Home » Top 10 Reasons to Consider Blister Packaging for Your Products

Top 10 Reasons to Consider Blister Packaging for Your Products

Effective packaging plays a crucial role in product presentation and protection across various industries. Among the many packaging options available, blister packaging stands out as a versatile and valuable choice. Blister packs find widespread use in sectors such as pharmaceuticals, electronics, toys, and consumer goods.

In this comprehensive guide, we’ll delve into the top 10 reasons why blister packaging should be a strong consideration for your product packaging needs.

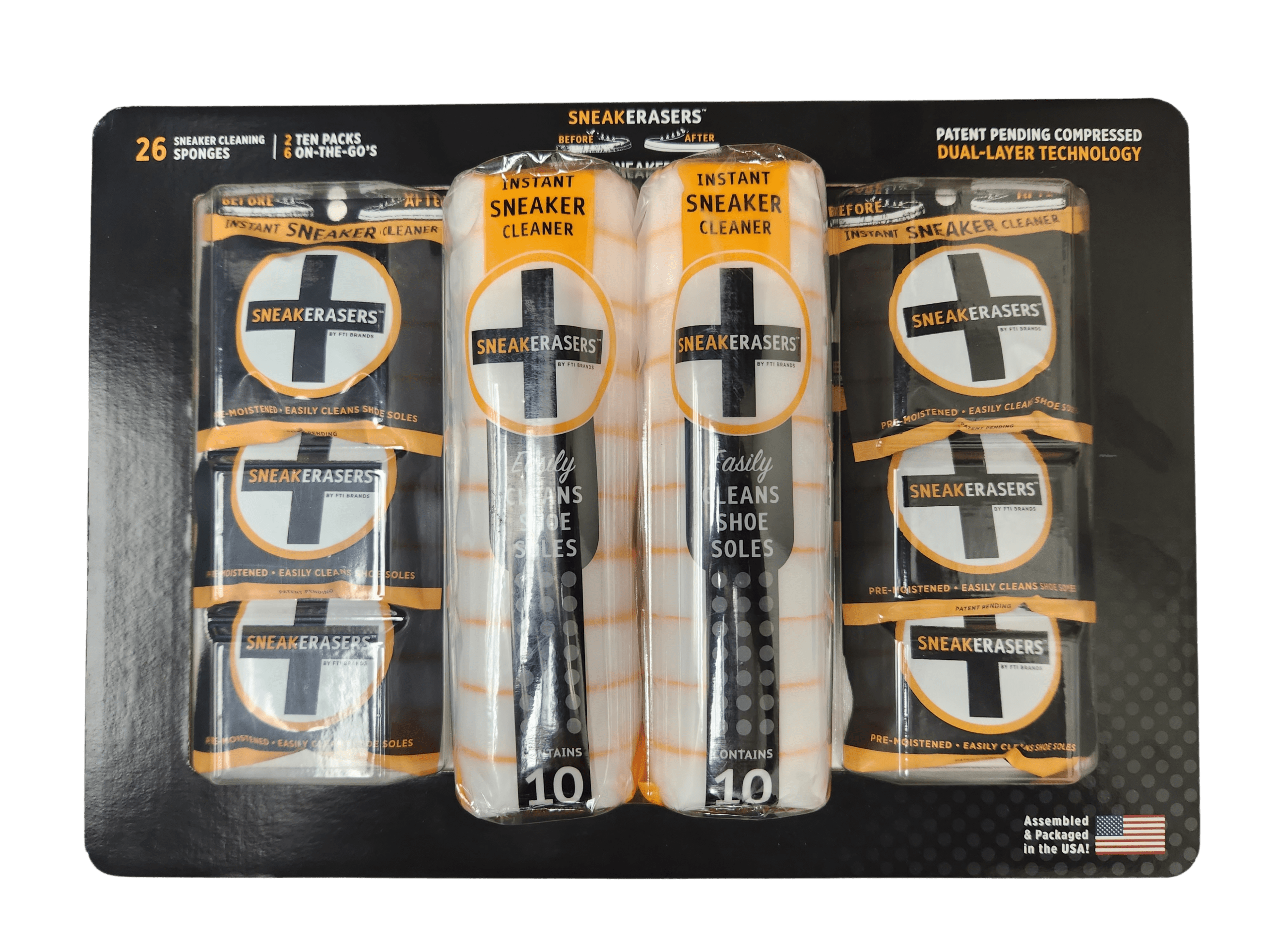

Enhanced Product Visibility

Blister packaging excels in showcasing your product. Its transparent plastic shell offers a clear view of the item within. This visibility builds consumer trust and confidence as customers can precisely see the product they are purchasing, reducing the likelihood of misunderstandings or dissatisfaction.

Reliable Protection from Contamination

One of the primary advantages of blister packs is their superior protection against external contaminants. The sealed plastic shell encases the product securely, shielding it from dust, moisture, and handling. This ensures that your product remains clean and intact until it is opened by the end-user.

Tamper-Evident Features

Blister packaging can be designed to incorporate tamper-evident features, such as perforated edges or prominently printed warnings. These elements reassure customers that the product has not been tampered with, enhancing safety and trust in your brand.

Extensive Customization Options

Blister packs offer ample room for customization. You can tailor the packaging to precisely fit the shape and size of your product, allowing you to add branding elements, labels, or eye-catching graphics. This level of customization creates a unique and visually appealing presentation that sets your product apart.

Exceptional Durability

Blister packs are renowned for their durability. They can withstand the rigors of handling, transportation, and storage. The robust plastic shell resists tearing, ensuring that your products reach customers in excellent condition.

Cost-Effective Solution

Blister packaging is often a cost-effective choice, particularly for high-volume production. The efficiency of the packaging process and material options can help reduce overall packaging costs while maintaining quality.

Space Efficiency

Blister packs are space-efficient, making them ideal for retailers and businesses with limited shelf or storage space. The compact design allows for easy stacking and storage, optimizing space usage.

Sustainability Considerations

Blister packaging can be designed with sustainability in mind. Many blister pack materials are recyclable, contributing to eco-friendly packaging practices. By choosing sustainable options, you can reduce your environmental footprint and appeal to environmentally conscious consumers.

Shelf Life Extension

Blister packs can be designed to extend the shelf life of products that require protection from moisture, light, or oxygen. This is particularly crucial for industries such as pharmaceuticals and food, where product freshness and integrity are paramount.

Versatile Packaging Solution

Blister packaging’s versatility is one of its standout features. It is suitable for a wide range of products, spanning pharmaceuticals, cosmetics, small electronics, hardware, and more. Its adaptability and compatibility with diverse product types make it a popular choice across various industries.

Blister packaging offers a multitude of advantages, making it an attractive and versatile option for product packaging. Its transparency, contamination protection, tamper-evident features, customization possibilities, durability, cost-effectiveness, and space efficiency are some of the key reasons businesses opt for blister packaging. Additionally, blister packs can contribute to sustainability goals, extend product shelf life, and accommodate a wide array of products. Whether you operate in the pharmaceutical, electronics, or consumer goods industry, exploring the benefits of blister packaging can enhance your product’s appeal, protection, and marketability.

If you are interested in blister packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Top 10 Reasons to Consider Blister Packaging for Your Products