Home » POP Displays for Cross-Merchandising

POP Displays for Cross-Merchandising

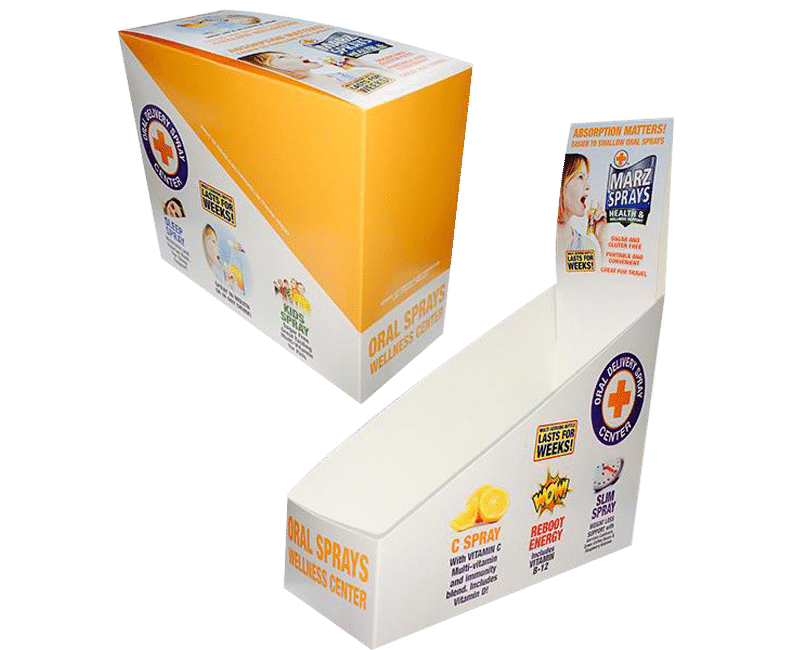

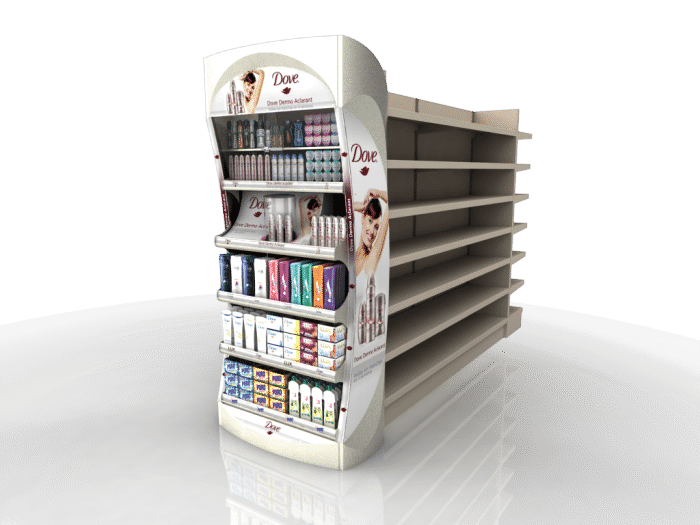

Cross-merchandising is one of the most effective ways to increase basket size in retail. By pairing complementary products in a single point-of-purchase (POP) display, brands can encourage impulse buys and highlight product synergies. Well-designed cross-merchandising displays must balance structural integrity with creative graphics to hold multiple SKUs securely while capturing shopper attention.

Why Cross-Merchandising Works

Shoppers often overlook product pairings when items are placed in separate aisles. POP displays solve this by bringing products together in a single, convenient location.

- Encourages impulse purchases.

- Educates consumers on product compatibility.

- Strengthens brand visibility and retailer relationships.

- Increases revenue per shopper visit.

Structural Considerations for Multi-SKU Displays

Cross-merchandising displays require careful engineering to hold different shapes and weights.

- Compartmentalized trays: Keep SKUs organized and accessible.

- Reinforced shelving: Prevent sagging under uneven product loads.

- Flexible layouts: Allow for multiple packaging sizes.

- Retail compliance: Dimensions must fit chain-specific guidelines.

Graphics That Highlight Product Pairings

Graphics play a key role in cross-merchandising by showing shoppers why products belong together.

- Use bold imagery to connect items visually.

- Highlight bundle savings or promotional pricing.

- Position brand messaging where both products share visibility.

- Ensure graphics remain clear even when product stock is low.

Examples of Cross-Merchandising POP Displays

- Snacks and beverages: Pairing chips with soda or beer.

- Health and beauty: Combining shampoo with conditioner or styling products.

- Electronics: Packaging batteries alongside small devices.

- Household goods: Cleaning products displayed with tools or accessories.

POP Display Solutions with Brown Packaging

Brown Packaging designs cross-merchandising POP displays that integrate structural strength with branding impact. Our solutions make it easy to showcase complementary products while meeting retailer standards. Contact us to explore custom display designs for your retail strategy.

References

Shop! Association. (2021). Best Practices for In-Store Marketing and POP Displays. Retrieved from https://www.shopassociation.org

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

ASTM International. (2022). ASTM D685: Standard Practice for Conditioning Paper and Paper Products for Testing.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall logistics expenses. Full Overlap (FOL)

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » POP Displays for Cross-Merchandising