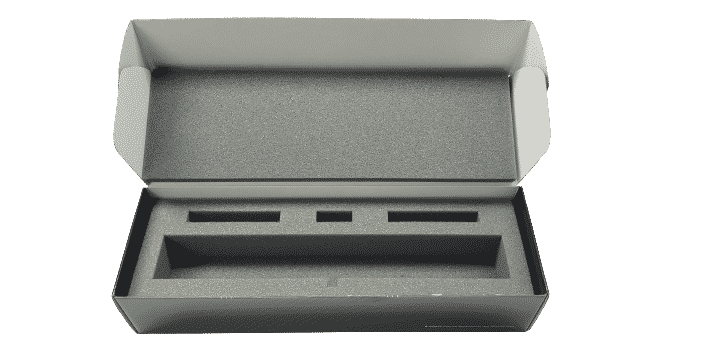

Plank foam is a solid sheet of polyethylene foam available in various thicknesses. It is often used for cushioning, interleaving, and lining packaging boxes.

Roll Foam

Roll foam is a continuous roll of polyethylene foam, which can be easily cut to the desired length. It is commonly used for wrapping and protecting fragile items.

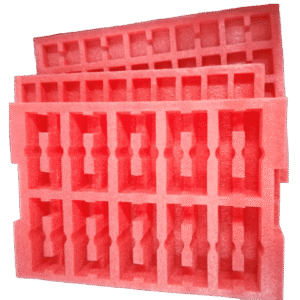

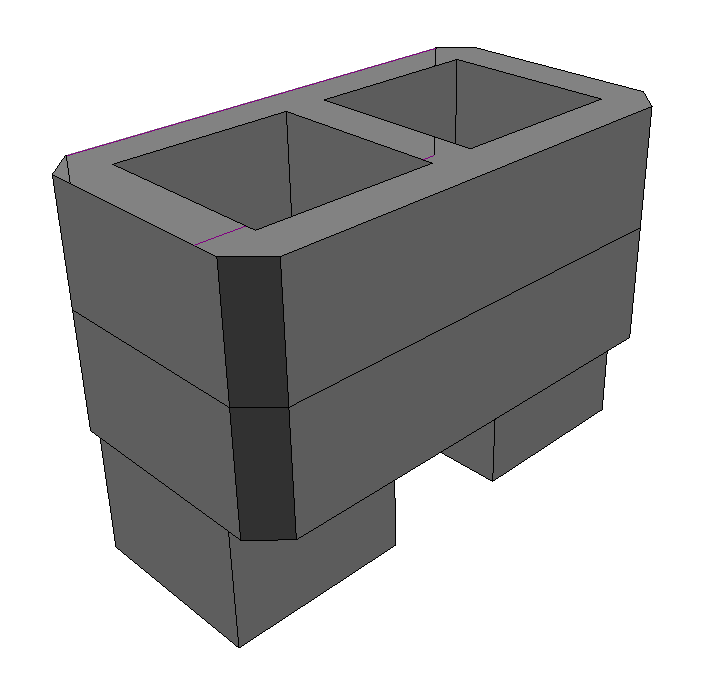

Die-Cut Foam

Die-cut foam refers to polyethylene foam sheets that have been cut into specific shapes or profiles to fit the contours of a product precisely. This customized approach provides optimal protection for irregularly shaped items.

Anti-Static Foam

For packaging sensitive electronic components, anti-static polyethylene foam is available. It prevents electrostatic discharge (ESD) that can damage sensitive electronics.

Common Applications of Polyethylene Foam in Packaging

Polyethylene foam finds applications in a wide range of industries and packaging scenarios, including:

Electronics Packaging

Polyethylene foam is commonly used to protect electronic components, such as circuit boards, computer equipment, and delicate sensors, from shock and ESD during transportation.

Automotive Packaging

In the automotive industry, polyethylene foam is used to protect fragile automotive parts, prevent damage to painted surfaces, and reduce noise and vibration during transit.

Medical Equipment Packaging

Sensitive medical equipment, instruments, and devices are often packaged using polyethylene foam to ensure they reach their destination in pristine condition.

Glassware and Dishware Packaging

Fragile glassware, ceramics, and dishware benefit from polyethylene foam’s cushioning properties, preventing breakage and chipping.

Furniture Packaging

Polyethylene foam is used to protect furniture pieces like tables, chairs, and glass tabletops from scratches and damage during shipping.

Aerospace Packaging

In the aerospace industry, where precision and safety are paramount, polyethylene foam is used to protect critical components and equipment during transportation and storage.

Choosing the Right Polyethylene Foam for Your Packaging Needs

Selecting the appropriate polyethylene foam for your packaging requirements is crucial. Consider the following factors:

Thickness

Choose the foam thickness based on the fragility of the item you’re packaging. Thicker foam provides better cushioning for delicate items.

Density

The foam’s density affects its compression and cushioning abilities. Higher-density foam offers greater protection but may be heavier and more expensive.

Type

Select the right type of polyethylene foam (plank, roll, die-cut, or anti-static) depending on your packaging needs and the nature of the items you’re shipping.

Customization

For irregularly shaped items or unique packaging requirements, consider custom die-cut foam for a tailored solution.

If you are interested in polyethylene foam, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Understanding Polyethylene Foam In Packaging

Packaging is not merely a practical aspect of shipping; it’s also a statement about your brand’s commitment to quality and protection. When it comes to

When working with thick foam materials in the packaging industry, it’s important to be aware of the natural outcomes of the die-cutting process—one of the

When it comes to protecting fragile or valuable items during shipping or storage, the choice of packaging material can make all the difference. Polyurethane foam