Home » Roll Stock Flow Wrap Packaging Explained

Roll Stock Flow Wrap Packaging Explained

Roll stock flow wrap packaging is a versatile and efficient method used in the food and packaging industry to package a wide variety of products. It’s commonly used for packaging items like candy bars, cookies, granola bars, crackers, and even non-food items like soap bars and disposable razors. In this blog, we will delve into what roll stock flow wrap packaging is, how it works, its advantages, and some key considerations for businesses looking to implement this packaging solution.

What is Roll Stock Flow Wrap Packaging?

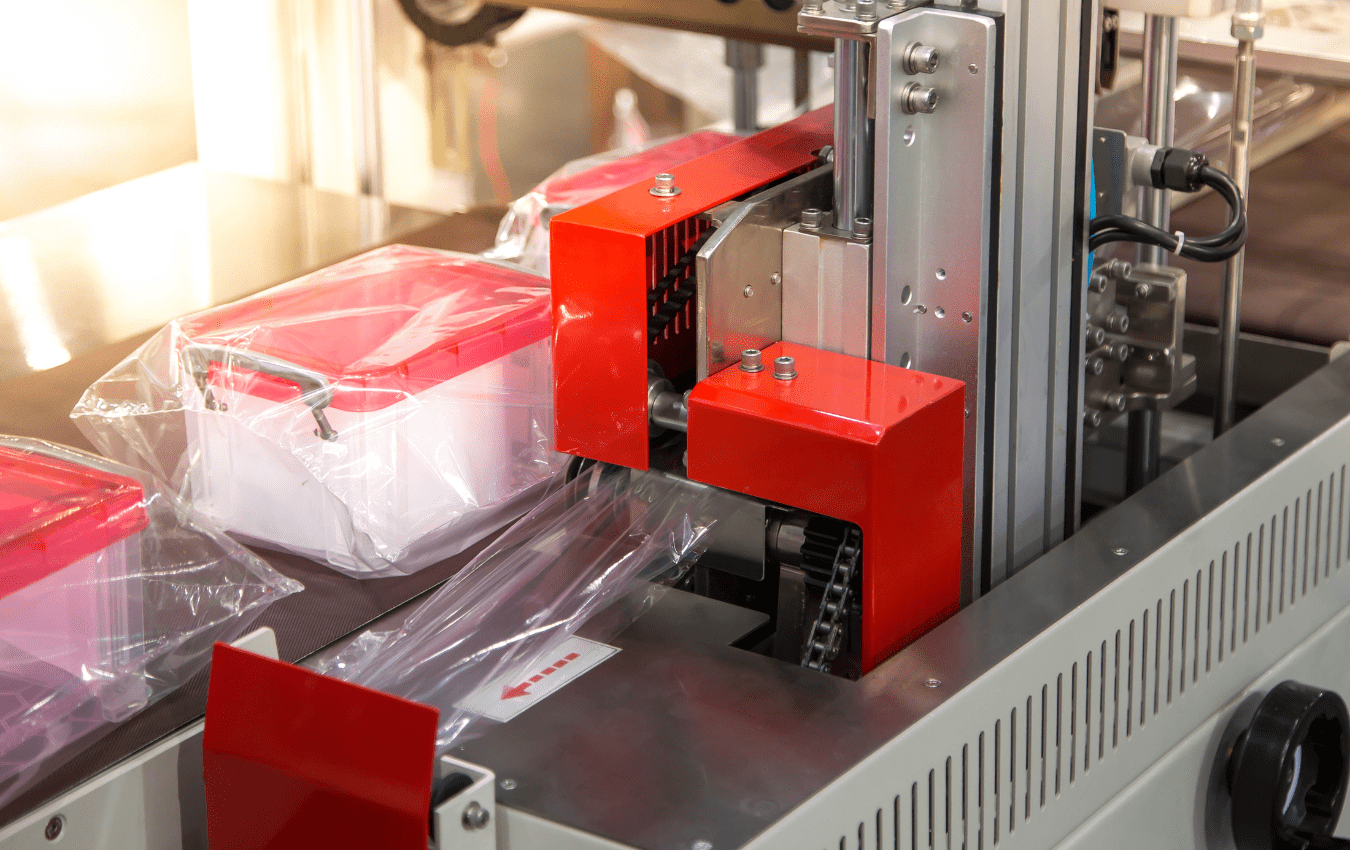

Roll stock flow wrap packaging, also known as horizontal form-fill-seal (HFFS) packaging, is a process that involves wrapping a continuous roll of flexible packaging material around a product or a group of products and then sealing it to create a sealed pouch or package. This packaging method is highly efficient and can accommodate a wide range of product sizes and shapes.

The process of roll stock flow wrap packaging typically involves the following steps:

- Material Unwinding: A roll of flexible packaging material (often made of materials like plastic films or laminates) is mounted on a machine. This roll contains pre-printed or clear film, depending on branding and product visibility requirements.

- Product Feeding: The products to be packaged are fed into the machine’s conveyor system. These products can be singular items, such as candy bars, or multiple items bundled together, such as a pack of cookies.

- Film Forming: The packaging machine forms the flexible film into a tubular shape around the product or product group. The film is wrapped tightly around the product(s), ensuring a snug fit.

- Sealing and Cutting: The film is sealed along its length and width, creating individual pouches for each product or product group. Simultaneously, a cutting mechanism severs the pouches from the continuous roll.

- Product Discharge: The finished packages are discharged from the machine’s conveyor belt, ready for further handling, labeling, and distribution.

Advantages of Roll Stock Flow Wrap Packaging:

Roll stock flow wrap packaging offers several advantages that make it a popular choice for many businesses:

- Efficiency: This packaging method is highly automated, allowing for rapid production rates and reduced labor costs.

- Versatility: Roll stock flow wrap machines can handle a wide range of product sizes, shapes, and types. Whether you’re packaging individual items or multi-packs, this method can adapt.

- Product Protection: The tightly wrapped film provides a barrier against moisture, dust, and contaminants, ensuring the product’s freshness and integrity.

- Customization: Packaging materials can be customized with branding, labels, and graphics to enhance product visibility and appeal.

- Cost-Effective: Roll stock packaging materials are generally cost-effective, and the efficiency of the process helps reduce overall packaging costs.

- Reduced Material Waste: The form-fill-seal process minimizes excess packaging material, reducing waste and environmental impact.

Considerations for Implementing Roll Stock Flow Wrap Packaging:

Before implementing roll stock flow wrap packaging in your business, consider the following key factors:

- Product Type: Ensure that your products are suitable for this packaging method. Products with irregular shapes, sharp edges, or those that are extremely delicate may require special considerations.

- Machine Size and Speed: Choose a machine that matches your production requirements in terms of speed and capacity.

- Material Selection: Select appropriate packaging materials that align with your product’s shelf life, protection needs, and branding goals.

- Maintenance and Training: Regular maintenance and operator training are essential for optimal machine performance and product quality.

- Regulatory Compliance: Ensure that your packaging meets all relevant regulatory requirements for food safety, labeling, and environmental considerations.

- Cost Analysis: Evaluate the overall cost-effectiveness of roll stock flow wrap packaging for your specific products, considering the initial investment in machinery and ongoing operational costs.

Roll stock flow wrap packaging is a versatile and efficient packaging solution that can enhance your product’s presentation, shelf life, and cost-effectiveness. By understanding the process and considering the relevant factors, businesses can make informed decisions about adopting this packaging method to meet their specific needs.

If you are interested in roll stock flow wrap packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength of an FOL container depends

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width of the box and overlap

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Home » Roll Stock Flow Wrap Packaging Explained