Home » The Art and Science of Corrugated Box Design

The Art and Science of Corrugated Box Design

Corrugated boxes are a ubiquitous part of our daily lives, used for packaging and shipping a wide variety of products. While they may seem simple on the surface, there is a remarkable blend of art and science involved in their design. A well-designed corrugated box ensures that products are protected during transit, minimizes material waste, and enhances the overall packaging experience. In this comprehensive guide, we will delve into the world of corrugated box design, exploring the artistry and scientific principles behind it.

Understanding Corrugated Fiberboard

Before diving into box design, it’s important to understand the material at its core: corrugated fiberboard. This versatile material consists of three layers: two flat linerboards on the outer surfaces and a wavy or fluted medium sandwiched between them. The fluted medium provides strength and rigidity, while the linerboards offer protection and a printable surface for branding and labeling.

The Functionality of Corrugated Boxes

The primary function of a corrugated box is to protect its contents during transit. However, the design must also consider factors such as cost-effectiveness, sustainability, and ease of handling. Let’s explore the various aspects that contribute to the functionality of corrugated boxes.

- Structural Integrity: The box must be structurally sound to withstand stacking, impact, and other stresses encountered during shipping. The arrangement and dimensions of flutes, the selection of linerboard thickness, and appropriate adhesive bonding all play a crucial role in ensuring the box’s strength.

- Stackability and Compression Strength: Corrugated boxes are often stacked on pallets during storage and transportation. A well-designed box should have sufficient compression strength to withstand the weight of other boxes stacked on top without collapsing or deforming.

- Cushioning and Protection: The box should provide adequate cushioning to protect the product from shocks, vibrations, and potential damage during transit. This can be achieved through the use of internal supports such as partitions, inserts, or foam padding.

- Ergonomics and Handling: The design should consider ease of handling for both workers and end-users. Factors like handholds, perforations for easy opening, and appropriate sizing contribute to a positive user experience.

- Sustainability: With growing environmental concerns, sustainable packaging is gaining prominence. Design considerations such as material selection, optimizing box dimensions to minimize waste, and incorporating recyclable or biodegradable materials contribute to a greener packaging solution.

Box Design Considerations

Designing a corrugated box involves a balance between functionality, aesthetics, and efficiency. Here are key considerations to keep in mind when embarking on the design process.

- Product Specifications: The dimensions, weight, fragility, and shape of the product being packaged influence the box design. It’s crucial to accurately measure and understand these specifications to ensure a well-fitted and protective box.

- Box Style Selection: Various box styles, such as regular slotted containers (RSCs), die-cut boxes, and telescopic boxes, cater to different product requirements. Choosing the appropriate box style influences factors such as ease of assembly, stackability, and presentation.

- Flute Selection: Corrugated fiberboard comes in different flute profiles, including A, B, C, E, and F. Each flute type offers specific strength and cushioning properties. Selecting the right flute profile based on the product’s fragility and weight is essential for optimal protection.

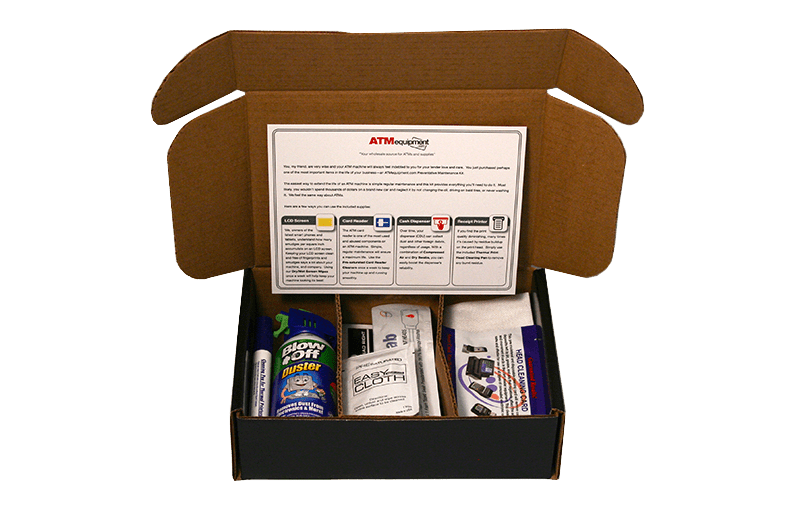

- Graphics and Branding: Corrugated boxes provide a valuable branding opportunity. Consider incorporating visually appealing graphics, logos, and other branding elements on the box surface to enhance the overall product presentation and create a memorable unboxing experience for the customers.

- Material Selection: The choice of linerboard material affects both the box’s strength and its visual appeal. Factors such as recycled content, virgin fibers, and the overall quality of the linerboard must be considered. Additionally, selecting the appropriate adhesive for bonding the layers is crucial for maintaining box integrity.

- Structural Design: The structural design of the box involves determining the dimensions, fluting orientation, and reinforcements required for optimal strength. Computer-aided design (CAD) software and structural analysis tools can aid in creating efficient and robust box designs.

- Testing and Prototyping: Before mass production, it’s essential to test and prototype the box design to ensure its functionality. Physical or virtual testing methods can evaluate the box’s performance under various conditions, such as drop tests, compression tests, and vibration tests.

- Supply Chain Considerations: The design should also take into account factors such as efficient storage, transportation, and stacking within the supply chain. Optimizing box dimensions to maximize space utilization and minimize transportation costs is an important consideration.

Innovation in Corrugated Box Design

The world of corrugated box design is constantly evolving, driven by advancements in technology and changing consumer demands. Innovations in this field aim to enhance functionality, sustainability, and user experience. Here are a few notable innovations in corrugated box design:

- E-commerce Packaging Solutions: With the exponential growth of online shopping, e-commerce packaging has become a focus of innovation. Designs that offer easy opening, customized printing for branding, and secure protection for products are key considerations in this area.

- Smart Packaging: Integration of technology into corrugated boxes opens up possibilities for smart packaging solutions. RFID tags, QR codes, or other tracking mechanisms can provide real-time information about the package’s location, handling, and condition.

- Bio-based Materials: Researchers are exploring bio-based alternatives to traditional corrugated materials, such as bio-based adhesives and coatings, as well as biodegradable or compostable fiberboards. These materials offer increased sustainability and reduced environmental impact.

- Intelligent Packaging Design: Designers are incorporating features such as perforations, tear strips, and resealable elements into box designs, enhancing user convenience and reusability.

If you are interested in custom corrugated boxes, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » The Art and Science of Corrugated Box Design

Ecommerce packaging is more than just a protective shell for your products; it’s a canvas for your brand identity, a vessel for customer experience, and

The longevity of corrugated boxes, a question frequently asked by businesses and consumers alike, hinges on several key factors, including their construction, material quality, and

Full-Overlap (FOL) boxes are renowned for their structural integrity and robust design, making them a popular choice for packaging products that require extra protection during