Home » Packaging Strategies for Generation X

Packaging Strategies for Generation X

Generation X, typically defined as those born between 1965 and 1980, holds significant purchasing power and influence in today’s market. Often characterized as pragmatic and value-oriented, this demographic has distinct preferences when it comes to packaging. Brands looking to appeal to Generation X need to understand their unique values and priorities. This blog post explores effective packaging strategies that resonate with Generation X, offering insights for brands to effectively engage with this demographic.

Understanding Generation X Values

To design packaging that appeals to Generation X, it’s important to grasp their core values:

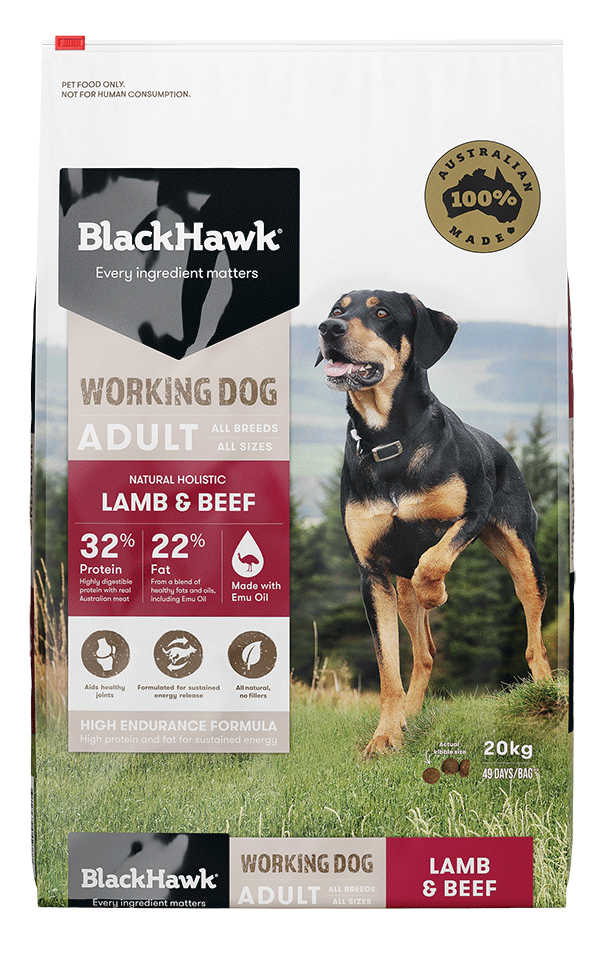

- Practicality and Functionality: Gen Xers value practicality and straightforward functionality in products and packaging.

- Quality and Durability: This generation tends to prioritize quality and durability over flashy or trendy designs.

- Brand Loyalty: Once loyal to a brand, Gen X consumers are likely to remain loyal, provided the quality and value remain consistent.

- Environmental Awareness: While not as vocal as millennials or Gen Z, Gen Xers are environmentally conscious and appreciate sustainable practices.

Designing for Practicality and Ease of Use

Functionality is key for packaging aimed at Generation X.

- User-Friendly Design: Ensure that packaging is easy to open, use, and store. Consider the ergonomics of packaging, especially for products used frequently.

- Clear Instructions: Include straightforward and easy-to-read instructions or product information.

Emphasizing Quality and Durability

Generation X tends to view purchases as long-term investments.

- Durable Materials: Use high-quality materials that convey the durability and longevity of the product.

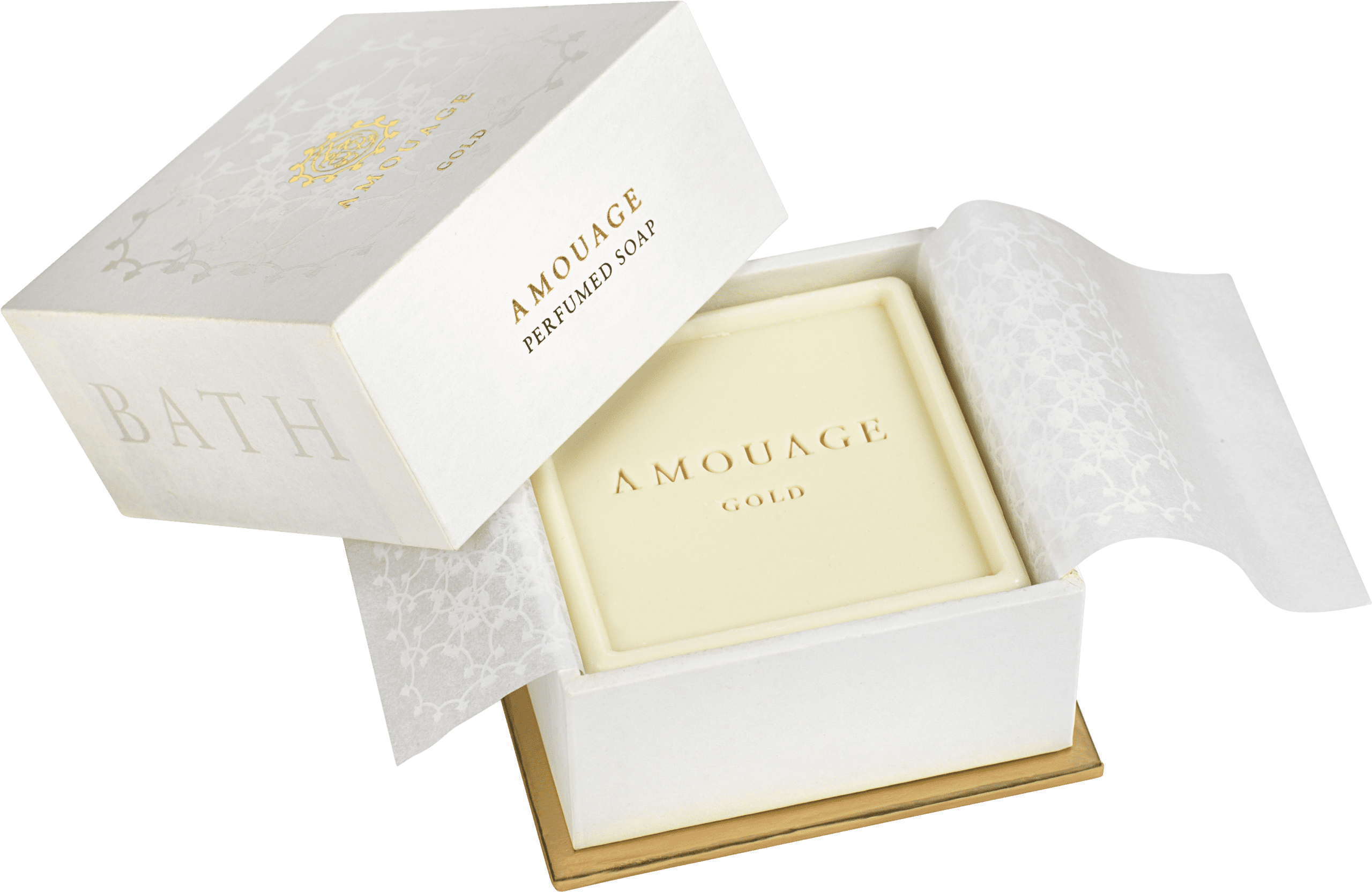

- Classic Design: Opt for classic and timeless designs over trendy aesthetics. Gen Xers often prefer simplicity and sophistication.

Building Brand Loyalty through Consistency

Brand consistency is crucial in maintaining the loyalty of Gen X consumers.

- Consistent Branding: Maintain a consistent brand image across all packaging. Sudden rebrands or drastic design changes might be off-putting.

- Trust and Reliability: Emphasize the reliability and trustworthiness of your brand through your packaging.

Eco-friendly Packaging Options

Incorporate sustainable practices in your packaging strategy.

- Recyclable Materials: Utilize materials that are recyclable or have been recycled.

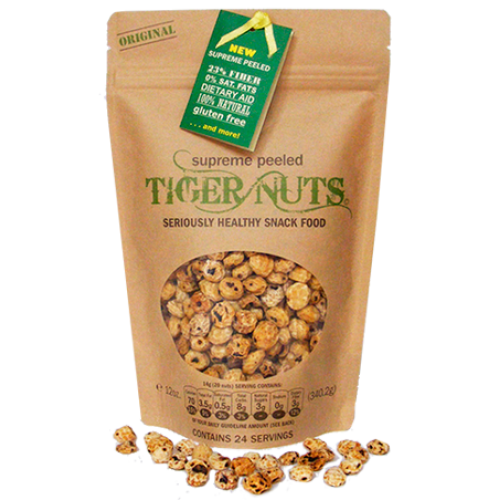

- Minimalist Packaging: Adopt a minimalist approach to reduce waste. Gen Xers appreciate packaging that doesn’t feel excessive or environmentally unfriendly.

Incorporating Technology Smartly

While Gen Xers are comfortable with technology, they don’t necessarily seek it out in packaging.

- QR Codes for Information: Use QR codes sparingly to provide additional product information or instructions.

- Subtle Tech Integration: Any tech features should enhance the functionality or user experience without being overly complicated.

Marketing Through Packaging

Use packaging as a tool for subtle yet effective marketing.

- Promotions and Rewards: Include information about loyalty programs, promotions, or rewards that might appeal to the value-oriented nature of Gen X.

- Testimonials and Ratings: Incorporate customer testimonials or ratings, as Gen X consumers often seek out peer reviews and opinions.

If you are interested in packaging for generation x, then partner with Brown Packaging today to get started.

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Home » Packaging Strategies for Generation X

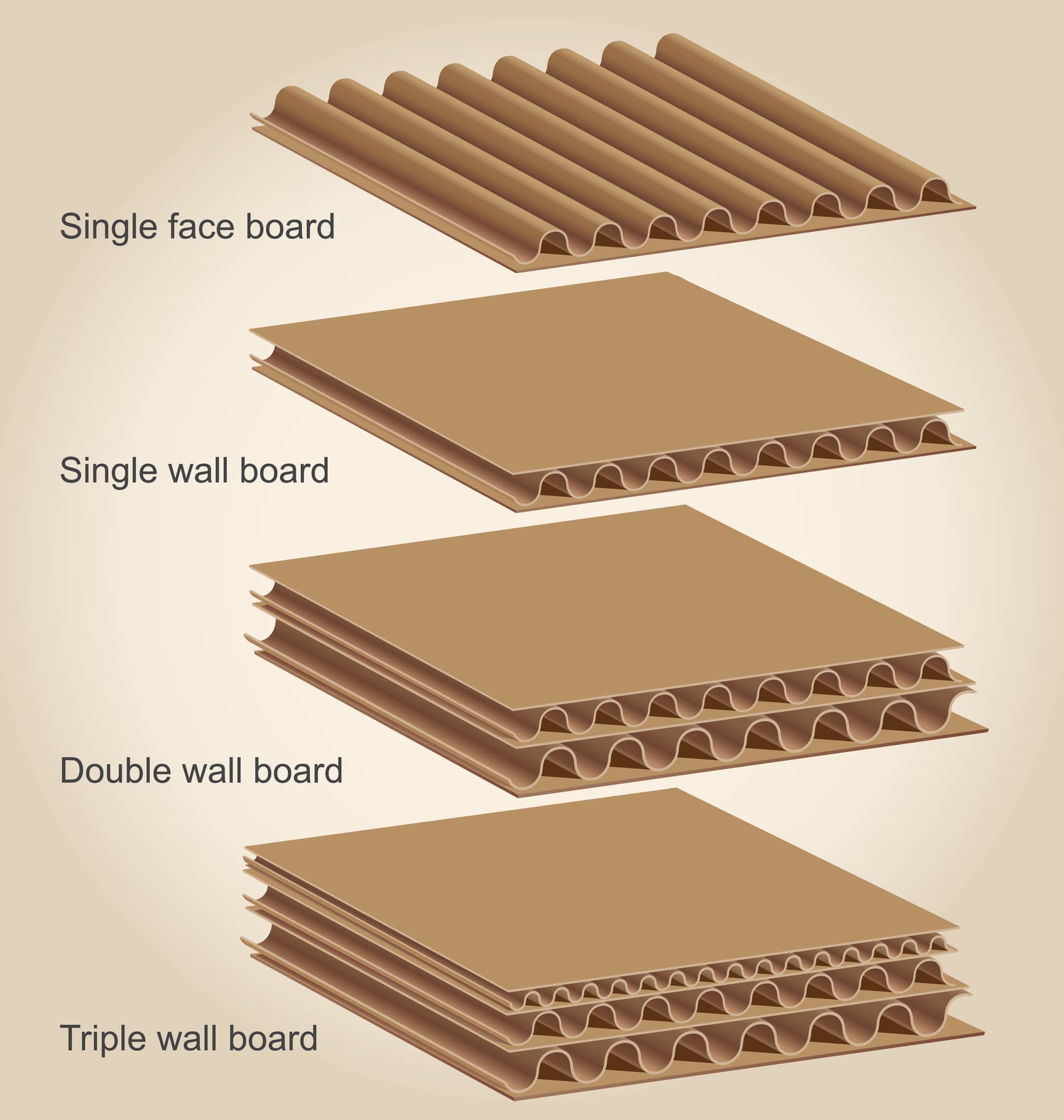

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of

Functional features like tear strips, windows, and hang tabs can enhance consumer experience and retail appeal—but they also introduce engineering challenges. Each modification affects structural

Flexible packaging stands out in the packaging industry for its adaptability and efficiency. Utilizing materials that can flex and mold, this type of packaging adjusts