Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

In the realm of packaging, the safe transport and protection of delicate and fragile items are paramount. Foam materials serve as the frontline defense in ensuring that products remain intact throughout the rigors of transportation and handling. This comprehensive guide delves into the pivotal role of shock absorption properties in foam packaging, their profound impact on product protection, and the key considerations when selecting the ideal foam for your packaging needs. Understanding Shock Absorption Properties Before delving into the importance of shock absorption properties, it’s vital to grasp their essence. Shock absorption properties in foam packaging are primarily concerned with the foam’s ability to dissipate and absorb energy when subjected to sudden impacts or shocks. These properties encompass two key aspects: Compression Deflection (Firmness): This metric gauges the force required to compress a foam material by a specified percentage of its original thickness. It dictates the foam’s firmness and its resistance to deformation under load. Compression Set: Compression set assesses the foam’s capacity to regain its initial shape after being compressed. It quantifies the foam’s ability to rebound to its original form once the external pressure is removed. The Role of Shock Absorption Properties Safeguarding Against Impact and Shock The primary role of foam in packaging is to act as a protective barrier, shielding products from the perils of impact and shock during transit and handling. The compression deflection of foam directly influences its aptitude for absorbing and dissipating the energy generated by these impacts. Foam with well-suited compression deflection properties significantly mitigates the risk of damage to packaged goods, ensuring their pristine condition upon arrival. Preserving Product Integrity For fragile and sensitive products, maintaining their structural integrity is of paramount importance. A foam with appropriate compression set properties guarantees that, even after experiencing compression during packaging or transit, the foam will faithfully revert to its original shape. This characteristic holds particular significance for products with intricate shapes or those that necessitate secure placement within the packaging. Uniform Distribution of Forces In certain instances, packaged items may endure prolonged periods of compression, whether due to stacking in storage or during transit. The shock absorption properties of foam become crucial in such scenarios. Foam materials that boast well-matched compression deflection and compression set characteristics serve to evenly distribute the load, averting uneven pressure points that could culminate in deformation or harm to the packaged items. Customization and Versatility Packaged items come in diverse forms and dimensions, necessitating adaptable packaging solutions. By selecting foam with the appropriate shock absorption properties, packaging designers can ensure that the foam seamlessly conforms to the unique contours and fragility of each item. This tailored approach to protection is a hallmark of effective foam packaging. Choosing the Optimal Foam Material The process of selecting the right foam material with fitting shock absorption properties involves a comprehensive evaluation of your packaging prerequisites and the fragility of the products in question. Key considerations encompass: Product Weight: Bulkier items may necessitate foam with a higher compression deflection to withstand the load without undergoing deformation. Product Fragility: Items susceptible to breakage or damage benefit significantly from foam with suitable compression deflection and compression set properties, effectively absorbing and recuperating from shocks. Packaging Configuration: The design and structure of your packaging play a pivotal role in determining the foam’s shock absorption requisites. Tailored foam inserts can be instrumental in optimizing protection. Environmental Conditions: Contemplate the environmental conditions to which the packaged items will be exposed. Some foam materials are better suited for extreme temperatures or conditions involving moisture. Budgetary Considerations: Strike a balance between your packaging needs and budget constraints. Different foam materials may come at varying costs, so select one that aligns with your requirements without exceeding your budget. If you are interested in foam packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Foam Folding Carton Packaging Printing Protection Retail Rigid Box Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In a world where a wide range of products require special handling to maintain their quality, insulated packaging has emerged as a crucial solution for protecting temperature-sensitive items from both UV radiation and temperature fluctuations. Whether it’s perishable food items, pharmaceuticals, or sensitive electronics, maintaining the right temperature during storage and transportation is paramount. In this blog, we’ll explore insulated packaging, its functions, features, benefits, and applications in safeguarding temperature-sensitive products. Understanding Insulated Packaging Insulated packaging, also known as thermal packaging or temperature-controlled packaging, is designed to create a controlled environment within the package. It acts as a protective shield against external factors, including temperature fluctuations and UV radiation, to maintain the integrity and quality of the enclosed products. Functions and Features Temperature Stability: The primary function of insulated packaging is to maintain a stable temperature environment inside the package. It accomplishes this through the use of insulating materials that resist heat transfer, keeping the contents at the desired temperature. UV Radiation Blockage: Insulated packaging often includes materials that provide protection against UV radiation. These materials block harmful UV rays, preventing them from reaching and potentially damaging the enclosed products. Insulation Materials: Insulated packaging employs a variety of insulation materials such as foam, reflective films, and vacuum insulation panels. These materials help regulate temperature and prevent heat or cold from penetrating the package. Temperature Monitoring: Some insulated packaging solutions come equipped with temperature monitoring devices like data loggers or indicators. These devices allow for real-time monitoring of the internal temperature, ensuring that it remains within the desired range. Benefits of Insulated Packaging Product Quality Preservation: Insulated packaging ensures that temperature-sensitive products, including food, medications, and electronics, maintain their quality and efficacy throughout their journey from manufacturer to end-user. Extended Shelf Life: Products with shorter shelf lives can benefit from insulated packaging. It helps extend the time during which these products remain safe and viable for consumption or use. Reduced Waste: By preventing spoilage and product degradation, insulated packaging reduces the amount of wasted products, saving both resources and money. Enhanced Brand Reputation: Companies that prioritize the protection of temperature-sensitive products through insulated packaging can build trust with consumers and enhance their brand reputation. Applications of Insulated Packaging Insulated packaging finds application in various industries: Food and Beverage: Insulated packaging is widely used for shipping perishable food items, including fresh produce, dairy products, and frozen goods. It ensures that these products reach consumers in optimal condition. Pharmaceuticals: Pharmaceutical companies rely on insulated packaging to transport temperature-sensitive medications and vaccines, ensuring their safety and efficacy. Electronics: Sensitive electronic components and devices, such as microchips and batteries, benefit from insulated packaging to prevent damage caused by temperature fluctuations. Online Retail: E-commerce companies often use insulated packaging for shipping products that require temperature control, such as meal kits and specialty cosmetics. If you are interested in insulated packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Cold Chain Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

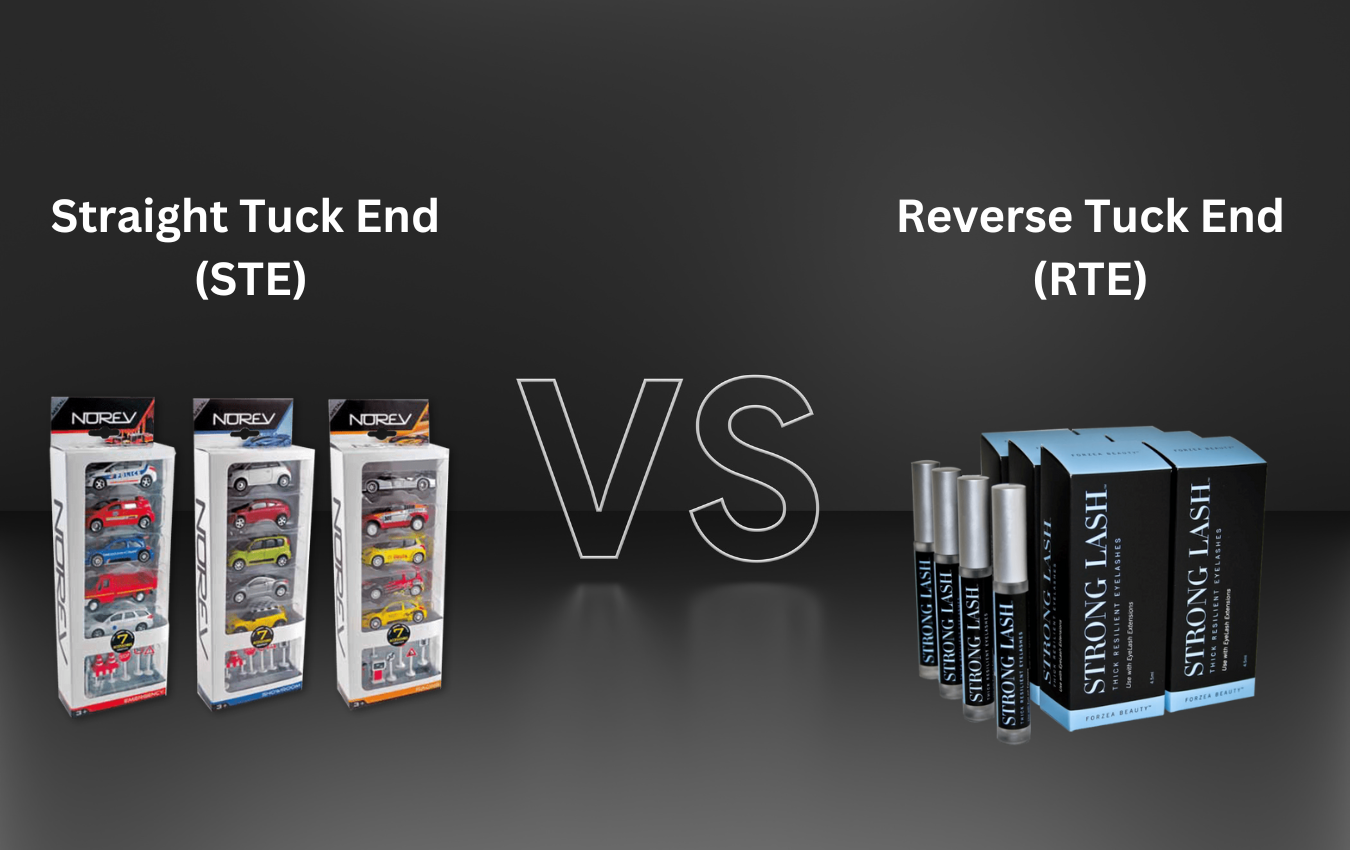

Folding cartons are a staple in the packaging industry, known for their versatility and functionality. Among the various styles available, two popular choices are the straight tuck end (STE) and reverse tuck end (RTE) cartons. Each style offers unique features and advantages that cater to different packaging needs. In this blog, we will explore the functions, features, design considerations, benefits, and applications of both straight tuck end and reverse tuck end cartons to help you make an informed decision. Straight Tuck End (STE) Cartons Functions and Features: Opening and Closing Mechanism: Straight tuck end cartons feature tuck flaps on the same side at the top and bottom of the box. These flaps can be easily tucked into the carton for closure, providing a secure seal. Design Versatility: STE cartons offer ample design flexibility, with options for custom die-cut windows, embossing, foil stamping, and various printing techniques. This makes them ideal for branding and product visibility. Ease of Assembly: These cartons are user-friendly, as they can be quickly assembled by hand, reducing labor costs in packaging lines. Benefits: Secure Closure: The straight tuck design ensures that the contents remain securely enclosed within the carton, reducing the risk of tampering or damage during transit. Aesthetic Appeal: STE cartons can be designed with a premium look and feel, making them suitable for high-end products like cosmetics, pharmaceuticals, and luxury goods. Cost-Effective: They are often more cost-effective than other carton styles due to their straightforward design and ease of production. Inserts: STE cartons can be made with inserts that provide customizable support and protection, ideal for securing fragile items like electronics or glass during transit. They also enhance product presentation by being designed to fit the exact shape of the product, significantly improving the unboxing experience and making the carton especially appealing for gift items and luxury products where first impressions are key. Window Cutouts: Window cutouts in STE cartons offer product visibility, allowing consumers to view the product inside without opening the packaging, which is particularly advantageous for items where visual appeal influences purchasing decisions, such as food, toys, or beauty products. These cutouts not only enhance shelf appeal by showcasing the product and differentiating it on retail shelves but also provide customization options in terms of shape and size, aligning closely with marketing and branding strategies to create a distinctive visual identity. Applications: Straight tuck end cartons find wide application across various industries, including: Cosmetics and beauty products Pharmaceuticals and healthcare Electronics accessories Food and confectionery Apparel and clothing Reverse Tuck End (RTE) Cartons Functions and Features: Opposite Tuck Closure: Reverse tuck end cartons have tuck flaps on opposite sides of the carton. The top flap tucks into the rear panel, while the bottom flap tucks into the front panel. Product Accessibility: RTE cartons offer easy access to the product as both the top and bottom can be opened separately. This feature is particularly convenient for consumers. Design Space: These cartons provide ample space for product information, branding, and graphics on both the front and rear panels. Benefits: Convenient Access: The reverse tuck design allows consumers to access the product without fully opening the carton, making it user-friendly. Efficient Storage: RTE cartons stack efficiently, saving space during storage and transportation. Versatile Applications: They are versatile and suitable for various product sizes and industries, including electronics, hardware, pharmaceuticals, and consumer goods. Applications: Reverse tuck end cartons are commonly used in the following industries: Electronics and gadgets Hardware and tools Pharmaceuticals and vitamins Consumer goods and retail Office and stationery products Choosing the Right Carton Style: What to Include in Your Decision When deciding between straight tuck end and reverse tuck end cartons, consider the following factors: Product Type: Think about the nature of your product. If it requires easy access for consumers, reverse tuck end cartons may be more suitable. For products requiring a premium presentation, straight tuck end cartons may be preferable. Branding and Design: Assess your branding and design requirements. If you need a larger canvas for graphics and information, reverse tuck end cartons offer more space. However, if you want an elegant and secure packaging solution, straight tuck end cartons might be the better choice. Window and Insert: Consumer Experience: Consider the end-user experience. If convenience and ease of opening are paramount, reverse tuck end cartons are designed with consumers in mind. If you are interested in folding cartons and specific styles such as STE, RTE, auto bottom and more, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Folding Cartons Facebook Twitter LinkedIn Pinterest Relevant Posts

Yes, a corrugated box is an excellent choice for shipping due to its strong, durable nature and its ability to protect contents from damage during transit. Its structural integrity, coupled with its lightweight design, makes it ideal for a wide range of shipping needs, from delicate items to heavy goods. Strength and Durability The key to the corrugated box’s suitability for shipping lies in its unique construction. Composed of a fluted corrugated sheet sandwiched between two linerboards, this design creates a sturdy, yet cushioned, environment for items being shipped. The corrugation provides resistance against impacts, vibrations, and compression, significantly reducing the risk of damage. This structural strength is scalable; by adjusting the thickness of the board and the size of the flutes, corrugated boxes can be customized to handle various weight capacities and protection levels. Versatility Corrugated boxes offer unparalleled versatility. They can be customized in size, shape, and strength to suit specific shipping needs, whether for small, fragile items or large, bulky products. This customization extends to the printing and branding of the boxes, enabling businesses to use their packaging as a marketing tool. Moreover, additional features like handles, die-cut inserts, or reinforced corners can be added to enhance functionality and protection. Sustainability In an era where environmental concerns are increasingly important, corrugated boxes stand out for their eco-friendliness. Made from renewable resources, primarily recycled paper, corrugated boxes are recyclable and biodegradable. Their production and recycling processes are energy efficient and contribute to a reduction in carbon footprint, making corrugated boxes a responsible choice for businesses committed to sustainability. Protective Features Corrugated boxes can also be equipped with various protective features to enhance their shipping capabilities. These include water-resistant coatings or liners, which protect against moisture and humidity, and barrier coatings that guard against oil, grease, or other contaminants. For items requiring temperature control, insulated corrugated boxes are available to maintain a stable environment during transit. Ease of Use The simplicity and ease of use of corrugated boxes are significant benefits. They can be quickly assembled, filled, sealed, and labeled, making the packing process efficient and straightforward. At the destination, they are easy to open and, if undamaged, can be reused or recycled, contributing to waste reduction. Conclusion Corrugated boxes are indeed an excellent choice for shipping, offering a combination of strength, durability, cost efficiency, and environmental sustainability. Their adaptability to various shipping requirements, coupled with protective and customizable features, makes them a reliable packaging solution for businesses and individuals worldwide. Whether you’re shipping locally or internationally, corrugated boxes ensure that your products arrive safely, securely, and in style. If you are interested in corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Saving on the purchase of corrugated boxes involves strategic planning and smart sourcing to ensure you get the best value without compromising on quality. By exploring bulk purchasing, negotiating with suppliers, opting for standard sizes, and considering lightly used or recycled boxes, businesses can significantly reduce their packaging costs. Bulk Purchasing One of the most straightforward ways to save on corrugated boxes is by buying in bulk. Manufacturers often offer substantial discounts for large orders due to the lower logistics and handling costs involved. Bulk purchasing not only reduces the per-unit cost but also minimizes the frequency of reordering, saving additional time and shipping expenses. It’s essential, however, to have adequate storage space and to ensure that the bulk quantity aligns with your usage to avoid unnecessary stockpiling. Supplier Negotiation and Comparison Establishing a good relationship with suppliers can open the door to discounts, especially if your business is a repeat customer. Don’t hesitate to negotiate prices or ask for special deals. Additionally, regularly comparing prices from different suppliers can uncover more competitive rates or better terms. Keep in mind that the cheapest option is not always the best choice if it compromises box quality, which can lead to product damage and higher costs in the long run. Recycled and Lightly Used Boxes For businesses committed to sustainability and looking to save on costs, recycled or lightly used corrugated boxes are an excellent option. Many suppliers offer high-quality recycled boxes at a fraction of the cost of new ones. These boxes can be just as durable and reliable as new ones, especially if they have only been used once or twice. Moreover, opting for recycled boxes reduces your environmental footprint and supports circular economy practices. Efficient Design and Material Use Work with your box supplier to design packaging that uses material efficiently. Reducing material waste not only lowers costs but also benefits the environment. Consider lighter-weight corrugated options that still provide adequate protection for your products. Innovations in corrugated box design can result in the use of less material without sacrificing box integrity or performance. Inventory Management Effective inventory management can also lead to savings. By carefully monitoring your box usage and inventory levels, you can avoid rush orders, which often come with premium shipping costs. Predictable ordering patterns can also strengthen your negotiating position with suppliers, potentially leading to better prices or terms. Conclusion Saving on corrugated boxes requires a multi-faceted approach that includes smart purchasing strategies, supplier negotiations, and a commitment to efficient design and sustainability. By adopting these practices, businesses can significantly reduce their packaging expenses while still ensuring their products are well-protected. Remember, the goal is to find a balance between cost savings and maintaining the quality and integrity of your packaging to support your brand’s reputation and customer satisfaction. If you are interested in corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts