Home » Top Printing Methods and Finishes for Rigid Boxes

Top Printing Methods and Finishes for Rigid Boxes

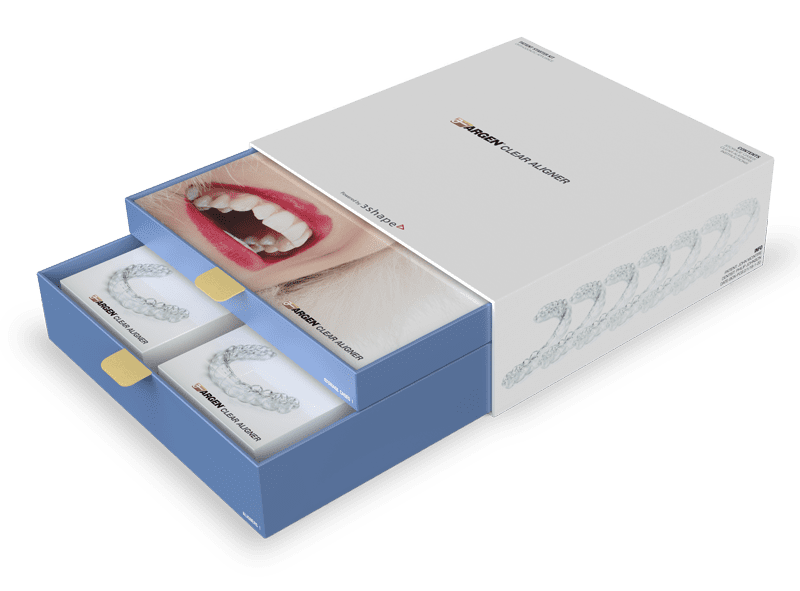

Rigid boxes are known for their premium feel, durability, and high-end presentation, making them the go-to choice for luxury goods, cosmetics, electronics, and gift packaging. But what really sets a rigid box apart isn’t just its structure—it’s the printing and finishing.

Whether you’re aiming for elegance, bold visuals, or a tactile unboxing experience, the right combination of print method and finishing technique is key to bringing your packaging to life.

Here’s a breakdown of the most popular options and what you should know about each.

Most Common Printing Methods for Rigid Boxes

Lithographic (Offset) Printing

This is the most popular method for rigid boxes, offering high-resolution, full-color prints with sharp detail and excellent consistency.

Best For:

- Retail and luxury branding

- Cosmetics, electronics, and fashion

- Complex, photo-quality graphics

Pros:

✔ Sharp, clean visuals

✔ Perfect for detailed or high-color designs

✔ Supports all major finishes (emboss, foil, etc.)

Digital Printing

A growing option for short runs and fast turnarounds, digital printing allows direct-to-substrate printing without the need for plates.

Best For:

- Personalized or versioned packaging

- Low to mid-quantity runs

- Limited editions or fast product launches

Pros:

✔ No plate/setup fees

✔ Great for multi-SKU designs

✔ Fast turnaround for samples and full runs

Screen Printing

Used selectively for rigid boxes, screen printing offers rich, opaque color—especially for specialty applications like matte white on dark backgrounds or bold, single-color graphics.

Best For:

- Minimalist designs

- Bold spot colors

- Specialty textures

Pros:

✔ Vibrant, high-opacity ink

✔ Good for metallics or spot finishes

✔ Works well with textured materials

Hot Stamping (Foil Stamping)

Hot stamping uses heat and pressure to apply metallic or pigmented foil onto the box, creating eye-catching, reflective accents.

Best For: Logos, monograms, premium accents

Pros:

✔ Adds visual and tactile impact

✔ Available in metallics, holographics, and pigment foils

✔ Often used with embossing for layered effects

Popular Finishes for Rigid Boxes

Printing sets the tone, but finishing brings the texture, shine, and impact. Here are the most common enhancements used to make rigid boxes stand out:

Matte and Gloss Lamination

These are protective film coatings added after printing that affect the look and feel of the box.

- Matte: Soft, elegant, non-reflective

- Gloss: Shiny, vibrant, enhances color contrast

Application: Cosmetics, tech, fashion, lifestyle products

Soft-Touch Coating

This ultra-smooth finish adds a velvety, premium texture. Often paired with minimalistic designs or foil accents for a luxury effect.

Application: High-end electronics, skincare, subscription boxes

Foil Stamping

Foil stamping uses heat and pressure to apply metallic foil (gold, silver, copper, holographic) to the box surface.

Application: Logo treatments, luxury branding, gift sets

Popular Foil Colors: Gold, silver, rose gold, holographic

Embossing & Debossing

- Embossing raises elements of the design above the surface

- Debossing presses them into the surface for a recessed effect

Often used with logos, borders, or typography to create tactile contrast and brand emphasis.

Spot UV Coating

This clear, glossy coating is applied only to specific areas—like logos, text, or imagery—to create visual contrast against a matte background.

Application: Branding elements, accent graphics, bold visual focal points

Linen, Leather, or Specialty Wraps

Beyond printing, rigid boxes can be wrapped in textured papers, leather-like materials, or specialty stocks for a distinctive tactile experience.

Application: Jewelry, spirits, promotional packaging

What to Consider When Choosing Print & Finish

- Brand identity: Do you want luxurious, modern, bold, or minimal?

- Product category: Cosmetics, tech, and fashion all have different packaging cues.

- Volume and budget: Offset is great for large runs, while digital suits smaller ones.

- Timeline: Some finishes add production time—factor that into your launch.

- Retail vs. e-commerce: Will customers see the box on a shelf or open it at home?

Final Thoughts

Rigid boxes are already associated with premium quality—but pairing the right printing method with thoughtful finishes takes them to the next level. Whether you’re going for classic elegance or modern minimalism, the combination of design, texture, and detail will shape how customers perceive your product before they even open it.

Need help selecting the right print and finish for your rigid box?

We’ll help you build a packaging solution that reflects your brand and stands out with purpose.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient fulfillment. Packaging must balance branding,

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s market, affordability has become a

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the team knew the pouch size

Home » Top Printing Methods and Finishes for Rigid Boxes