Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

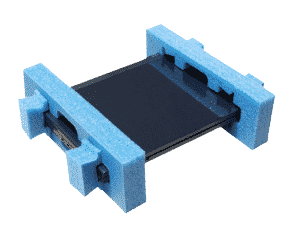

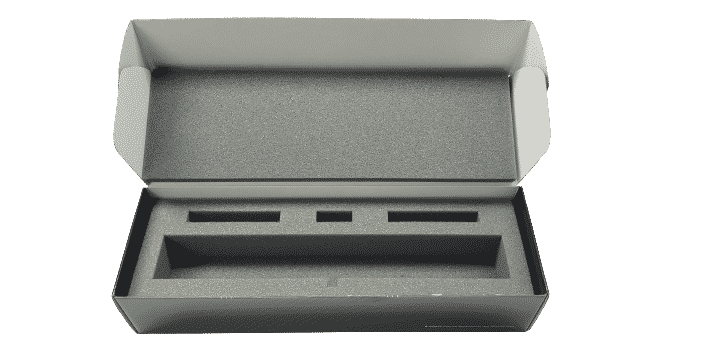

When it comes to protecting fragile or valuable items during shipping or storage, the choice of packaging material can make all the difference. Polyurethane foam is a versatile and highly effective material that has gained popularity in the world of packaging. In this comprehensive guide, we will explore what polyurethane foam is, its properties, benefits, and various applications in packaging. Introduction to Polyurethane Foam Polyurethane foam is a versatile polymer material that is widely used in various industries, including construction, automotive, and of course, packaging. It is created through the reaction of polyols and isocyanates, resulting in a foam with a wide range of properties, making it suitable for diverse applications. In packaging, polyurethane foam is valued for its ability to provide cushioning and protection to fragile and sensitive items, effectively preventing damage during transit. Properties of Polyurethane Foam Physical Properties Flexibility: Polyurethane foam is highly flexible, allowing it to conform to the shape of the object it is protecting, ensuring a snug and secure fit. Density: It is available in various densities, ranging from low-density foam for cushioning to high-density foam for structural support. Compression Strength: Polyurethane foam can withstand a wide range of compressive forces, making it ideal for items of varying weights and sizes. Thermal Insulation: It offers some degree of thermal insulation, which can be crucial for products sensitive to temperature changes. Chemical Properties Chemical Resistance: Polyurethane foam exhibits resistance to many chemicals, which can protect items from exposure to corrosive substances. Moisture Resistance: It is inherently resistant to moisture, helping to prevent damage due to water or humidity exposure. Benefits of Using Polyurethane Foam in Packaging Shock Absorption and Impact Resistance: One of the primary benefits of polyurethane foam is its exceptional shock absorption and impact resistance. It effectively absorbs and dissipates energy from impacts, reducing the risk of damage to packaged items. Customization and Versatility: Polyurethane foam can be easily cut and shaped to fit the specific dimensions of the item being packaged. This versatility allows for precise and tailored protection. Moisture Resistance: Its inherent resistance to moisture makes polyurethane foam an excellent choice for products that are sensitive to humidity or may encounter wet conditions during shipping. Lightweight and Space Efficiency: Polyurethane foam is lightweight, helping to minimize shipping costs. Its ability to compress and expand as needed also makes it space-efficient. Applications of Polyurethane Foam in Packaging Electronics Packaging: Polyurethane foam is commonly used to protect delicate electronics such as laptops, smartphones, and components during transit. Medical Device Packaging: Medical devices, which often have sensitive components, benefit from polyurethane foam’s protective properties. Automotive Parts Packaging: Automotive parts, from small components to large body panels, are safeguarded during shipping with polyurethane foam. Fragile Goods Packaging: Fragile items like glassware, ceramics, and artworks are frequently packed with polyurethane foam to prevent breakage. Choosing the Right Polyurethane Foam When selecting polyurethane foam for packaging, consider the following factors: Density: Choose the foam density based on the weight and fragility of the item. Heavier or delicate items may require higher-density foam for better protection. Hardness: The foam’s hardness or firmness should match the level of cushioning needed. Softer foams offer more cushioning, while firmer foams provide better support. Size and Shape: Customize the foam’s size and shape to ensure a snug fit around the item. Manufacturing and Customization Polyurethane foam can be tailored to meet specific packaging needs. Manufacturers can create custom foam inserts, shapes, and sizes to perfectly fit the item being packaged. If you are interested in polyurethane foam, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

One of the fundamental decisions that buyers face when it comes to packaging is whether to prioritize quality or quantity. This choice can significantly impact your brand image, customer satisfaction, and overall packaging costs. In this detailed blog, we will explore the factors that influence the decision between quality and quantity in packaging, helping you make informed choices that align with your business goals. Quality Packaging: The Value of Excellence Quality packaging is all about creating a premium and memorable experience for your customers. Here’s why it matters: Brand Perception: High-quality packaging communicates that your brand cares about every detail. It reflects a commitment to excellence, which can elevate your brand image. Customer Experience: Quality packaging enhances the unboxing experience. It creates anticipation and excitement, leaving a lasting impression on customers. Protection: Premium materials and construction offer better protection for your products, reducing the risk of damage during transit. Sustainability: Quality packaging often incorporates eco-friendly materials and design, aligning with sustainability goals and customer preferences. Reusability: Durable packaging can be reused by customers, extending its lifespan and providing ongoing brand exposure. Quantity Packaging: Balancing Cost and Efficiency Quantity packaging prioritizes cost-effectiveness and efficiency. Here’s why it’s a practical choice: Cost Savings: Quantity packaging is usually more cost-effective due to lower material and production costs. It allows you to allocate resources to other aspects of your business. High-Volume Demands: Businesses with high shipping volumes may prioritize quantity packaging to meet demand efficiently. Standardization: Standard packaging sizes and designs simplify logistics and reduce lead times. Minimalism: Quantity packaging often adopts a minimalist approach, which can be appealing in industries where simplicity is valued. Sustainability: Streamlined packaging can reduce waste, supporting sustainability initiatives. Making the Decision To make an informed choice between quality and quantity packaging, consider the following factors: Product Type: The nature of your product plays a crucial role. Fragile or luxury items may benefit from quality packaging, while standard or non-fragile products may work well with quantity packaging. Target Audience: Understand your target audience’s preferences. High-end customers may expect premium packaging, while cost-conscious shoppers may prioritize quantity. Brand Identity: Consider your brand identity and values. If your brand is associated with luxury, quality packaging may be essential. For a budget-friendly or minimalist brand, quantity packaging may be more suitable. Budget Constraints: Assess your budget and packaging costs. Quality packaging may have a higher upfront cost, but it can yield long-term benefits. Quantity packaging can help you manage costs efficiently. Environmental Impact: Sustainability is a growing concern. Evaluate the environmental impact of your packaging choices and opt for eco-friendly options when possible. Logistics and Storage: Consider storage space and logistics. Quantity packaging may require more storage space, while quality packaging may reduce returns due to damage. Finding a Balance In some cases, finding a balance between quality and quantity packaging is the ideal solution. For example: Tiered Packaging: Offer premium packaging options for select products or customers, allowing you to cater to different preferences. Seasonal Variations: Adjust your packaging strategy seasonally or during promotions to strike the right balance between quality and quantity. Customization: Explore customization options that allow you to add branding elements to quantity packaging, enhancing the overall experience. Conclusion The choice between quality and quantity packaging is not always straightforward. It depends on various factors, including your product type, target audience, brand identity, budget, and environmental considerations. Ultimately, finding the right balance between the two approaches can help you meet customer expectations, manage costs effectively, and align with your brand’s values. By making informed choices in packaging, you can enhance your brand’s image, customer satisfaction, and overall success. If you are interested in packaging options, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to food products, packaging plays a crucial role in maintaining freshness, preventing contamination, and ensuring the safety of what we consume. Food-grade packaging materials are specially designed and regulated to meet the unique demands of the food industry. In this blog, we will dive into the world of food-grade packaging, exploring its significance, characteristics, and compliance with food safety regulations. The Importance of Food-Grade Packaging Safety First: Food-grade packaging materials are chosen to prevent any interaction or contamination between the packaging and the food it contains. This ensures that the product remains safe for consumption. Preservation of Freshness: Food-grade packaging helps preserve the freshness, flavor, and quality of food products, extending their shelf life and reducing food waste. Consumer Confidence: The use of food-grade packaging reassures consumers that the product has been handled and stored with their safety in mind, enhancing trust in the brand. Regulatory Compliance: Compliance with food safety regulations is a legal requirement for packaging used in the food industry. Using food-grade materials ensures adherence to these regulations. Characteristics of Food-Grade Packaging Food-grade packaging materials possess specific characteristics that make them suitable for use in the food industry: Inertness: Food-grade materials are inert, meaning they do not react with or alter the composition of the food they come into contact with. This prevents any chemical migration that could compromise food safety. Barrier Properties: Food-grade packaging often has excellent barrier properties to protect the contents from external factors such as moisture, oxygen, and light, which can lead to spoilage and degradation. Resistance to Contaminants: These materials are resistant to contaminants, including microorganisms, mold, and pests, to maintain the purity of the packaged food. High-Quality Printing: Food-grade packaging allows for high-quality printing of labels and graphics, which is essential for conveying information to consumers and enhancing product appeal. Tamper-Evidence: Many food-grade packages incorporate tamper-evident features to provide consumers with assurance that the product has not been tampered with during storage or transportation. Compliance with Food Safety Regulations Food-grade packaging must adhere to stringent food safety regulations and standards established by governmental agencies and industry organizations. These regulations vary by region but generally cover aspects such as: Materials: The packaging materials must be approved for contact with food and should not contain harmful substances. Hygiene: Packaging facilities must adhere to strict hygiene standards to prevent contamination during the packaging process. Labeling: Packaging must include accurate and comprehensive labeling, including ingredients, nutrition information, allergen warnings, and expiration dates. Common Food-Grade Packaging Materials Several materials are commonly used for food-grade packaging, including: Plastics: Food-grade plastics such as polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are widely used for their durability and barrier properties. Glass: Glass containers are inert and do not interact with food, making them a classic choice for preserving flavor and quality. Metals: Aluminum and tinplate cans are often used for canned goods due to their resistance to external factors. Paperboard: Food-grade paperboard is used for various types of packaging, including cartons and boxes. Corrugated: Corrugated packaging, made from corrugated cardboard, is another food-grade material commonly used for shipping boxes and retail packaging, known for its sturdiness and recyclability. Special coating may be required if in direct contact with food. Conclusion Food-grade packaging is an essential component of the food industry, ensuring that the products we consume remain safe, fresh, and of high quality. By selecting packaging materials that comply with food safety regulations and possess the necessary characteristics, food producers and manufacturers can maintain consumer trust, enhance product appeal, and contribute to the overall safety and enjoyment of food products. If you are interested in food grade packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In October 2024, California made a groundbreaking move by banning “sell by” dates on food products. This legislation aims to reduce consumer confusion, minimize food waste, and introduce standardized freshness terms across the state. Effective July 1, 2026, this new law has far-reaching implications for packaging design, production, and compliance. For packaging buyers, it is crucial to understand these changes and their impact on packaging strategies to make informed decisions. The Problem with “Sell By” Dates Historically, “sell by” dates have been used as a tool for inventory management, intended for retailers rather than consumers. However, many consumers misinterpret these dates as indicators of food safety, leading to the premature disposal of perfectly edible food. According to studies, this confusion contributes to approximately 70,000 tons of food waste annually in California alone. What Does the New Law Require? The law eliminates “sell by” dates and replaces them with clear, standardized terms that better communicate product freshness to consumers. These terms are expected to include: “Best If Used By”: Indicates the period for optimal quality or flavor. “Use By”: Reflects the last date recommended for the product’s peak quality, often tied to food safety for perishable items. By standardizing labels, California aims to enhance consumer understanding, reduce food waste, and align with global best practices in food labeling. How This Affects Packaging Buyers Packaging buyers must prepare for the operational and design changes required to comply with this legislation. Here’s how the new rules impact the packaging industry and what buyers need to consider: Redesigning Labels The shift to standardized terms requires updates to all food product packaging sold in California. Key Considerations: Ensure compliance with the mandated labeling terms. Collaborate with graphic designers to revise labels while maintaining brand identity. Confirm that new labels are clear and legible for consumers. Adjusting Printing Processes Buyers may need to adjust printing specifications or partner with new suppliers to accommodate the updated labeling requirements. Actionable Steps: Evaluate whether current printing equipment and processes can support the new labeling formats. Plan ahead to avoid delays or increased costs during the transition. Managing Compliance Across States If your business operates in multiple states, consider how to address varying labeling laws. Options for Buyers: Implement California-compliant labels nationwide to streamline production. Use region-specific packaging if distinct compliance is necessary. Sustainability Opportunities The new law aligns with sustainability goals by reducing food waste, providing an opportunity for packaging buyers to align their strategies. How Buyers Can Respond: Highlight eco-friendly materials in packaging to reinforce your brand’s commitment to sustainability. Include consumer education elements, such as QR codes, that provide additional information on food storage and expiration. Cost Implications While the changes may involve upfront costs, compliance can prevent fines and align your products with consumer preferences. Potential Costs: Redesigning and reprinting packaging. Updating inventory and supply chain processes. Training staff on new compliance requirements. Benefits of the New Law for Packaging Buyers While adapting to this legislation requires investment, it also presents several opportunities: Building Consumer Trust Clear and standardized labels improve transparency, helping consumers make informed decisions and fostering trust in your brand. Reducing Waste in Supply Chains With less food discarded due to misunderstood labels, businesses can optimize inventory and reduce losses, saving costs in the long term. Staying Ahead of National Trends California often leads the way in regulatory changes that later influence national policies. Preparing for these changes now could position your business ahead of future federal regulations. Enhancing Brand Reputation By adopting clear, consumer-focused labeling, you align with growing consumer demand for accountability and clarity in packaging. Steps to Prepare for the Labeling Transition To ensure a smooth transition, packaging buyers should take the following steps: Conduct an Audit of Current Labels: Review all products sold in California to identify labels that require updates. Collaborate with Suppliers: Work closely with suppliers to revise labels and ensure timely production. Plan and Budget for the Transition: Allocate resources for redesign, printing, and potential supply chain adjustments. Educate Internal Teams: Train staff on the new labeling requirements and their implications for production and sales. Communicate with Retailers and Distributors: Ensure that partners in the supply chain understand and comply with the new standards. Conclusion California’s new food date labeling law is a significant step toward reducing food waste and improving consumer understanding. For packaging buyers, this change presents both challenges and opportunities. By preparing early and aligning your packaging strategies with the new standards, you can ensure compliance, enhance consumer trust, and support sustainability goals. With thoughtful planning, the transition can become a competitive advantage in the ever-evolving packaging industry. If you are interested in making your food packaging compliant, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Food Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

The weight a corrugated box can hold depends on factors such as box construction, material grade, flute size, and box dimensions. Corrugated boxes are designed to protect and hold items during storage and shipping efficiently. A standard single-wall corrugated box can hold between 20 to 120 pounds, while double-wall constructions can support significantly higher weights ranging from 80 to 180 pounds. Understanding Corrugated Box Strength Corrugated box strength is determined by multiple factors, including construction, material grade, and flute size. Understanding these variables ensures the right box is chosen for the job. Box Construction Corrugated boxes are available in three main constructions: Single-Wall Boxes: Suitable for lighter items with weight capacities ranging from 20 to 120 lbs, depending on the material strength. Double-Wall Boxes: Designed for heavier or fragile items, supporting weights from 80 to 180 lbs. Triple-Wall Boxes: Used for exceptionally heavy items, such as industrial equipment, capable of holding hundreds of pounds. Material Strength: Bursting Test and Edge Crush Test (ECT) Two key measurements determine corrugated box strength: Bursting Strength Test: Measures the force required to rupture the surface of corrugated board. Edge Crush Test (ECT): Measures stacking strength and indicates how much weight a box can withstand before collapsing. The following tables summarize the equivalencies for single-wall and double-wall corrugated boxes: Single-Wall Corrugated Boxes Bursting Test Minimum Edge Crush Test (ECT) Maximum Suggested Loading Limit Per Carton 125# 23 ECT 20 lbs. 150# 26 ECT 35 lbs. 175# 29 ECT 50 lbs. 200# 32 ECT 65 lbs. 275# 44 ECT 95 lbs. 350# 55 ECT 120 lbs. Double-Wall Corrugated Boxes Bursting Test Minimum Edge Crush Test (ECT) Maximum Suggested Loading Limit Per Carton 200# 42 ECT 80 lbs. 275# 48 ECT 100 lbs. 350# 51 ECT 120 lbs. 400# 61 ECT 140 lbs. 500# 71 ECT 160 lbs. 600# 82 ECT 180 lbs. These standardized tests ensure the durability and reliability of corrugated boxes, helping buyers choose boxes that meet their weight requirements. The Role of Flute Size Corrugated boxes use fluted sheets to provide strength and cushioning. Larger flutes (like A or B flutes) offer better compression resistance and are ideal for heavier items, while smaller flutes (like E or F flutes) provide a smoother surface for printing and are better for lightweight items. The Importance of Box Dimensions Box size directly affects weight capacity and strength. Larger boxes have a wider surface area, which can distribute weight evenly but may require stronger materials to prevent collapse. Choosing the appropriate box size can optimize load support and minimize material waste. How to Choose the Right Box To ensure optimal performance, consider the following when selecting a corrugated box: Determine the Weight of the ContentsUse the tables above to match the weight of your products with the appropriate box strength. Evaluate the Box Construction Single-wall for lightweight items. Double-wall for medium to heavy items. Triple-wall for extremely heavy or industrial goods. Consult with SuppliersCollaborate with packaging experts to select boxes with the proper ECT or bursting strength for your application. Optimize for SustainabilityChoose boxes made from recycled or sustainable materials without compromising strength. Conclusion The weight a corrugated box can hold depends on its construction, material grade, and strength ratings (ECT and bursting test). Single-wall boxes can hold up to 120 lbs, while double-wall boxes can support weights up to 180 lbs, as shown in the tables above. By understanding these key metrics and factors, packaging buyers can confidently choose the right boxes for their needs, ensuring products are protected during shipping and storage. Partner with Brown Packaging today to find corrugated boxes designed to meet your weight, size, and durability requirements. Whether you’re shipping lightweight goods or industrial equipment, we’ve got the solution for you! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts