Home » Primary Packaging: The First Line of Defense for Products

Primary Packaging: The First Line of Defense for Products

In the world of product manufacturing and retail, packaging plays a crucial role in protecting products, attracting consumers, and conveying brand messages. Among the various types of packaging, primary packaging holds a special place as it is the first and most direct form of packaging around a product. This blog post aims to explore the concept of primary packaging, its importance, and its various forms.

What is Primary Packaging?

Primary packaging is the material that first envelops the product and holds it. This type of packaging is in direct contact with the product itself and is often the last to be opened by the consumer before using the product. It serves several critical functions, from protecting the product to providing consumer information and aiding in marketing efforts.

The Role of Primary Packaging

- Protection: The most fundamental role of primary packaging is to protect the product from damage, contamination, and tampering. It ensures the product remains intact and safe for use from the production line until it reaches the consumer.

- Preservation: For many products, especially food items and pharmaceuticals, primary packaging plays a crucial role in preserving the quality and extending the shelf life of the product by providing barriers to moisture, light, and air.

- Information and Compliance: Primary packaging is a key medium for conveying necessary product information, instructions for use, ingredients or contents, and compliance with regulatory requirements.

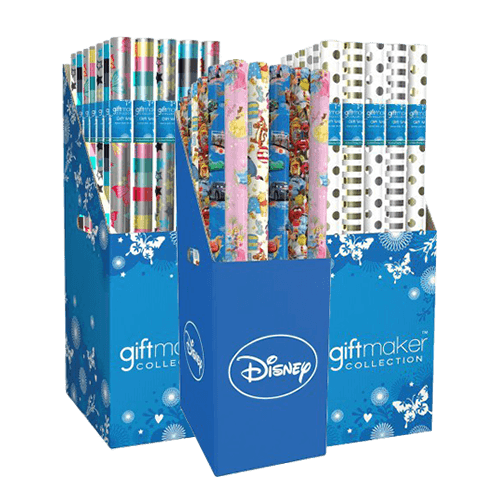

- Branding and Marketing: Often the first thing a consumer interacts with, primary packaging is an important branding tool. Its design, colors, and materials can significantly influence purchasing decisions and brand perception.

Types of Primary Packaging

Primary packaging can vary greatly depending on the product. Common types include:

- Bottles and Jars: Used for liquids and creams in the beverage, beauty, and pharmaceutical industries.

- Boxes and Cartons: Often used for electronics, cosmetics, and house hold items.

- Flexible Packaging: Such as pouches or bags, commonly used for snacks, grains, and frozen foods.

- Blister Packs: ideal for medical devices and electronics.

- Tubes: For semi-solid products like toothpaste or certain food items.

Materials Used in Primary Packaging

The choice of material for primary packaging is determined by the product’s needs and includes:

- Plastics: Versatile and widely used, suitable for a range of products.

- Glass: Preferred for its non-reactive nature, especially for food and pharmaceuticals.

- Metal: Often used for its durability and protective qualities.

- Paper and Cardboard: Commonly used for their recyclability and lightweight properties.

Design Considerations in Primary Packaging

Designing primary packaging requires a balance between functionality and aesthetics. It should be user-friendly, secure, and aligned with the brand’s identity. Additionally, sustainable design practices are increasingly important to reduce environmental impact.

Innovation and Trends in Primary Packaging

The primary packaging sector is seeing innovations like smart packaging, which includes the use of QR codes and RFID technology, and sustainable alternatives like biodegradable materials and minimalist designs.

If you are interested in primary packaging, then partner with Brown Packaging today to get started.

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Home » Primary Packaging: The First Line of Defense for Products

Full-Overlap (FOL) boxes are renowned for their structural integrity and robust design, making them a popular choice for packaging products that require extra protection during

In the world of ecommerce, packaging plays a crucial role in ensuring that products reach customers in perfect condition while also reflecting the brand’s image

Point of Purchase (POP) displays are a crucial element in the world of retail marketing. They play a significant role in catching the eye of