Home » Roll Stock vs. Pouches: Comparing Flexible Packaging Options

Roll Stock vs. Pouches: Comparing Flexible Packaging Options

Packaging plays a crucial role in marketing a product. The packaging material and design not only protect the product but also influence the customer’s purchasing decision. Roll stock and pouches are two popular types of flexible packaging used widely across various industries. In this blog post, we will dive deeper into roll stock and pouches and compare and contrast them to help you decide which one is the best option for your packaging needs.

What is Roll Stock?

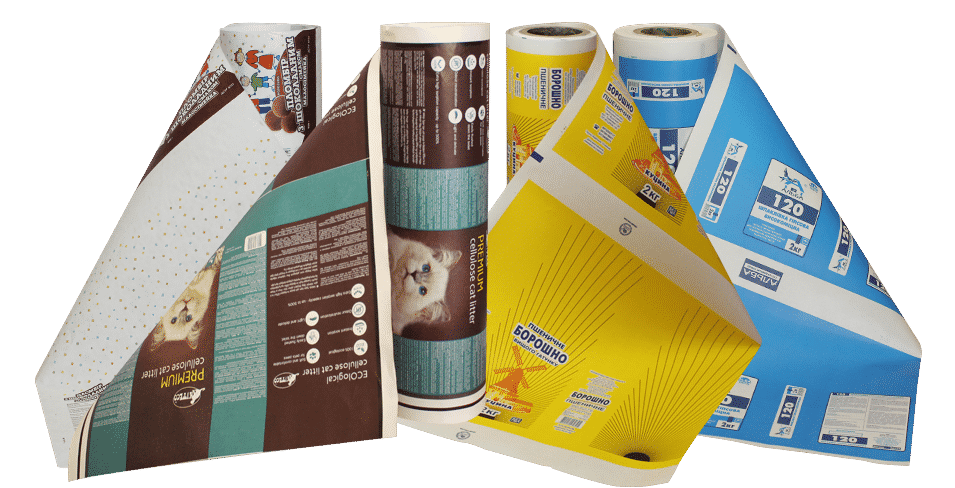

Roll stock, also known as roll-fed packaging, is a type of flexible packaging material that comes in a roll form. It is commonly made of plastic materials such as polypropylene, polyethylene, and polyester. Roll stock is a popular choice for packaging products such as snacks, pet food, candy or similar products.

Roll stock can be customized to meet the specific needs of a product. It can be printed with high-quality graphics, which is great for branding and marketing purposes. Roll stock can also be made in different sizes, thicknesses, and colors to suit different packaging requirements.

Roll stock is produced in large rolls and then cut and formed into the final shape by the packaging manufacturer or co-packer. The manufacturing process is cost-effective, making it a good choice for companies looking to save money on packaging costs. Roll stock takes up less storage space than pre-made pouches because it is produced in large rolls. This makes it easier to store and transport.

What are Pouches?

Pouches, also known as pre-made bags, are another popular type of flexible packaging. Unlike roll stock, pouches are pre-made and come in various sizes, shapes, and styles. They are commonly made of materials such as plastic films, laminates, and aluminum foil.

Pouches can be customized with high-quality graphics and designs, making them a popular choice for branding and marketing purposes. They are used to package a wide range of products such as supplements, powders, foods, beverages and personal care items.

Pouches are made by sealing the edges of pre-made bags to create a sealed container. This process creates a tight seal that prevents air and moisture from entering the package, providing better product protection than roll stock. However, because pouches are pre-made and come in standard sizes and shapes, they can be more expensive than roll stock.

Differences between Roll Stock and Pouches

Here are the key differences between roll stock and pouches:

Manufacturing Process

Roll stock is produced in large rolls and then cut and formed into the final shape by the packaging manufacturer or co-packer. Pouches, on the other hand, are pre-made and formed into the final shape during the manufacturing process. Roll stock require either vertical or horizontal 4-fill seal machine also known as a vertical or horizontal wrapper.

Size and Shape

Roll stock can be made in any size or shape, depending on the product’s packaging requirements. Pouches, on the other hand, come in standard sizes and shapes.

Printing

Roll stock offers more flexibility when it comes to printing. The entire surface of the roll stock can be printed with high-quality graphics, while pouches have limited space for printing.

Cost

Roll stock tends to be more cost-effective than pouches because it is produced in bulk and is customizable. Pouches, on the other hand, are pre-made in stock and come in standard sizes and shapes, custom pouches can be made for specific sizes, making them more expensive.

Storage Space

Roll stock takes up less storage space than pouches because it is produced in large rolls, while pouches take up more storage space because they are pre-made and cannot be stacked.

Product Protection

Pouches provide better product protection than roll stock because they are pre-made and have sealed edges that prevent air and moisture from entering the package.

Which One Should You Choose?

Both roll stock and pouches have their advantages and disadvantages. The choice ultimately depends on the specific needs of your product.

Roll stock is a good choice if you need a flexible packaging material that can be customized in terms of size, shape, and printing. It is also cost-effective and takes up less storage space, making it a good choice for companies with limited storage capacity. Roll stock is ideal for products that don’t require a specific shape or size and don’t need the extra protection provided by a pre-made pouch.

Pouches, on the other hand, provide better product protection and are a good choice for products that are sensitive to air and moisture. They are also a good choice for products that require a specific size or shape. Pouches are an excellent option for products that need to stand out on shelves and grab the attention of customers due to their customizable printing options.

When deciding which packaging material to use, consider factors such as cost, size, shape, printing, and product protection.

If you are interested in roll stock, pouches or other flexible packaging, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Roll Stock vs. Pouches: Comparing Flexible Packaging Options

Flexible packaging is in the throes of a revolution, with several innovative materials surfacing that promise to change the landscape of the industry. Traditionally, flexible

The journey of creating a compelling flexible packaging design starts with gaining insight into your target demographic. Thoroughly understand their needs, preferences, and factors that

Poly bags are a staple in the packaging industry, offering a lightweight, cost-effective, and versatile solution for packaging various products, from food and consumer goods